Method for evaluating equipment applicability of nuclear power plant security level instrumentation and control system

An instrument control system and safety-level technology, which is applied in the applicability field of safety-level instrument control system equipment in nuclear power plants, can solve problems such as inability to analyze applicability, and achieve the effect of facilitating programming and shortening the appraisal cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

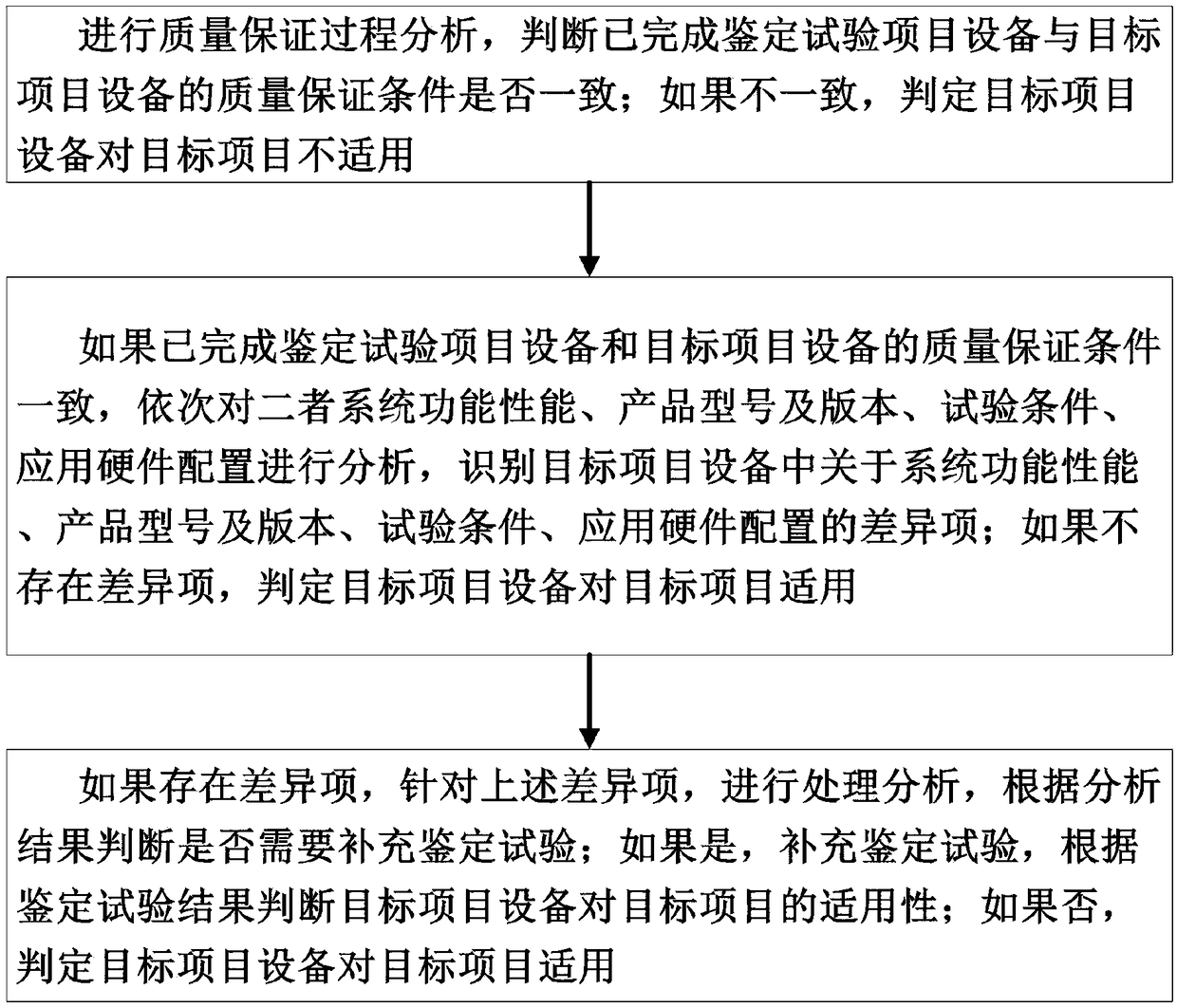

[0069] A specific embodiment of the present invention discloses a method for identifying the applicability of nuclear power plant safety-level instrument and control system equipment, such as figure 1 shown, including the following steps:

[0070] S1. Conduct quality assurance process analysis. Judging whether the quality assurance conditions of the equipment of the completed appraisal test project and the equipment of the target project are consistent; if not, it is judged that the equipment of the target project is not applicable to the target project.

