CoMoO4/g-c3n4 composite photocatalyst, and preparation method and application thereof

A technology of g-c3n4 and composite light, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of improved ability, good adsorption ability and degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a g-C 3 N 4 The preparation method of powder: get 5g melamine and place in glass magnetic boat, put the glass magnetic boat that fills melamine into tube furnace then, in N 2 Programmed temperature rise under atmosphere: 0-500, 5°C / min; 500°C, 2h; 500-550, 5°C / min; 550°C, 2h, that is, in the temperature range of 0-500°C at a heating rate of 5°C / min Calcined at 500°C for 2 hours, then heated to 550°C at a rate of 5°C / min in the temperature range of 500-550°C and calcined for 2 hours; after obtaining a light yellow solid, grind it to obtain g-C 3 N 4 powder.

Embodiment 2

[0040] A CoMoO 4 The preparation method of nanorods: weigh 0.24195gNa 2 MoO 4 2H 2 O and 0.29103gCo(NO 3 ) 2 ·6H 2 O was added to 50mL deionized water, stirred for 30min and then ultrasonicated for 10min to obtain a mixed solution; the mixed solution was placed in a 100mL reactor, and reacted at 180°C for 5h; after the reaction, naturally cooled to room temperature, and the precipitate in the reactor was taken out was washed three times with deionized water and absolute ethanol, and finally dried at 60 °C to obtain CoMoO 4 Nano stave.

Embodiment 3

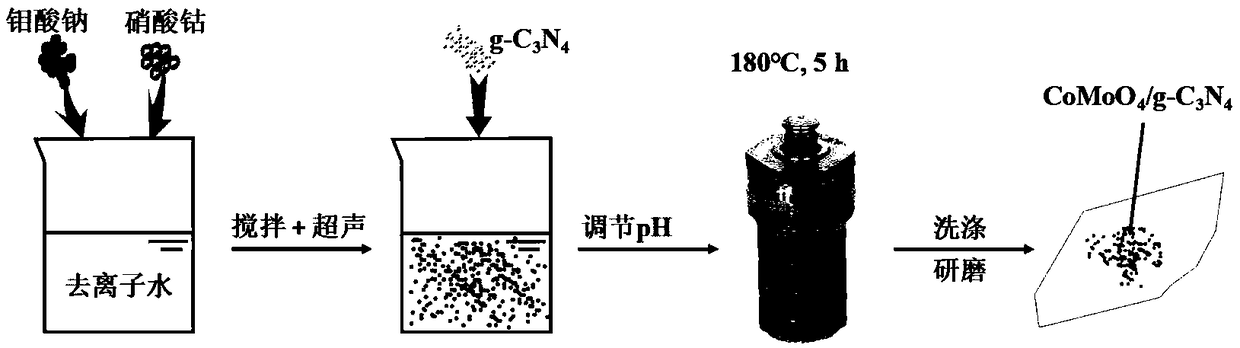

[0042] g-C of the present invention 3 N 4 / CoMoO 4 Preparation method of composite material:

[0043] Step 1, get 5g melamine and place in the glass magnetic boat, put the glass magnetic boat that fills melamine into the tube furnace then, in N 2 Programmed temperature rise under atmosphere: 0-500, 5°C / min; 500°C, 2h; 500-550, 5°C / min; 550°C, 2h, that is, in the temperature range of 0-500°C at a heating rate of 5°C / min Calcined at 500°C for 2 hours, then heated to 550°C at a rate of 5°C / min in the temperature range of 500-550°C and calcined for 2 hours; after obtaining a light yellow solid, grind it to obtain g-C 3 N 4 powder;

[0044] Step 2, weigh 0.24195gNa 2 MoO 4 2H 2 O and 0.29103gCo(NO 3 ) 2 ·6H 2 O was added to 50mL deionized water, stirred for 30min and then ultrasonicated for 10min to obtain the mixed solution A;

[0045] Step 3, weigh 0.2187g of g-C prepared in step 1 3 N 4 Add the powder into the mixed solution A, adjust the pH of the mixed reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com