A kind of nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber electrolysis water catalyst and preparation method thereof

A technology of co-doping and carbon fiber, which is applied in chemical instruments and methods, physical/chemical process catalysts, electrolytic components, etc., can solve the problems of poor catalyst stability and low electrolysis efficiency, and achieve cost savings, increased activity and stability, The effect of a simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

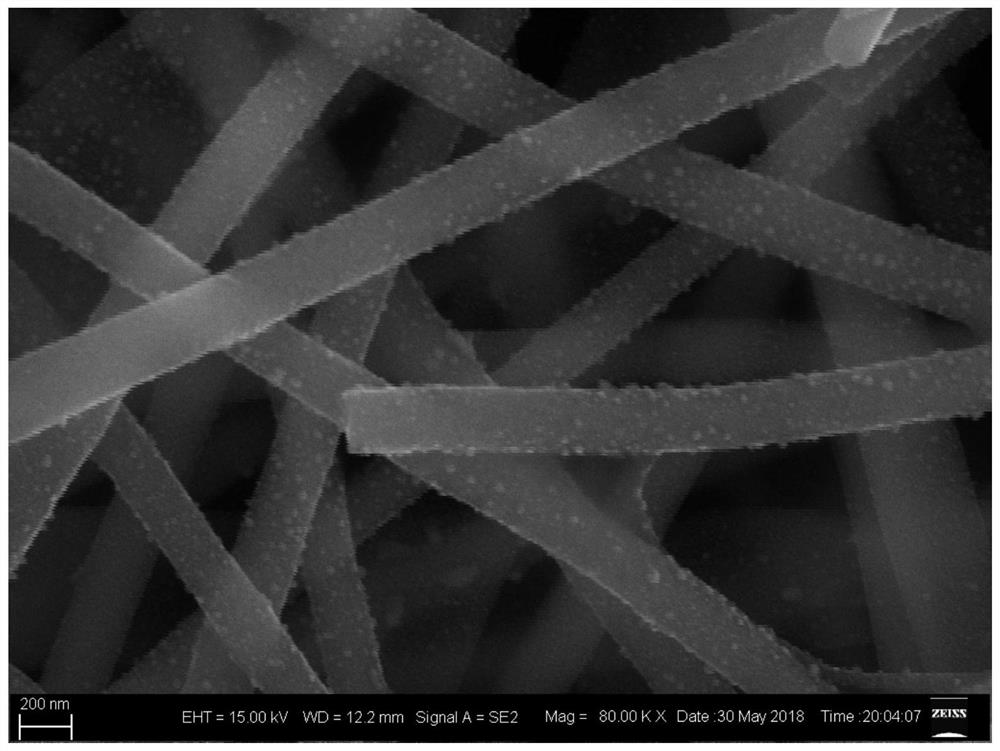

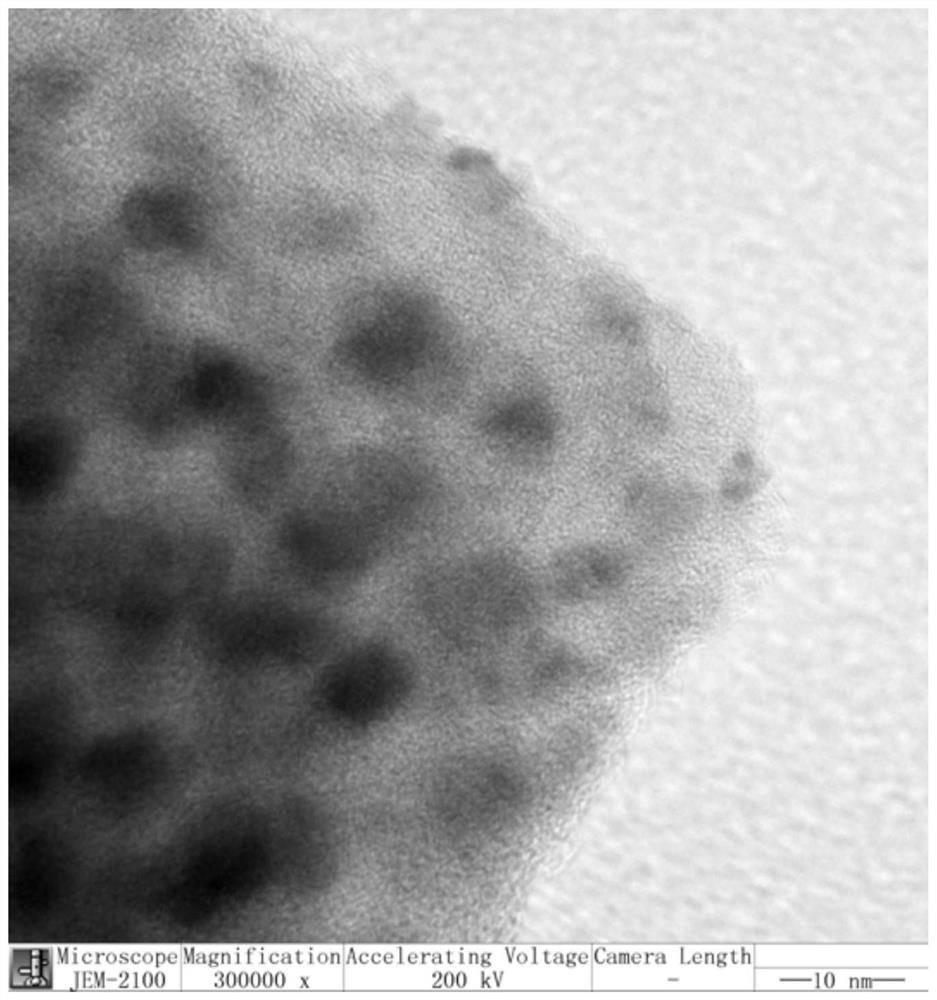

[0035] Embodiment 1: The nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber catalyst for water electrolysis in this embodiment is composed of a carbon fiber matrix and nanoparticles; the nanoparticles are supported inside and on the surface of the carbon fiber matrix; the nanoparticles are nickel-cobalt nitrides and nickel-cobalt sulfides, nickel-cobalt nitrides have the formula Ni x Co y N z , in the molecular formula, x is 1~2, y is 1~2, z is 1~2; the molecular formula of nickel cobalt sulfide is Ni a Co b S c , in the molecular formula, a is 1-2, b is 1-2, and c is 1-2.

[0036] This embodiment has the following beneficial effects:

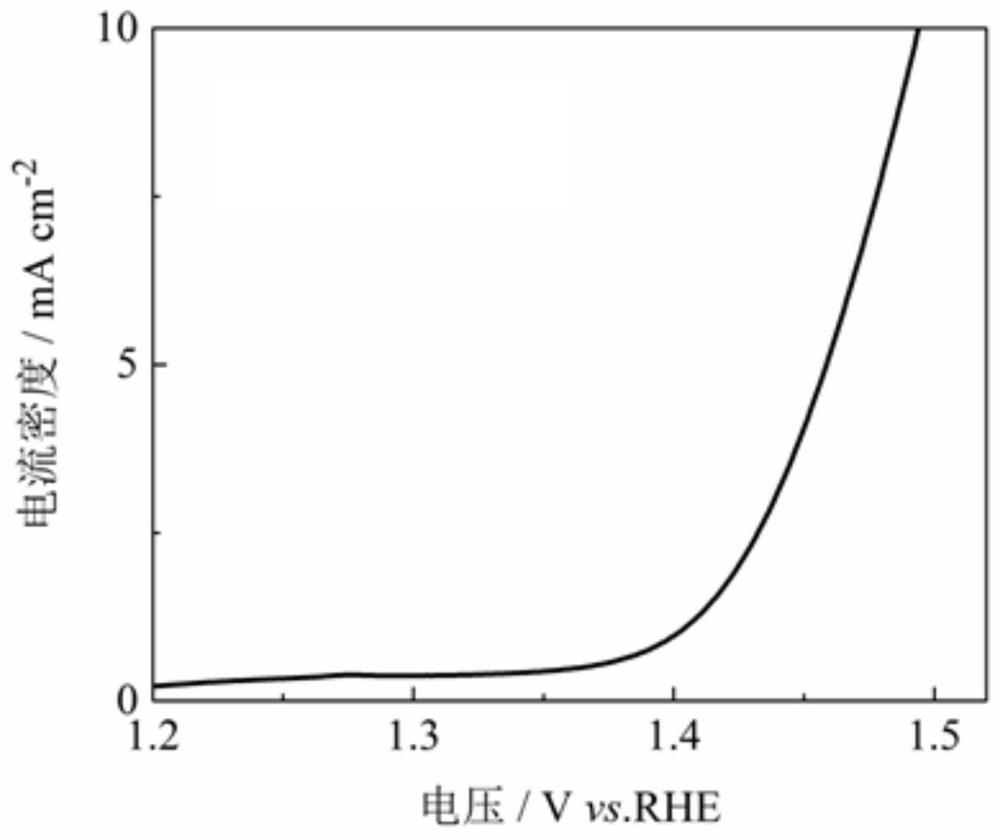

[0037] 1. Ni and Co in the nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber catalyst material for water electrolysis in this embodiment have unfilled valence layer d orbitals, so they have catalytic effects on hydrogen evolution and oxygen evolution reactions, and then Save costs in the actual produ...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particle size of the nanoparticles is 3-7 nm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the preparation method of nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber catalyst for water electrolysis in this embodiment is carried out according to the following steps:

[0042] 1. Preparation of electrospinning precursor solution:

[0043] According to the molecular formula Ni x Co y N z and Ni a Co b S c The molar ratio of each element in the nickel nitrate, cobalt nitrate and thioamide compound was weighed as raw materials, and the weighed raw materials were added to N,N-dimethylformamide to obtain mixed solution a, which was mixed with uniform magnetic stirring at room temperature. Liquid a until the raw materials are completely dissolved, then add polyvinylpyrrolidone to obtain mixed liquid b, and uniformly magnetically stir mixed liquid b for 4 to 6 hours to obtain a completely dissolved transparent electrospinning precursor liquid; molecular formula Ni x Co y N z where x is 1-2, y is 1-2, z is 1-2; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com