Graphene oxide dispersion carbon nanotube solution and preparation method thereof

A technology of carbon nanotubes and graphene, which is applied in the field of graphene oxide dispersed carbon nanotube solution and its preparation, can solve the problems of limited mass fraction of carbon nanotubes, achieve poor dispersion effect, avoid damage, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare pure carbon nanotube alcohol solution, the steps are as follows:

[0027] 1) Weigh 20mg of carbon nanotubes into a beaker, and add alcohol to a total volume of 100ml to obtain a suspension of carbon nanotubes;

[0028] 2) Ultrasonic dispersion of the suspension of carbon nanotubes for 10 min using an ultrasonic stirrer to obtain a suspension of agglomerated carbon nanotubes after ultrasound.

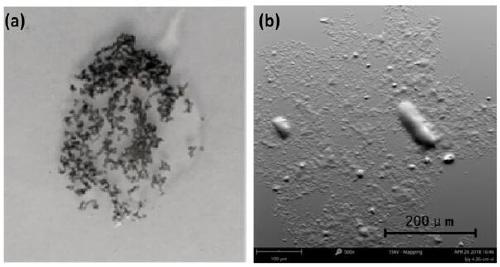

[0029] The pure carbon nanotube alcohol solution of the present embodiment is dropped on the silicon wafer and left to stand for 3 minutes, and the macroscopic appearance is as follows: figure 1 As shown in (a), the SEM microscopic appearance after dilution is as follows figure 1 As shown in (b): the carbon nanotubes show obvious aggregation phenomenon in the alcohol solution, and the microstructure shows that the carbon nanotubes are agglomerated together and distributed in flocculent form, and the morphology of a single carbon nanotube cannot be distinguished.

[0030]...

Embodiment 2

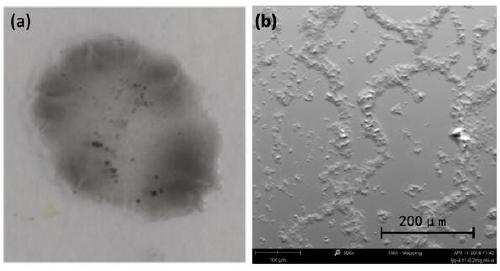

[0032] The steps of preparing the first graphene oxide dispersed carbon nanotube solution are as follows:

[0033] 1) 1g graphite powder (>325 mesh) and 12.75g CrO 3 Add it to a beaker, slowly add 10.5ml HCl (37.5wt.%), stir in a fume hood at room temperature for 2 hours, wash the product with deionized water until it is colorless, and then dry it in a vacuum oven at 60°C for 12 hours to obtain a graphite intercalation compound;

[0034] 2) Immerse the graphite intercalation compound in 30% H in a large beaker 2 o 2 After 20h in the solution 60ml, wash 3 times to obtain chemically expanded graphite;

[0035] 3) Immerse chemically expanded graphite into 200ml 98% H 2 SO 4 Remove intercalated water for 10 minutes, and filter to remove excess sulfuric acid to obtain dehydrated expanded graphite;

[0036] 4) Dissolve 120ml H in an ice-water bath 2 SO 4 , 13.3ml H 3 PO 4 Mix and stir with dehydrated expanded graphite, and add 6g KMnO within 30min 4 , remove the ice-water...

Embodiment 3

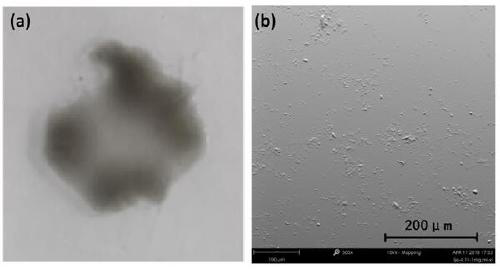

[0043] The steps of preparing the second graphene oxide dispersed carbon nanotube solution are as follows:

[0044] 1) 1g graphite powder (>325 mesh) and 12.75g CrO 3Add it to a beaker, slowly add 10.5ml HCl (37.5wt.%), stir in a fume hood at room temperature for 2 hours, wash the product with deionized water until it is colorless, and then dry it in a vacuum oven at 60°C for 12 hours to obtain a graphite intercalation compound;

[0045] 2) Immerse the graphite intercalation compound in 30% H in a large beaker 2 o 2 After 20h in the solution 60ml, wash 3 times to obtain chemically expanded graphite;

[0046] 3) Immerse chemically expanded graphite into 200ml 98%H 2 SO 4 Remove intercalated water for 10 minutes, and filter to remove excess sulfuric acid to obtain dehydrated expanded graphite;

[0047] 4) Dissolve 120ml H in an ice-water bath 2 SO 4 , 13.3ml H 3 PO 4 Mix and stir with dehydrated expanded graphite, and add 6g KMnO within 30min 4 , remove the ice-water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com