Electron-grade hydrogen fluoride preparation procedure

A hydrogen fluoride, electronic-grade technology, applied in the direction of hydrogen fluoride, fluorine/hydrogen fluoride, chemical instruments and methods, etc., can solve problems such as safety accidents, fluorine gas is highly toxic, and increase the difficulty and cost of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

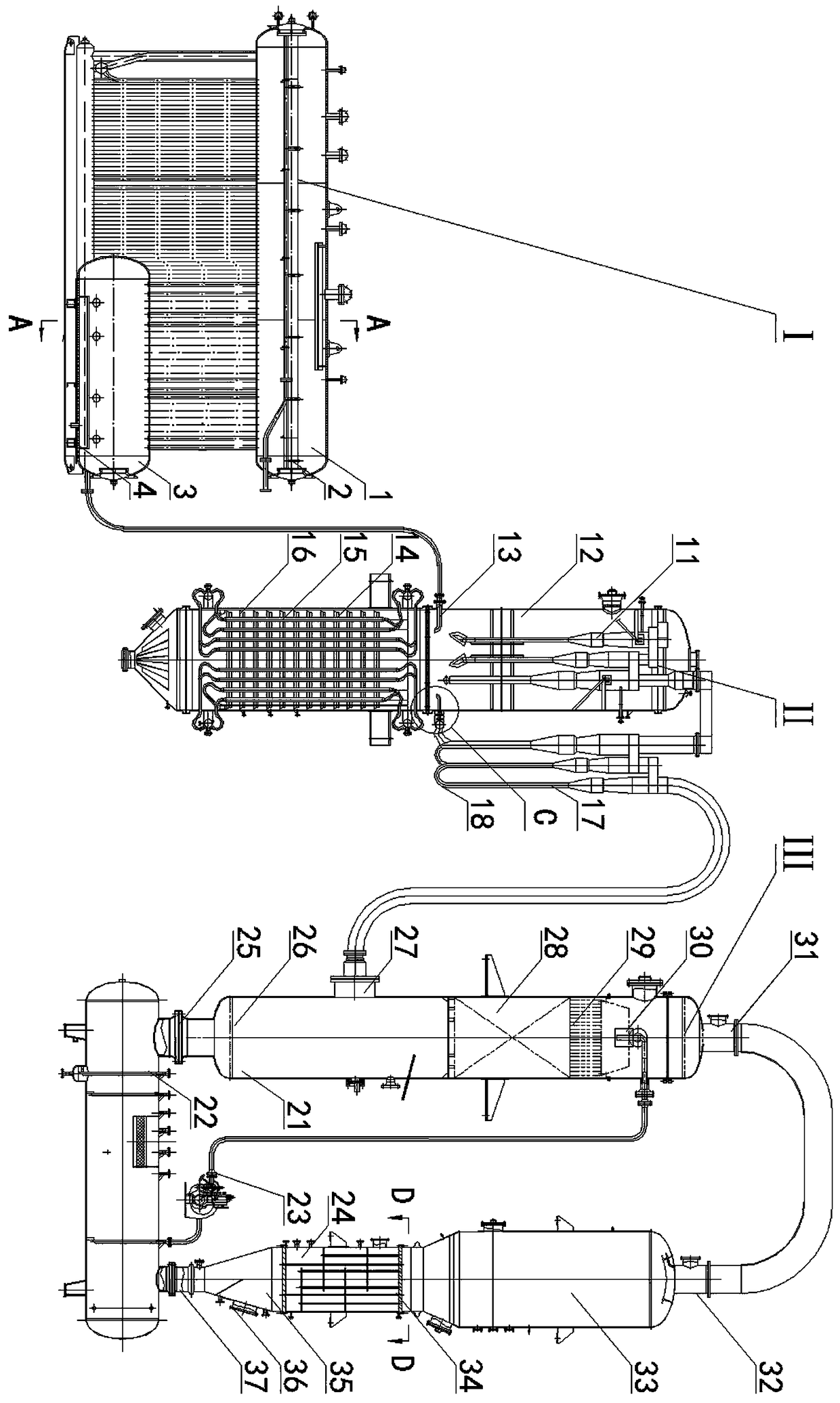

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

