A bonding pad for vertical interconnection with a ceramic circuit substrate BGA and a manufacturing method thereof

A technology for circuit substrates and ceramics, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of large shear stress, thermal expansion coefficient difference, reliability research and optimization are not in-depth, etc., to improve shear strength, increase Soldering area, the effect of high reliability BGA interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

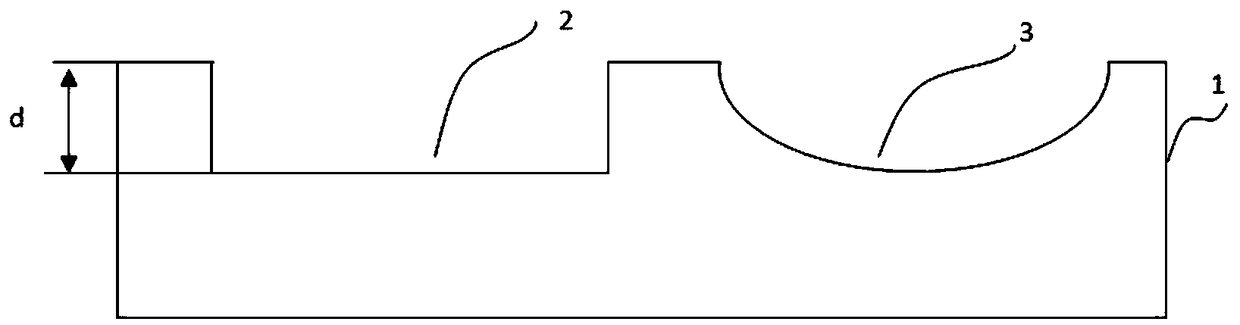

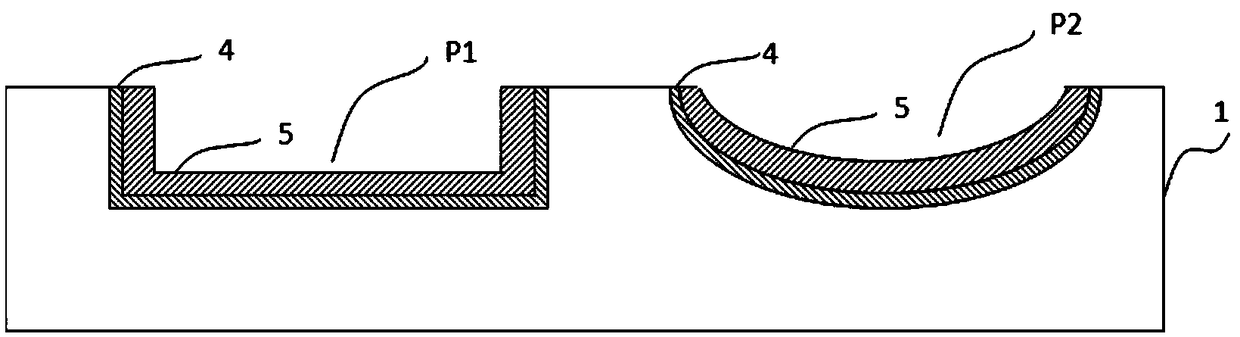

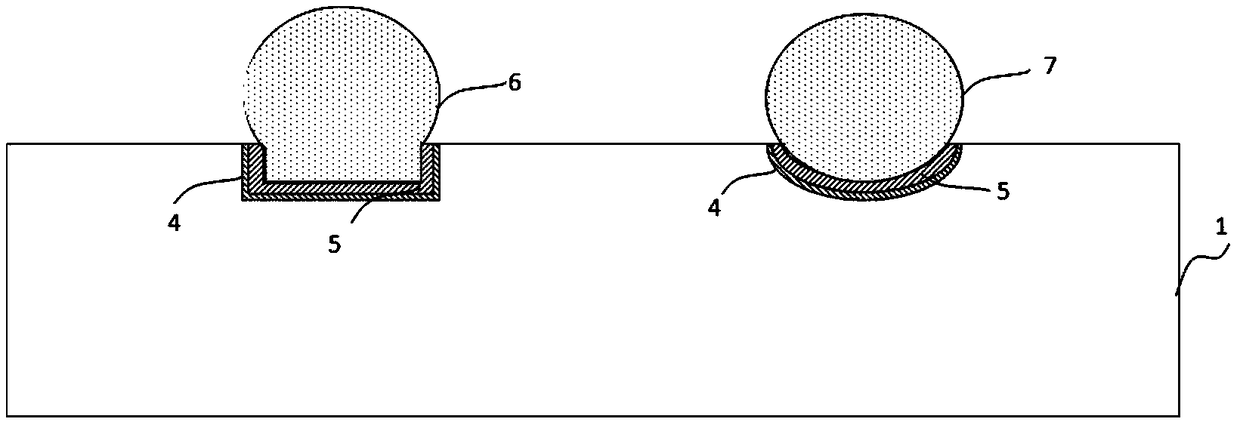

[0035] Such as figure 1 and figure 2 As shown, a pad for vertical interconnection of a ceramic circuit substrate BGA includes pits, a metallized seed layer 4 and a metallized film layer 5, the pits are arranged on the surface of the ceramic circuit substrate 1, and the pits The vertical section can be arc-shaped or polygonal, such as rectangular pit 2, arc-shaped pit 3, the metallized seed layer 4 is arranged on the surface of the pit, and the metallized film layer 5 is arranged on the surface of the pit. The surface of the seed layer 4 is metallized.

[0036] In the above technical solution, due to the design of the pit structure, the pads are concave downwards and have a three-dimensional structure, which can better clamp the solder balls and increase the soldering area, improve the shear strength of the solder balls, and achieve high reliability of the ceramic circuit board. BGA interconnection. The pad structure does not change the circuit layout and electrical transmi...

experiment example 1

[0052] Experimental Example 1 The influence of the three-dimensional structure pad of the present invention on the shear force of BGA balls

[0053] 1. BGA ball shear force test welded with three-dimensional structure pads of the present invention

[0054] 1) The LTCC substrate of Dupont's 9K7 system is used as the processing object, and the total thickness of the substrate is 1.5mm. A pit with a depth of d=17 μm is processed on the surface of the substrate by laser etching, and the diameter of the pit is 0.6 mm;

[0055] 2) Make a metallized seed layer on the pit by thin film sputtering process, the total thickness of the seed layer is 260nm, the composition is Ti thickness 75nm, W thickness 75nm, Au thickness 110nm;

[0056] 3) A metallization layer for tin-lead soldering is made on the seed layer by using an electroless plating process, and the components are a Ni layer with a thickness of 4 μm, a Pd layer with a thickness of 0.1 μm, and an Au layer with a thickness of 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com