Nanocrystallization coating preparation method utilizing linear/annular microplasma discharge self-balancing technology

A micro-plasma, self-balancing technology, applied in the direction of surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve the problems of direct application difficulties and achieve the effects of eliminating violent eruption effects, improving microhardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Material preparation: After the 5A02 aluminum alloy is cut and polished, it is cleaned and degreased by ultrasonic waves in acetone solution.

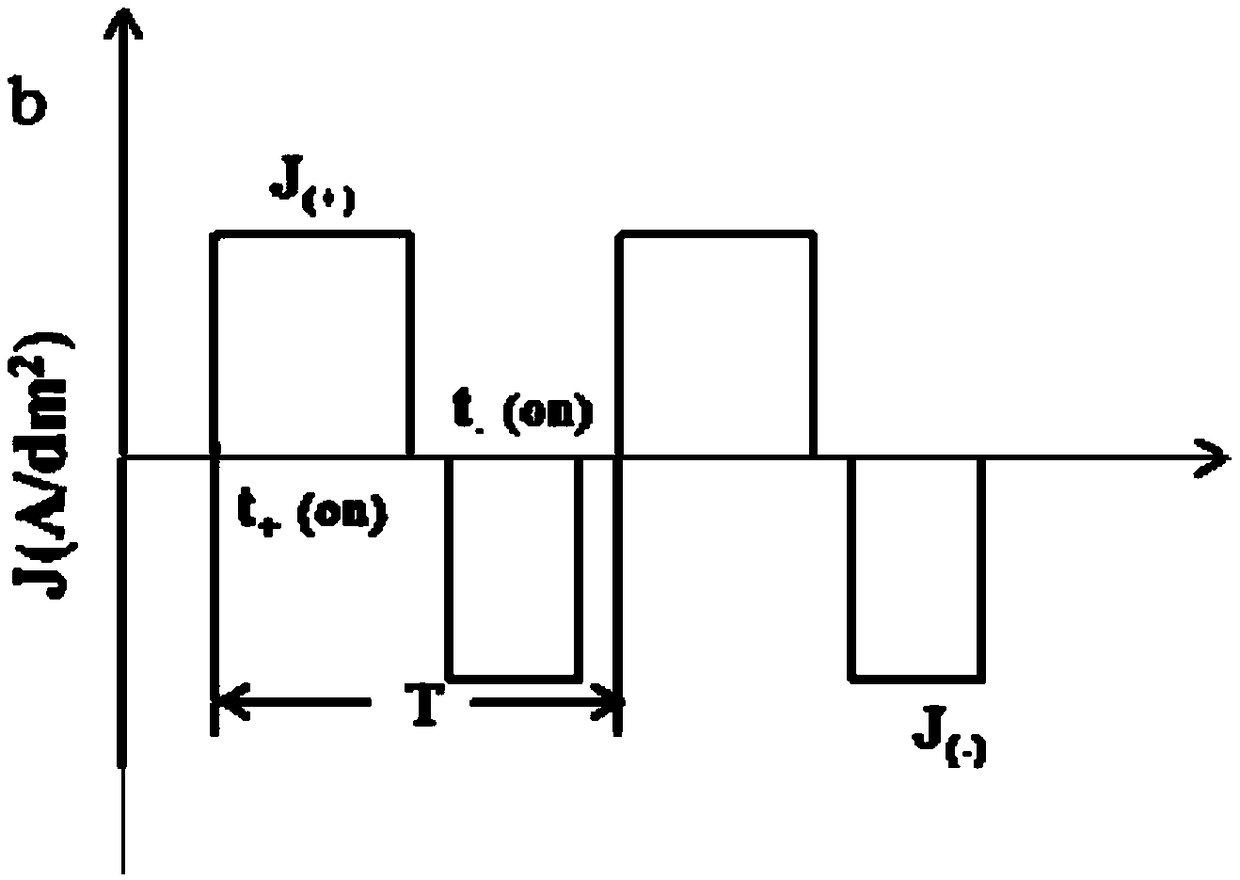

[0047] 2. For voltage control waveform diagram, see figure 1 , the voltage control mode is within one cycle:

[0048] Forward voltage 10 ~ 500V, duty cycle 50%;

[0049] Voltage 0V, duty cycle 10%;

[0050] Negative voltage 10~300V, duty cycle 30%;

[0051] Voltage 0V, duty cycle 10%.

