The production process of one-step production of methyl anthranilate

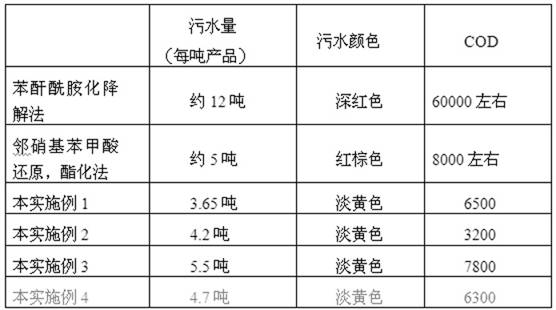

A technology of methyl anthranilate and a production process, which is applied in the field of production technology for producing methyl anthranilate by one-step method, can solve the problems of low esterification yield and large pollution, and achieves less environmental pollution and less waste water. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the present invention provides a kind of one-step method to produce the production technique of methyl anthranilate, specifically comprises the following steps:

[0017] (1) Add 18.2g of N-chlorophthalimide, 6.4g of methanol and 40g of water into a three-necked flask, then lower the temperature to below 0°C, and stir to make a slurry.

[0018] (2) Add 16.2g of 30% sodium hydroxide aqueous solution dropwise, after dropping, keep the temperature below 0°C and stir for 20 minutes;

[0019] (3) After raising the temperature to 50-80° C. for one hour, the temperature was naturally lowered, and the layers were separated for ten hours, and the product 13.8 g of methyl anthranilate was obtained in the lower layer. The product purity is 99.8%, and the yield is 91.4%.

Embodiment 2

[0020] Embodiment 2: the present invention provides a kind of one-step method to produce the production technique of methyl anthranilate, specifically comprises the following steps:

[0021] (1) Add 18.2g of N-chlorophthalimide, 64g of methanol and 40g of water into a three-necked flask, then lower the temperature to below 0°C, and stir for beating.

[0022] (2) Add 40g of 30% sodium hydroxide aqueous solution dropwise, after dropping, keep the temperature below 0°C and stir for 20 minutes;

[0023] (3) After raising the temperature to 50-80°C and reacting for one hour, the methanol was distilled off under reduced pressure, then the temperature was naturally lowered, and the mixture was allowed to stand for ten hours to separate the layers, and the product 14.0 g of methyl anthranilate was obtained in the lower layer. The product purity is 99.5%, and the yield is 92.7%.

Embodiment 3

[0024] Embodiment 3: the present invention provides a kind of one-step method to produce the production technique of methyl anthranilate, specifically comprises the following steps:

[0025] (1) Add 91g of N-chlorophthalimide, 80g of methanol and 200g of water into a three-necked flask, then lower the temperature to below 0°C, and stir for beating.

[0026] (2) Add 200g of 30% sodium hydroxide aqueous solution dropwise, after dropping, keep the temperature below 0°C and stir for 20 minutes;

[0027] (3) Raise the temperature to 50-80°C and react for one hour, then lower the temperature naturally, let stand for ten hours and separate into layers, and the product 70g of methyl anthranilate can be obtained in the lower layer. The product purity is 99.8%, and the yield is 92.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com