Plant essential oil chitosan nano microcapsule as well as preparation method and application thereof

A chitosan nanometer, plant essential oil technology, applied in microcapsule preparation, microsphere preparation, essential oil/spice and other directions, can solve the problem of low utilization efficiency of plant essential oil, lack of plant essential oil, and unable to fully reflect the economic value of plant essential oil and other problems to achieve the effect of prolonging the effect time, improving economic value, and overcoming odor stimulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 Preparation of nano-microcapsules

[0047] 1. Preparation of nano-microcapsule materials

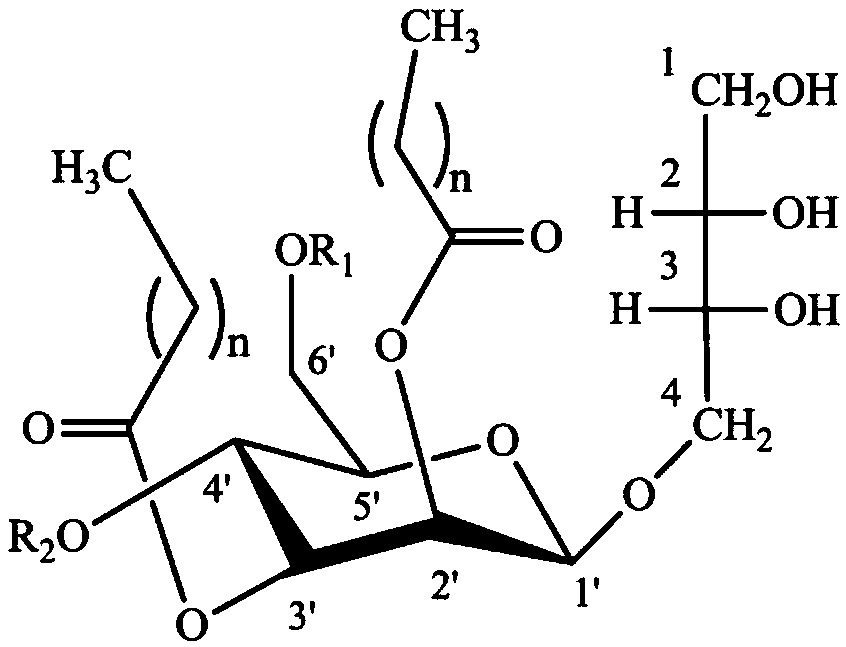

[0048] 1. Production and purification of mannose erythritol lipid

[0049] Mannose erythritol lipid was produced by Pseudozyma aphidis DSM70725 (purchased from German Collection of Microorganisms and Cells). The production and purification method of type A mannose erythritol lipid (MEL-A): first inoculate Torulopsis aphids into the activation culture containing 3% yeast extract, 3% malt extract, 10% glucose and 5% peptone Medium, and cultivated at 28°C and 180rpm for 36 hours. After activation, inoculate 1mL of bacterial culture into NaNO 3 3g / L, MgSO 4 ·7H 2 O 0.3g / L, KH 2 PO 4 Seed medium composed of 0.3g / L, yeast extract 1g / L, glucose 40g / L and distilled water. After 2 days of cultivation at 28°C and 180 rpm, the seed culture was centrifuged and washed twice with saline. The resulting cells were inoculated in 80 mL / L soybean oil containing MgSO 4 ·7H 2...

