An iron-based catalyst for alkaline fuel cell and a preparation method thereof

An iron-based catalyst and fuel cell technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory catalytic efficiency, complicated preparation process, and low catalytic activity, and achieve improved catalytic decomposition ability, simple preparation process, The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

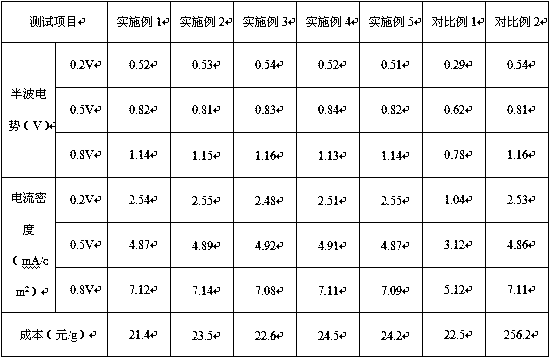

Examples

Embodiment 1

[0031] a. Adding multi-walled carbon nanotube powder, glucose and sodium dodecylsulfonate to deionized water, stirring and mixing, and ultrasonic dispersion to obtain a black suspension;

[0032] b, adding ferric nitrate to the black suspension obtained in step a, sealing the solution after slight stirring, performing heat treatment, further centrifuging, washing, and drying to obtain iron-based multi-walled carbon nanotube powder;

[0033] c. Put the iron-based multi-walled carbon nanotube powder prepared in step b in a vacuum furnace, and use a gas-loaded nitrogen source to perform high-temperature plasma heat treatment to prepare a modified iron-based catalyst.

[0034] In step a, the stirring speed is 250r / min, the frequency of ultrasonic dispersion is 70kHz, and the time is 30min; in step b, the speed of slight stirring is 25r / min, the time is 2min, stirring in the same direction, and the temperature of heat treatment is 200°C , the time is 12h; in step c, the plasma gas ...

Embodiment 2

[0037] a. Adding multi-walled carbon nanotube powder, glucose and sodium dodecylsulfonate to deionized water, stirring and mixing, and ultrasonic dispersion to obtain a black suspension;

[0038] b, adding ferric nitrate to the black suspension obtained in step a, sealing the solution after slight stirring, performing heat treatment, further centrifuging, washing, and drying to obtain iron-based multi-walled carbon nanotube powder;

[0039] c. Put the iron-based multi-walled carbon nanotube powder prepared in step b in a vacuum furnace, and use a gas-loaded nitrogen source to perform high-temperature plasma heat treatment to prepare a modified iron-based catalyst.

[0040] In step a, the stirring speed is 200r / min, the frequency of ultrasonic dispersion is 60kHz, and the time is 40min; in step b, the speed of slight stirring is 20r / min, the time is 3min, stirring in the same direction, and the temperature of heat treatment is 180°C , the time is 15h; in step c, the plasma gas so...

Embodiment 3

[0043] a. Adding multi-walled carbon nanotube powder, glucose and sodium dodecylsulfonate to deionized water, stirring and mixing, and ultrasonic dispersion to obtain a black suspension;

[0044] b, adding ferric nitrate to the black suspension obtained in step a, sealing the solution after slight stirring, performing heat treatment, further centrifuging, washing, and drying to obtain iron-based multi-walled carbon nanotube powder;

[0045] c. Put the iron-based multi-walled carbon nanotube powder prepared in step b in a vacuum furnace, and use a gas-loaded nitrogen source to perform high-temperature plasma heat treatment to prepare a modified iron-based catalyst.

[0046] In step a, the stirring speed is 300r / min, the frequency of ultrasonic dispersion is 80kHz, and the time is 20min; in step b, the rotating speed of slight stirring is 30r / min, and the time is 2min, stirring in the same direction, and the temperature of heat treatment is 200 °C, the time is 10; in step c, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com