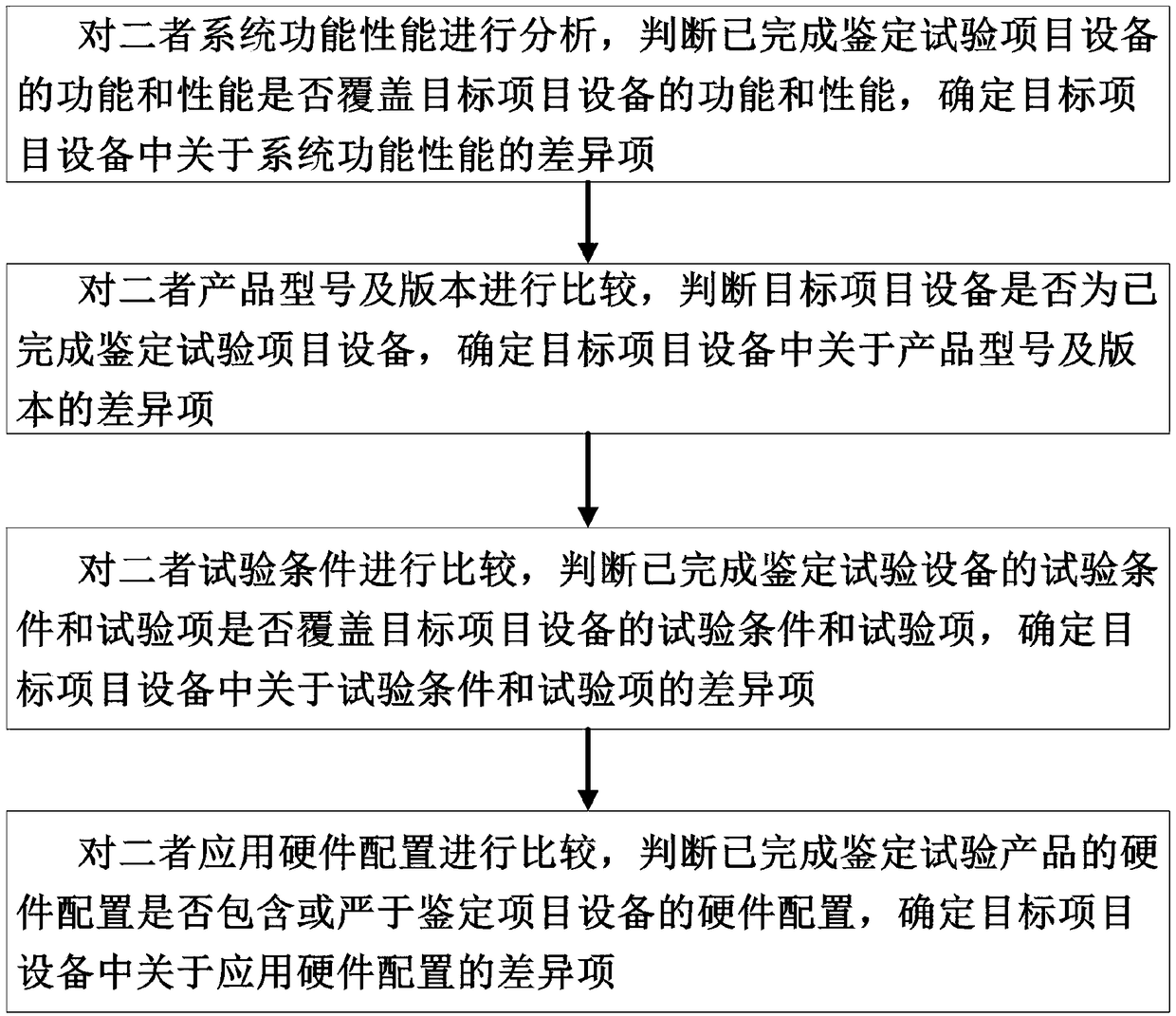

[0071] S2. If the quality assurance conditions of the equipment that has completed the appraisal test project and the equipment of the target project are consistent, analyze the system function performance, product model and version, test conditions, and application hardware configuration of the two in turn, and identify the functional performance of the system in the equipment of the target project , product model and vers...

