A high-efficiency cadmium telluride thin film solar cell

A solar cell, cadmium telluride technology, applied in circuits, electrical components, photovoltaic power generation and other directions, can solve the problem of low transmittance of incident light, and achieve simple process, high light transmittance and power added value, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

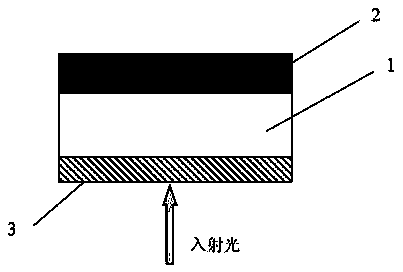

[0017] A cadmium telluride thin-film solar cell includes a glass substrate 1, a cadmium telluride thin-film power generation layer 2, and an anti-reflection and anti-reflection film 3. The anti-reflection and anti-reflection film 3 is a silicon oxide film prepared by a sol-gel method with a refractive index of 1.15. The thickness is 200nm; through the battery power test, the power generation efficiency of the cadmium telluride thin film solar cell increased by 3.5% compared with the previous one after coating the anti-reflection and anti-reflection film 3.

Embodiment 2

[0019] A cadmium telluride thin-film solar cell includes a glass substrate 1, a cadmium telluride thin-film power generation layer 2, and an anti-reflection and anti-reflection film 3. The anti-reflection and anti-reflection film 3 is a magnesium fluoride film prepared by evaporation, with a refractive index of 1.27. The thickness is 125nm; after the battery power test, the power generation efficiency of the cadmium telluride thin film solar cell increased by 3.6% compared with the previous one after coating the anti-reflection and anti-reflection film 3.

Embodiment 3

[0021] A cadmium telluride thin-film solar cell includes a glass substrate 1, a cadmium telluride thin-film power generation layer 2, and an anti-reflection and anti-reflection film 3. The anti-reflection and anti-reflection film 3 is a titanium oxide film prepared by magnetron sputtering, with a refractive index of 1.5 , with a thickness of 45nm; through the battery power test, the power generation efficiency of the cadmium telluride thin-film solar cell increased by 3.2% compared with the previous one after coating the anti-reflection and anti-reflection film 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com