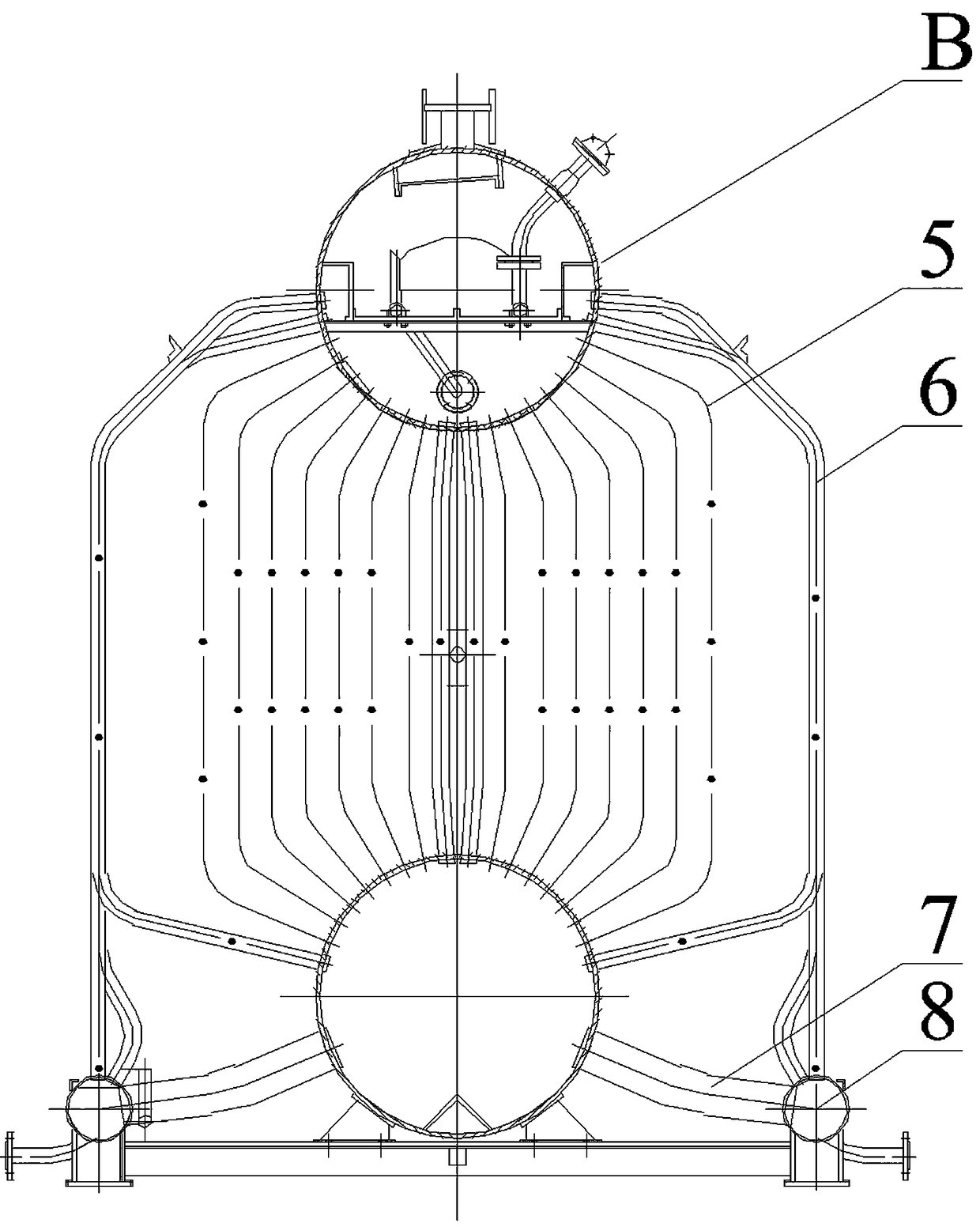

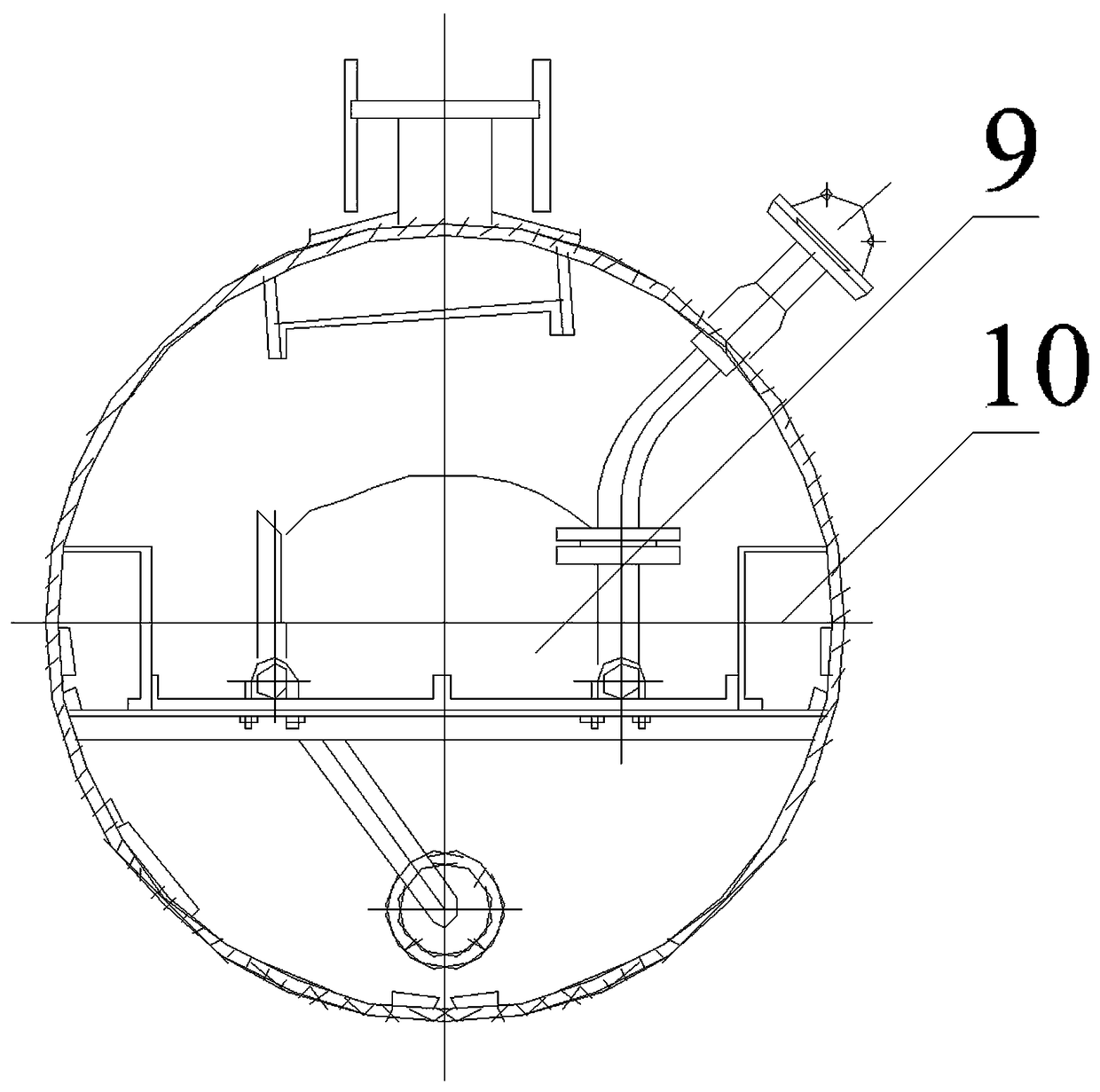

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an electronic-grade hydrogen fluoride preparation process is characterized in that it includes a transpiration cycle oxidation reaction process, a circulating fluidized bed rectification process, and a washing, absorption and condensation process.

[0034]Process 1, the transpiration cycle oxidation reaction process, the transpiration cycle reactor I maintains the normal pressure state, and the anhydrous hydrogen fluoride stored in the liquid collection tank 8 is sent to the oxidation reaction kettle 1 through the heating and gasification of the boiling exhaust pipe 6, and the heating temperature is 30~ 31°C, because the hydrogen fluoride in the boiling exhaust pipe 6 is in a boiling state after being vaporized, the bubbles rise to form a gas-liquid mixed flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com