Embodiment 2

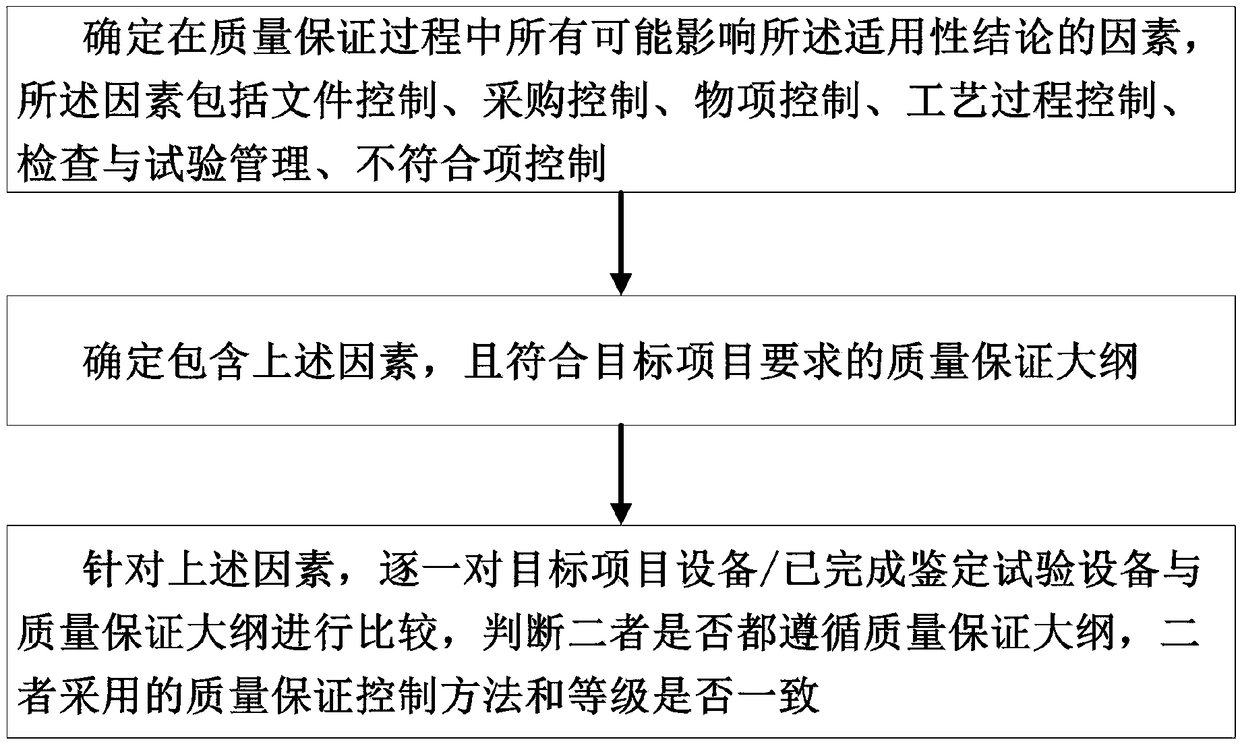

[0075]Optimizing on the basis of Example 1, such as figure 2 As shown, step S1 can be further refined into the following steps:

[0076] S11. Determine all factors that may affect the suitability conclusion in the quality assurance process, and the factors include document control, procurement control, item control, process control, inspection and test management, and non-conformity item control.

[0077] S12. Determine the quality assurance program that includes the above factors and meets the requirements of the target project.

[0078] S13. In view of the above factors, compare the target project equipment / completed appraisal test equipment with the quality assurance program one by one to judge whether both follow the quality assurance program, and whether the quality assurance control methods and levels adopted by the two are consistent.

[0079] Preferably, step S12 is based on the HAF003 "Nuclear Power Plant Quality Assurance Safety Regulations" regulations and relevan...

Embodiment 3

[0115] A specific example of applying the method described in Example 2 for applicability analysis is given below.

[0116] The first step is to analyze the quality assurance process. According to the safety-level product design and manufacturing quality assurance program, the quality assurance level of the target project equipment is Q1, and its quality management system requirements meet HAF003. The quality control is the whole process quality supervision, and the completed Verify that the safety-level product design is consistent with the manufacturing quality assurance requirements. Therefore, proceed to step S2.

[0117] In the second step, the system function performance analysis is carried out first. The target project equipment (FirmSys platform) includes conditioning and isolation functions, analog IO functions, digital IO functions, IO communication functions, computing processing functions, hot standby redundancy functions, and data link functions. 9 major function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com