Method for preparing carbon adsorption material with fish scales

A carbon adsorption and fish scale technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution and resource waste, and achieve high adsorption performance, simple process, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Phosphoric acid activated fish scale carbon adsorption material

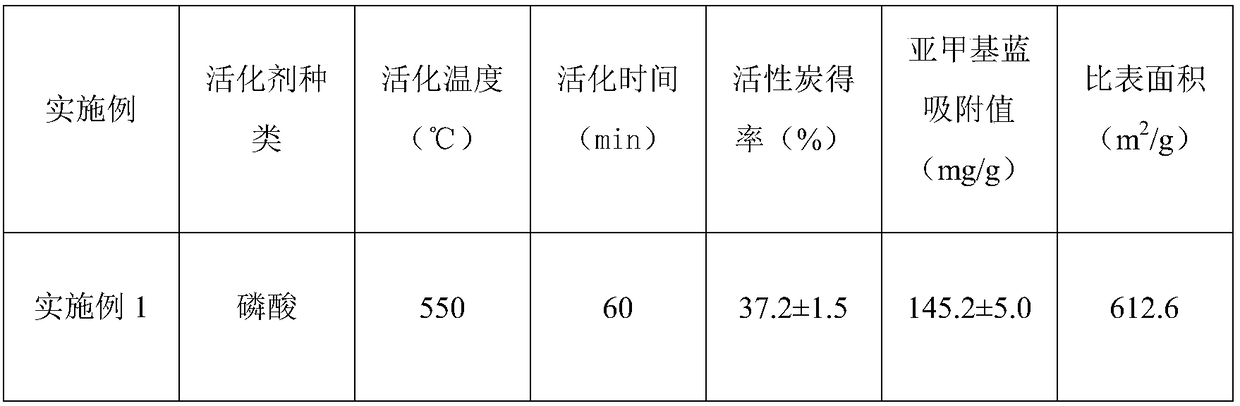

[0020] Weigh 20g of fish scale raw material and mix with 50g of phosphoric acid (concentration 85%) activator, and soak for 15h. Put the fully impregnated material into a box-type resistance furnace, heat up to 550°C at 20°C / min to activate for 60 minutes, take it out after cooling to room temperature, wash it with water for 5 times, filter it, dry it at 110°C for 10 hours, take it out and grind it. After sieving, put the prepared powdered fish scale carbon adsorption material sample into a sample bag for later use. The yield, specific surface area, and methylene blue adsorption value of the resulting product are shown in Table 1.

[0021] Table 1. Product performance of phosphoric acid activated fish scale carbon adsorption material

[0022]

Embodiment 2

[0024] Potassium hydroxide activated fish scale carbon adsorption material

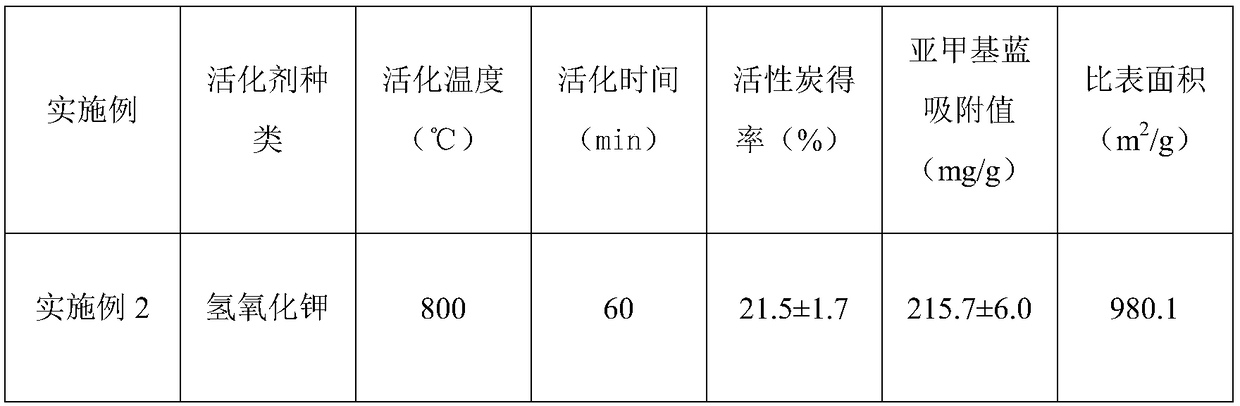

[0025] Weigh 20g of fish scale raw material and mix with 30g of pure potassium hydroxide (formed into a 50% aqueous solution) activator, and soak for 20h. Put the fully impregnated material into a box-type resistance furnace, heat up to 800°C at 20°C / min and activate for 60 minutes, take it out after cooling to room temperature, wash it with water for 5 times, filter, dry at 110°C for 10 hours, take it out and grind, After sieving, put the prepared powdered fish scale carbon adsorption material sample into a sample bag for later use. The yield, specific surface area, and methylene blue adsorption value of the resulting product are shown in Table 2.

[0026] Table 2. Potassium hydroxide activated fish scale carbon adsorption material product performance

[0027]

Embodiment 3

[0029] Zinc chloride activated fish scale carbon adsorption material

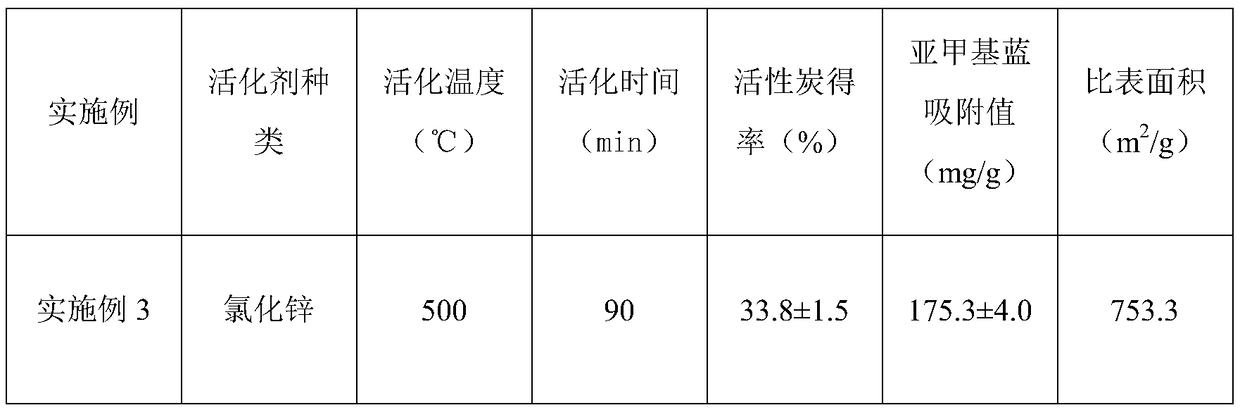

[0030] Weigh 20g of the fish scale raw material and mix with 60g of pure zinc chloride (formed into an aqueous solution with a concentration of 60%) activator, and soak for 24 hours. Put the fully impregnated material into a box-type resistance furnace, heat up to 500°C at 20°C / min and activate for 90 minutes, take it out after cooling to room temperature, wash with water for 5 times, filter, dry at 110°C for 10 hours, take out and grind, After sieving, put the prepared powdered fish scale carbon adsorption material sample into a sample bag for later use. The yield, specific surface area, and methylene blue adsorption value of the resulting product are shown in Table 3.

[0031] Table 3. Product performance of zinc chloride activated fish scale carbon adsorption material

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com