Temperature Control System of Gridded Concrete Dam

A concrete dam and temperature control system technology, which is applied in the field of concrete dam project operation temperature control, water conservancy and hydropower project construction, can solve problems such as time lag, concrete temperature out of control, and inability to protect in advance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

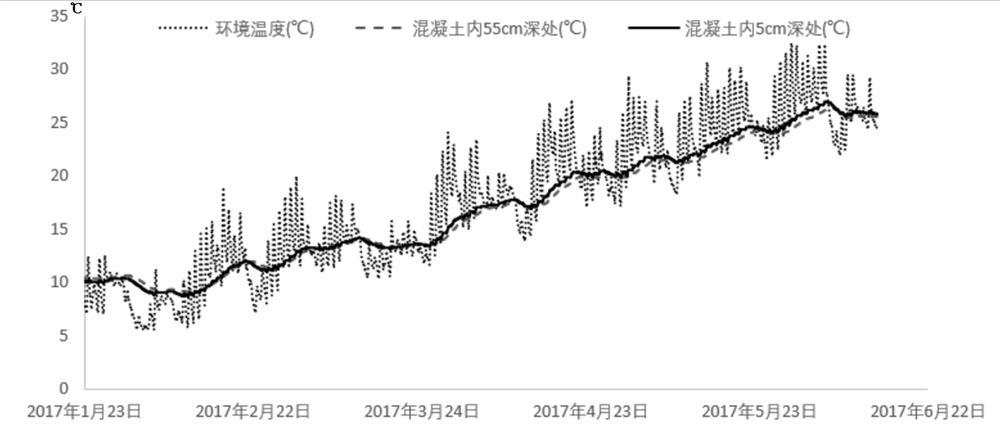

[0102] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

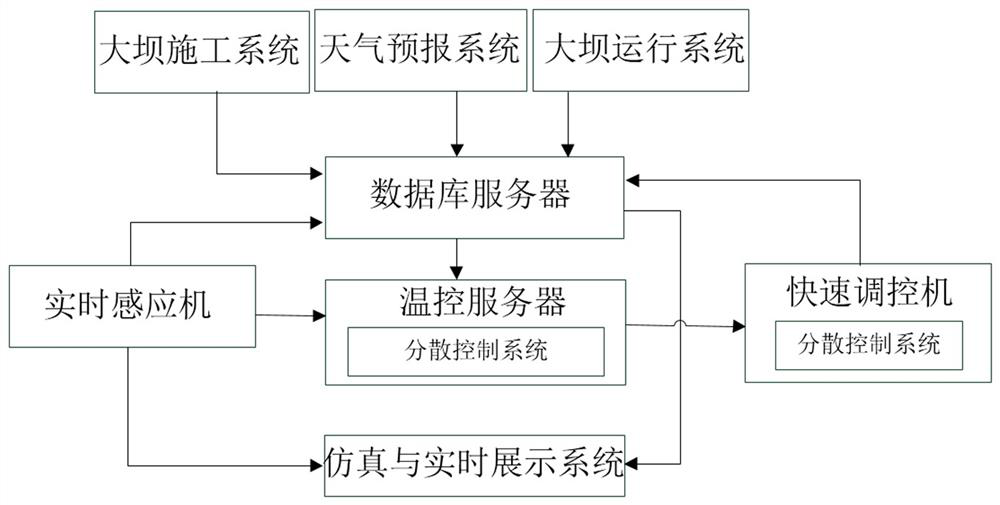

[0103] like image 3 As shown, the gridded dam temperature control system includes a real-time induction machine 2, a temperature control server, and a fast control machine 3 connected in sequence, and also includes a database server, a database server and a dam construction system, a weather forecast system, and a dam operation system connect.

[0104] like Figure 5 As shown, the fast control machine 3 includes 2 industrial computers 31, 2 temperature compensation sources 32, 3 PLC controllers, a variable topology pipe network 33 and a wireless base station 34, and the variable topology pipe network 33 includes gridded A plurality of six-way control units 331, a temperature compensation source 32, a PLC controller, and a wireless base station 34 are connected to the industrial computer 31 respectively, and the six-way control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com