Fermented soybean meal with low pectin content as well as preparation method and application thereof

A technology for fermenting soybean meal and pectinase preparation, applied to bacteria used in food preparation, application, animal feed, etc., can solve the problems of low pectin content, long fermentation time of soybean meal, low pectin removal rate, etc., and achieve fermentation short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

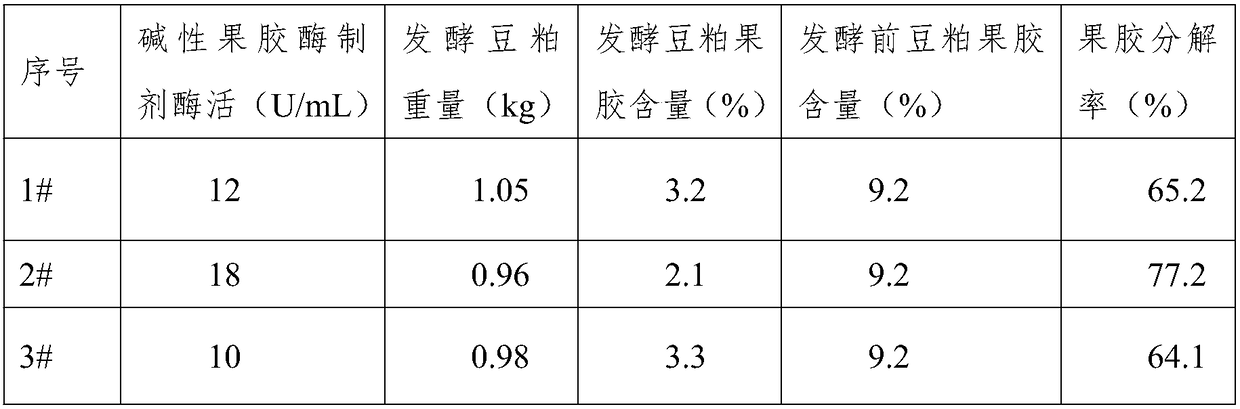

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing fermented soybean meal with low pectin content, comprising the following steps:

[0036] 1) Preparation of alkaline pectinase preparation: take commercially available alkaline pectinase (Hunan Lierkang Biological Co., Ltd., commercial enzyme: alkaline pectinase 1500U, labeled alkaline pectinase activity 1500U / mL) 1 liter was added to 9 liters of water, and stirred evenly to obtain 10 liters of alkaline pectinase preparation (solution) with an enzyme activity of about 150 U / mL.

[0037] 2) Slowly heat the above-mentioned alkaline pectinase preparation to 45°C, then slowly add sodium hydroxide solution with a mass concentration of 5%, and adjust its pH value to 9.0.

[0038] 3) Add 10 kg of soybean meal raw material (commercially available, with a pectin content of 8.6%) to the above-mentioned 10 liters of alkaline pectinase preparation, mix well to obtain about 20 kg of soybean meal slurry, and keep it warm at 45° C. for 2 ...

Embodiment 2

[0044] This embodiment provides a method for preparing fermented soybean meal with low pectin content, comprising the following steps:

[0045]1) Inject the activated Bacillus licheniformis (purchased from China Industrial Microorganism Culture Collection Management Center, No. CICC 21942) into sterilized 1000mL culture medium (the composition of the culture medium is 5.0g peptone) according to the inoculation amount of 2%. , beef extract 3.0g, NaCl 5.0g, soybean meal 2g, corn flour 5g, distilled water about 1000mL; among them, the pH value is 7.0), after aerobic fermentation at 37°C for 24 hours, the enzyme activity is about 16U / mL of alkaline pectinase preparation (solution) is about 1 liter.

[0046] 2) Slowly heat the above-mentioned alkaline pectinase preparation to 40° C., then slowly add sodium hydroxide solution with a mass concentration of 3%, and adjust its pH value to 9.5.

[0047] 3) Add 1 kg of soybean meal raw material (commercially available, with a pectin con...

Embodiment 3

[0055] This embodiment provides a method for preparing fermented soybean meal with low pectin content, comprising the following steps:

[0056] 1) Insert the activated Bacillus amyloliquefaciens (purchased from China Industrial Microorganism Culture Collection and Management Center, No. CICC 23059) into the sterilized 1000mL culture medium (the composition of the culture medium is peptone 5.0 g, beef extract 3.0g, NaCl 5.0g, soybean meal 3g, corn flour 7g, distilled water about 1000mL; where the pH value is 6.8), after aerobic fermentation at 37°C for 36 hours, the enzyme activity is about 15U / mL The alkaline pectinase preparation (solution) is about 1 liter.

[0057] 2) Slowly heat the above-mentioned alkaline pectinase preparation to 40° C., then slowly add sodium hydroxide solution with a mass concentration of 5%, and adjust its pH value to 10.

[0058] 3) Then, add 1 kg of soybean meal raw material (commercially available, with a pectin content of 8.9%) to the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com