Regeneration treatment liquid of titanium anode for electrolytic copper foil, preparation method of regeneration treatment liquid and titanium anode regeneration method

A technology for regenerating treatment liquid and electrolytic copper foil, which is applied in the field of regeneration of titanium anodes, and can solve problems such as harmful iridium-tantalum oxide coatings, low scaling removal efficiency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

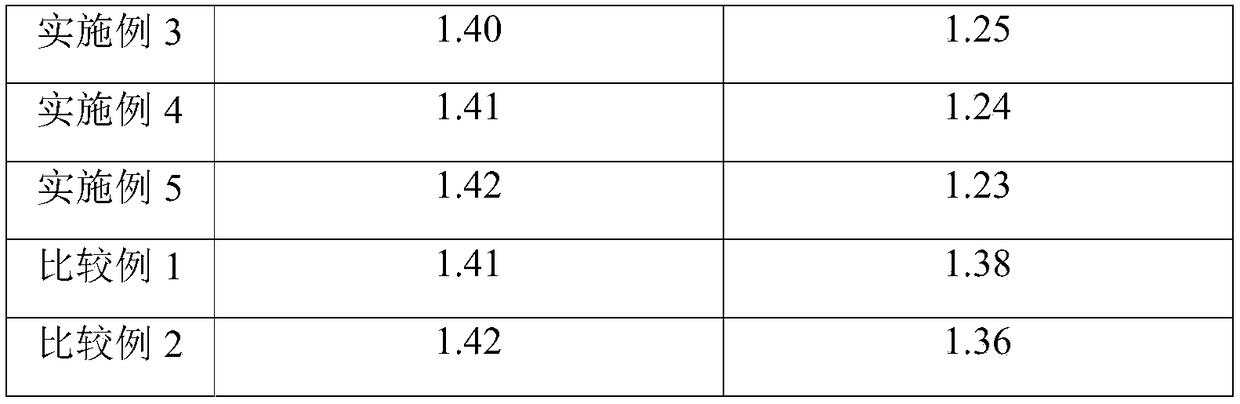

Examples

Embodiment 1

[0013] Slowly dissolve sodium acetate in deionized water, slowly add an aqueous solution of ammonium acetate under stirring conditions, then add an aqueous solution of nonylphenol polyoxyethylene ether (NP-10), and mix well after stirring to obtain an electrolytic copper foil Use the regeneration treatment solution of titanium anode, the concentration of sodium acetate in the regeneration treatment solution is 30g / L, the concentration of ammonium acetate is 50g / L, and the concentration of nonylphenol polyoxyethylene ether (NP-10) is 0.01g / L. After cleaning the used titanium-based iridium-tantalum oxide coated titanium anode plate with a fouling layer on the surface with deionized water, place it in the regeneration treatment solution prepared at a temperature of 60°C, and place it under ultrasonic vibration After soaking for 60 minutes under the same conditions, the scale layer on the surface of the titanium-based iridium-tantalum oxide-coated titanium anode plate can be remove...

Embodiment 2

[0015] Slowly dissolve sodium acetate in deionized water, slowly add an aqueous solution of ammonium acetate under stirring conditions, then add an aqueous solution of nonylphenol polyoxyethylene ether (NP-10), and mix well after stirring to obtain an electrolytic copper foil Use the regeneration treatment solution of titanium anode, the concentration of sodium acetate in the regeneration treatment solution is 50g / L, the concentration of ammonium acetate is 100g / L, and the concentration of nonylphenol polyoxyethylene ether (NP-10) is 0.05g / L. After cleaning the used titanium-based iridium-tantalum oxide coated titanium anode plate with a fouling layer on the surface with deionized water, place it in the regeneration treatment solution prepared at a temperature of 50°C, and place it under ultrasonic vibration After soaking for 45 minutes under the same conditions, the scale layer on the surface of the titanium-based iridium-tantalum oxide coated titanium anode plate can be remov...

Embodiment 3

[0017] Slowly dissolve sodium acetate in deionized water, slowly add an aqueous solution of ammonium acetate under stirring conditions, then add an aqueous solution of nonylphenol polyoxyethylene ether (NP-10), and mix well after stirring to obtain an electrolytic copper foil Use the regeneration treatment solution of titanium anode, the concentration of sodium acetate in the regeneration treatment solution is 75g / L, the concentration of ammonium acetate is 150g / L, and the concentration of nonylphenol polyoxyethylene ether (NP-10) is 0.1g / L. After cleaning the used titanium-based iridium-tantalum oxide coated titanium anode plate with a fouling layer on the surface with deionized water, place it in the regeneration solution prepared at a temperature of 45°C, and under the condition of ultrasonic vibration After soaking for 30 minutes, the scaling layer on the surface of the titanium-based iridium-tantalum oxide-coated titanium anode plate can be removed, and the regeneration tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com