Embodiment 2

[0058] Embodiment 2 Characterization of nano-microcapsules

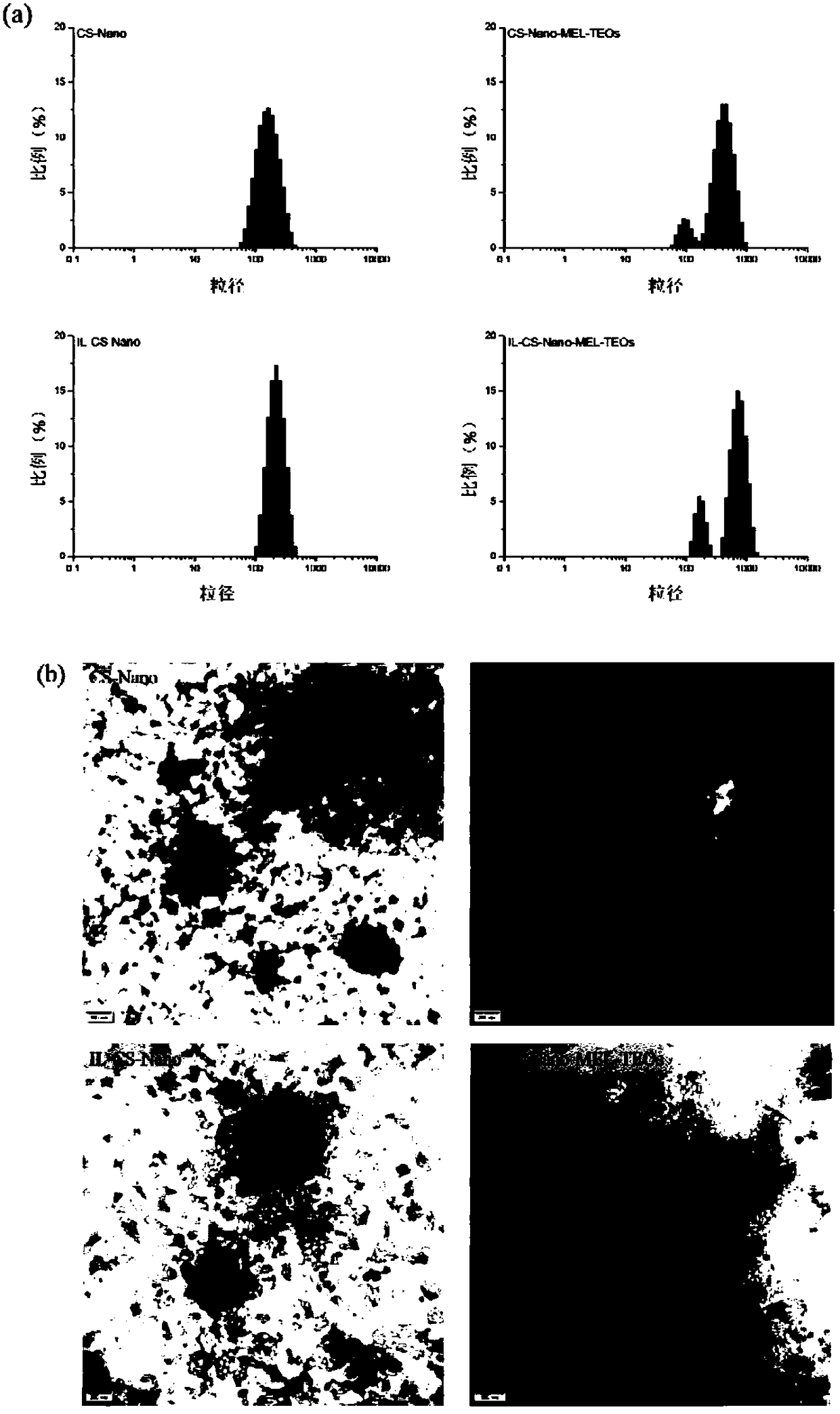

[0059] 1. Characterization of physical and chemical properties of nano-microcapsules

[0060] Particle size distribution and zeta potential:

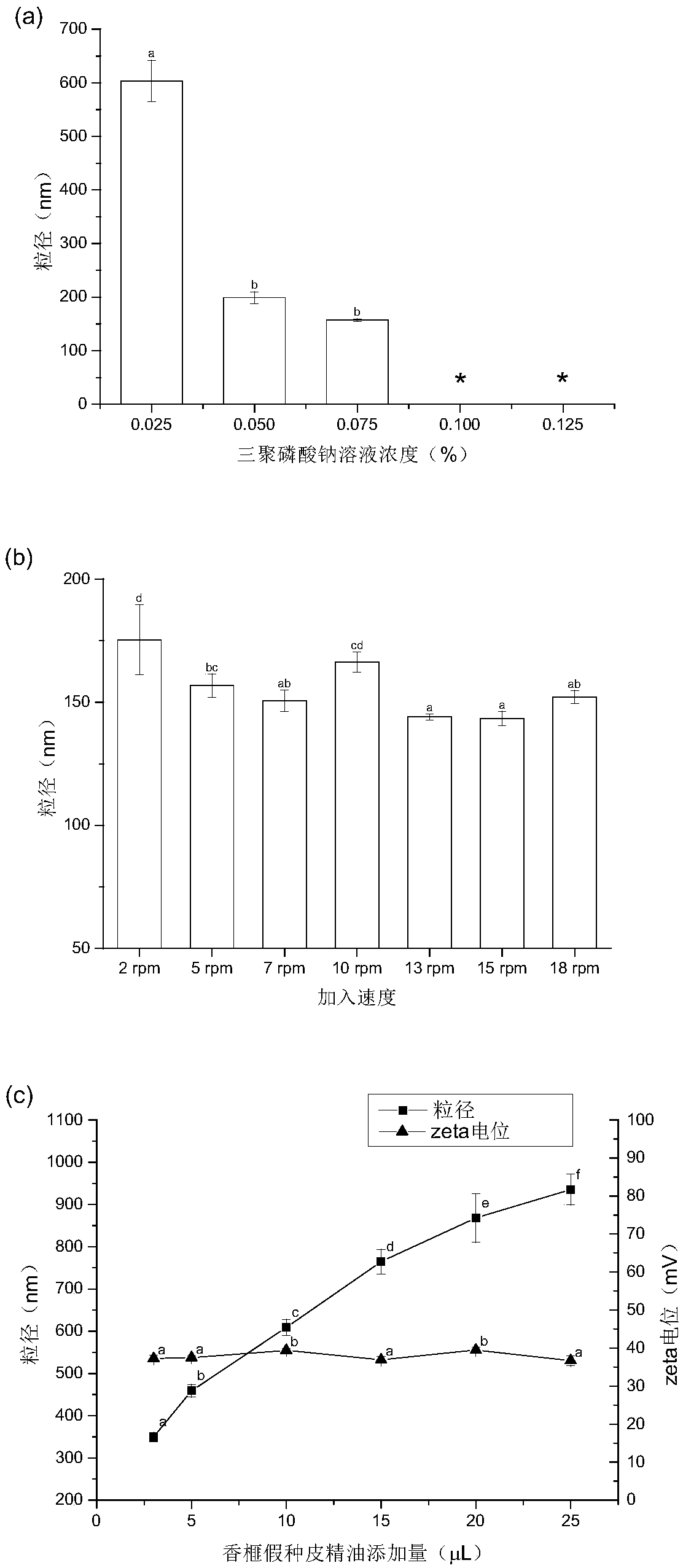

[0061] The particle size distribution, dispersion index and zeta potential of the nanocapsules were determined by dynamic light scattering (DLS) at a wavelength of 633 nm adapted to a Zetasizer Nano ZS90 (Malvern Instruments Ltd, Malvern, UK). The temperature was set at 25°C, and the measurement angle was 90°.

[0062] From figure 2 In a, we can see that when the concentration of sodium tripolyphosphate is lower than 0.075%, the particle size of empty nano-microcapsules decreases with the increase of sodium tripolyphosphate concentration, and the minimum is 157.4±2.2nm at 0.075%. When the concentration of sodium tripolyphosphate is further increased, the sample becomes unstable and settles rapidly.

[0063] The concentration of sodium tripolyphosphate was determined to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com