Organic waste water treatment system for water-based topcoat application technology of equipment coating and method thereof

A technology for organic wastewater treatment and water-based topcoat, which is applied in water/sewage treatment, biological water/sewage treatment, water/sewage treatment equipment, etc., and can solve the problems of unorganized discharge, easy generation of odor, hazardous sludge waste, etc. , to achieve the effect of saving equipment and increasing irradiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

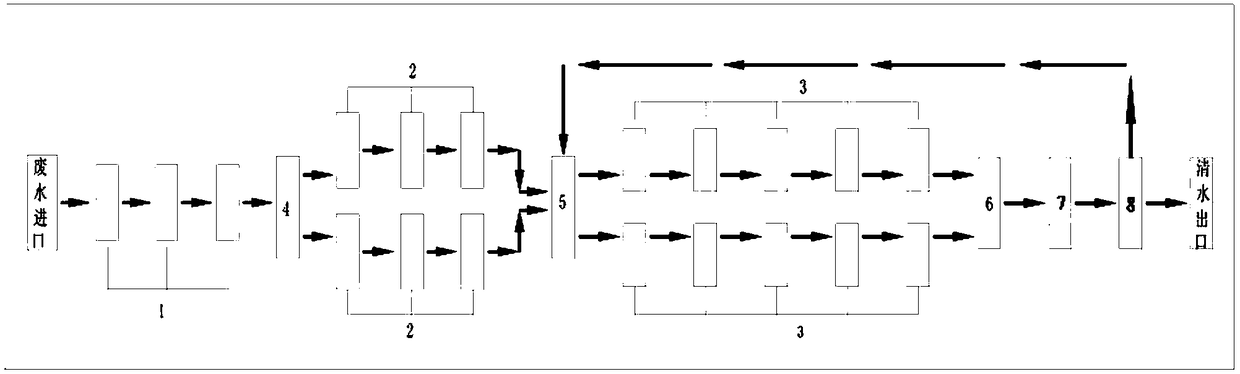

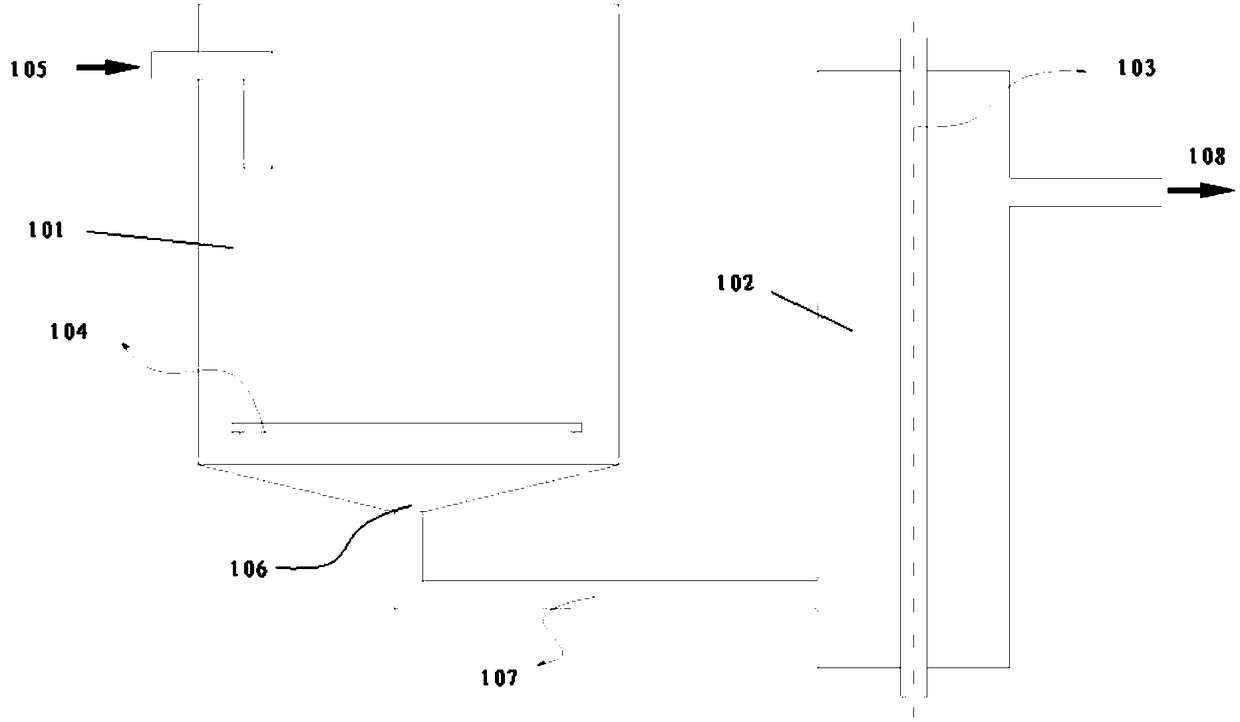

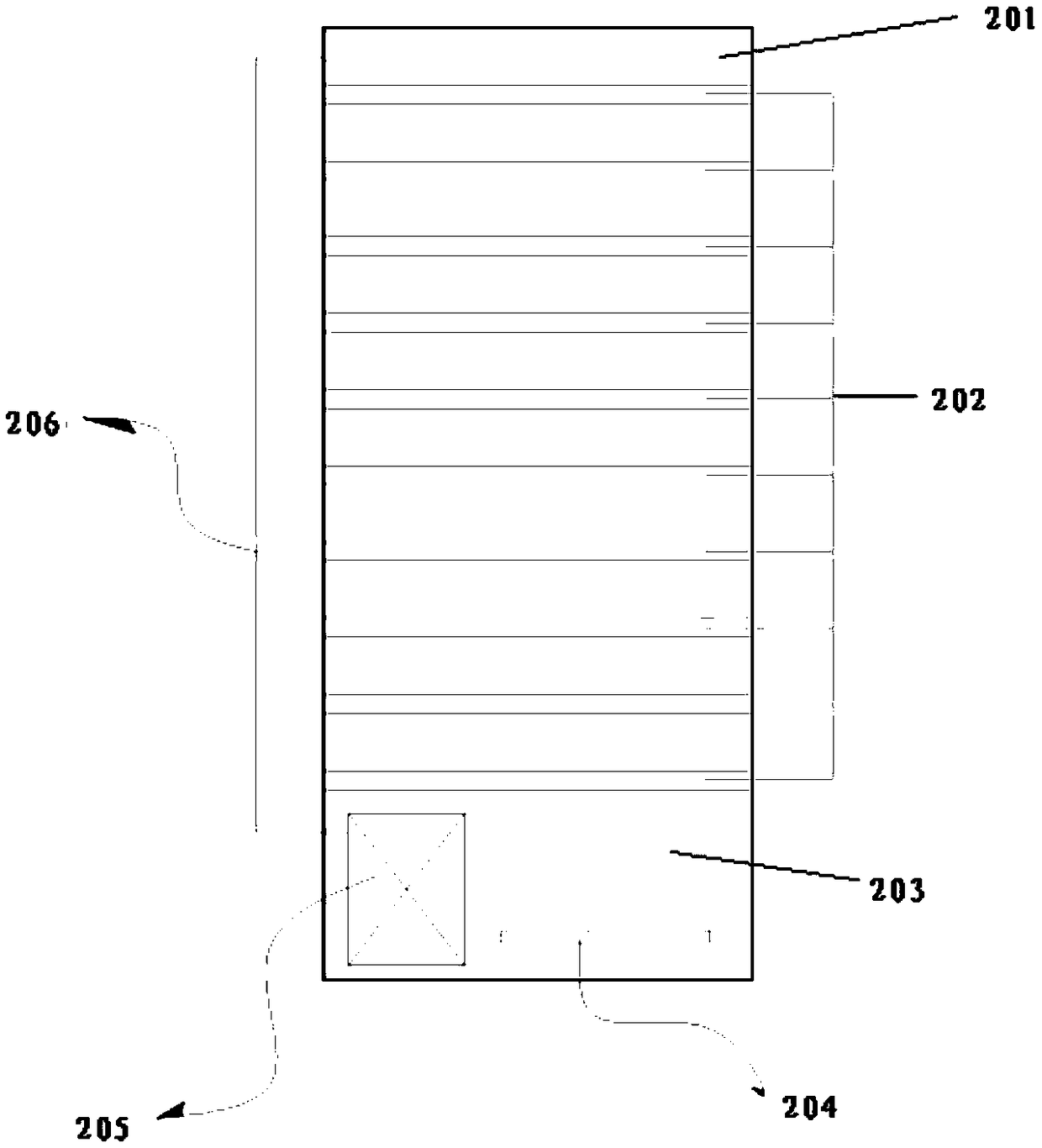

[0100] An embodiment of the organic wastewater treatment system for the equipment coating water-based topcoat process of the present invention, the structural diagram is shown in figure 1 The organic wastewater treatment system of the equipment coating water-based topcoat process includes a photocatalytic reaction system and a biochemical treatment system; the photocatalytic system includes an overflow ultraviolet photocatalytic reaction device 1, a trickle ultraviolet photocatalytic reactor 2 and Biochemical treatment system 3; the overflow ultraviolet photocatalytic reaction device 1 is connected to the trickle ultraviolet photocatalytic reactor 2 through the diversion water tank 4, and the water outlet of the drip ultraviolet photocatalytic reactor 2 is deposited with the inclined tube device (not shown in the figure), bag filter (not shown in the figure), dilution water tank 5 and biochemical treatment system 3 are connected successively, and the water outlet of described b...

Embodiment 2

[0143] A kind of embodiment of the organic wastewater treatment method of equipment coating water-based topcoat process of the present invention, described method comprises the following steps:

[0144] (1), while the organic wastewater of the equipment coating water-based topcoat process is carried out oxygen-increasing treatment, the over-flow ultraviolet photocatalytic treatment is carried out. Pass compressed air into the organic waste water, the dissolved oxygen in the organic waste water after the aeration and oxygen enhancement treatment is 8~14mg / L; the temperature in the organic waste water after the described aeration and oxygen enhancement treatment is 1~ 10°C; the ultraviolet light is dual-band ultraviolet light with wavelengths of 185nm and 254nm respectively;

[0145] (2), the organic wastewater after the over-flow type ultraviolet photocatalytic treatment is subjected to trickle ultraviolet photocatalytic treatment; the trickle ultraviolet photocatalytic treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com