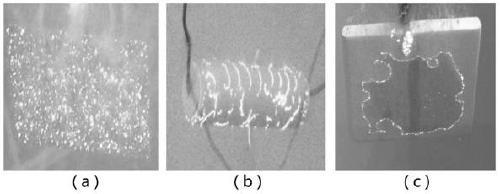

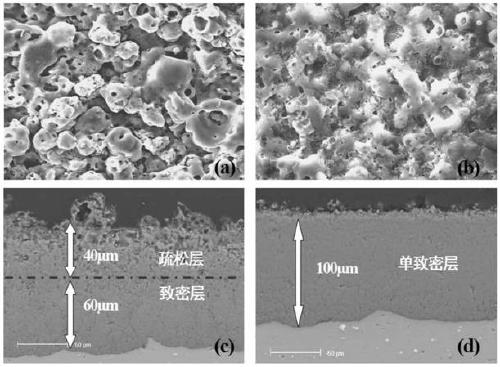

[0052] 3. The construction of nano-scale point-like plasma discharge sparks is as follows: the shape of plasma discharge sparks is adjusted from micron-scale sprays to nano-scale white dots; the specific solution parameters are:

[0053] Main salt (sodium gluconate) 8-10g / L; pH regulator (sodium hydroxide) 2g / L; additive (sodium aluminate) 1-2g / L; stabilizer (sodium silicate) 3-5g / L; Cellulose 1g / L; water is the balance.

[0054] The electrical parameters are:

[0055] Oxidation time: 0-90 minutes; Forward voltage: 10-500V; Forward curr...

Embodiment 2

[0073] 1. Material preparation: After the 2024 aluminum alloy is cut and polished, it is cleaned and degreased by ultrasonic waves in acetone solution.

[0074] 2. The voltage control method is within one cycle:

[0075] Forward voltage 10 ~ 550V, duty cycle 70%;

[0076] Voltage 0V, duty cycle 5%;

[0077] Negative voltage 10~150V, duty cycle 20%;

[0078] Voltage 0V, duty cycle 5%.

[0079] 3. The construction of nano-scale point-like plasma discharge sparks is as follows: the shape of plasma discharge sparks is adjusted from micron-scale jets to nano-scale white dots. The specific solution parameters are:

[0080] Main salt (sodium gluconate) 8-10g / L; pH regulator (sodium hydroxide) 2g / L; additive (sodium aluminate) 1-2g / L; stabilizer (sodium silicate) 3-5g / L; Cellulose 1g / L; water is the balance.

[0081] The electrical parameters are:

[0082] Oxidation time: 0-100 minutes; Forward voltage: 10-550V; Forward current density: 1-4A / cm 2 ;Negative voltage: 10~150V; Neg...

Embodiment 3

[0097] 1. Material preparation: After the 7075 aluminum alloy is cut and polished, it is cleaned and degreased by ultrasonic waves in acetone solution.

[0098] 2. The voltage control method is within one cycle:

[0099] Forward voltage 10 ~ 500V, duty cycle: 60%;

[0100] Voltage 0V, duty cycle 10%;

[0101] Negative voltage 10~130V, duty cycle 20%;

[0102] Voltage 0V, duty cycle 10%.

[0103] 3. The construction of the nano-scale point plasma discharge spark is as follows: the shape of the plasma discharge spark is adjusted from a micron-scale spray shape to a nano-scale white point shape. The specific solution parameters are:

[0104] Main salt (sodium gluconate) 0~10g / L; pH regulator (sodium hydroxide) 0~2g / L; additive (sodium aluminate) 1.5~3g / L; stabilizer (sodium silicate) 2~4g / L L; Cellulose 1~3g / L;

[0105] The electrical parameters are:

[0106] Oxidation time 0-140 minutes; forward voltage 10-500V; forward current density 2-5A / cm 2 ; Negative voltage 10~130V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Surface vickers hardness | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com