Refining method and production system of sodium benzoate

A technology of sodium benzoate and purification method, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems such as inability to guarantee the purity and clarity of sodium benzoate, no refined sodium benzoate, decomposition of sodium benzoate, etc. Instability and the effect of low clarity, improved clarity and stability, stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

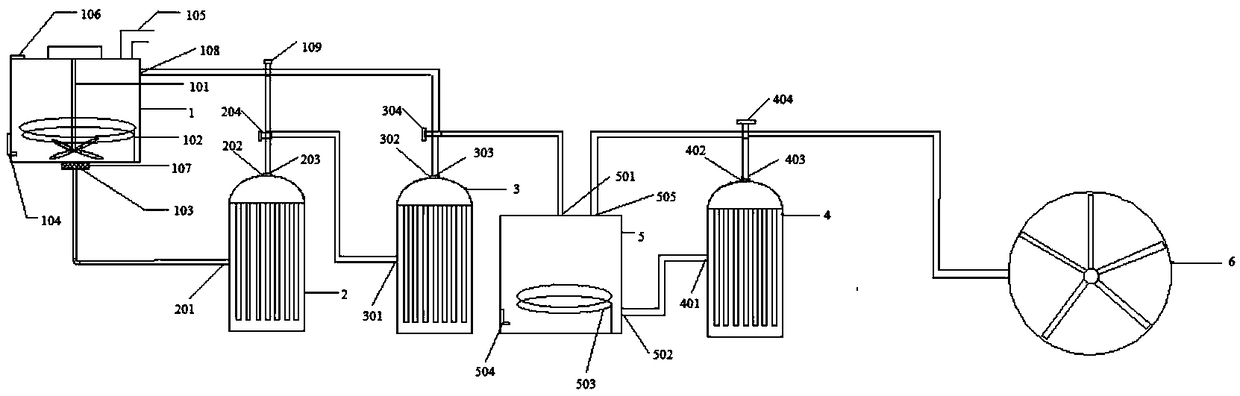

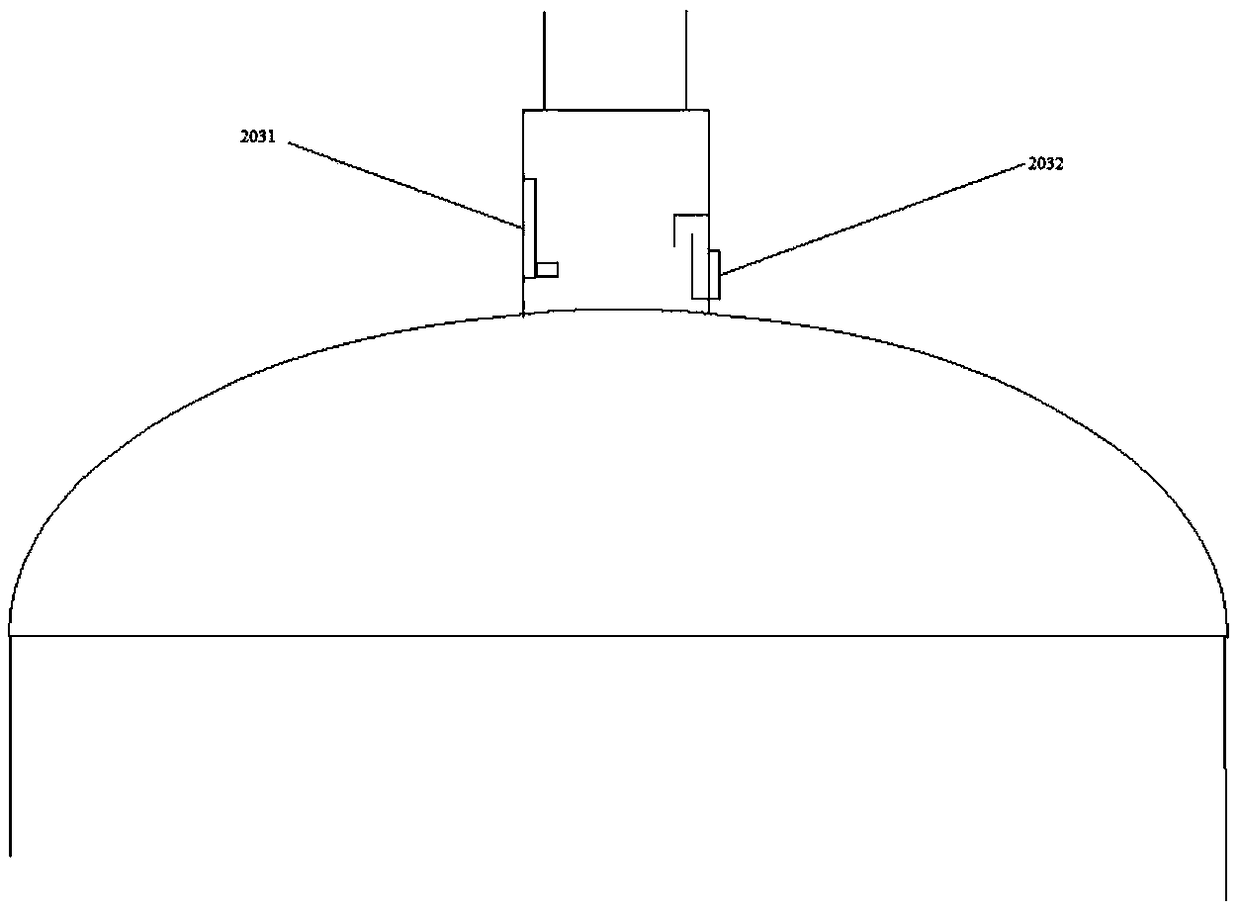

[0039] The present embodiment of the production system of the present invention provides a refined production system of pharmaceutical grade sodium benzoate, comprising a dissolution tank 1, a filter one 2, a filter two 3, a filter three 4 and a drier 6; the drier 6 can adopt a scraper Plate dryer or drying machine. Described dissolving tank 1 is provided with stirring device 101 and heating device 102; Described dissolving tank 1 is provided with water inlet 105, feed port 106, discharge port 107 and return material port 108, and the discharge port 107 of dissolving tank 1 is provided with Filter material 103, described filter material 103 preferably adopts non-woven fabric; Described filter one 2, filter two 3, filter three 4 are respectively provided with feed inlet 201,301,401 and discharge outlet 202,302 , 402; the dissolving tank 1 is provided with the inlet 201 of pipeline connection filter one 2, the outlet 202 of filter one 2 connects the inlet 301 of filter two 3, th...

Embodiment 2

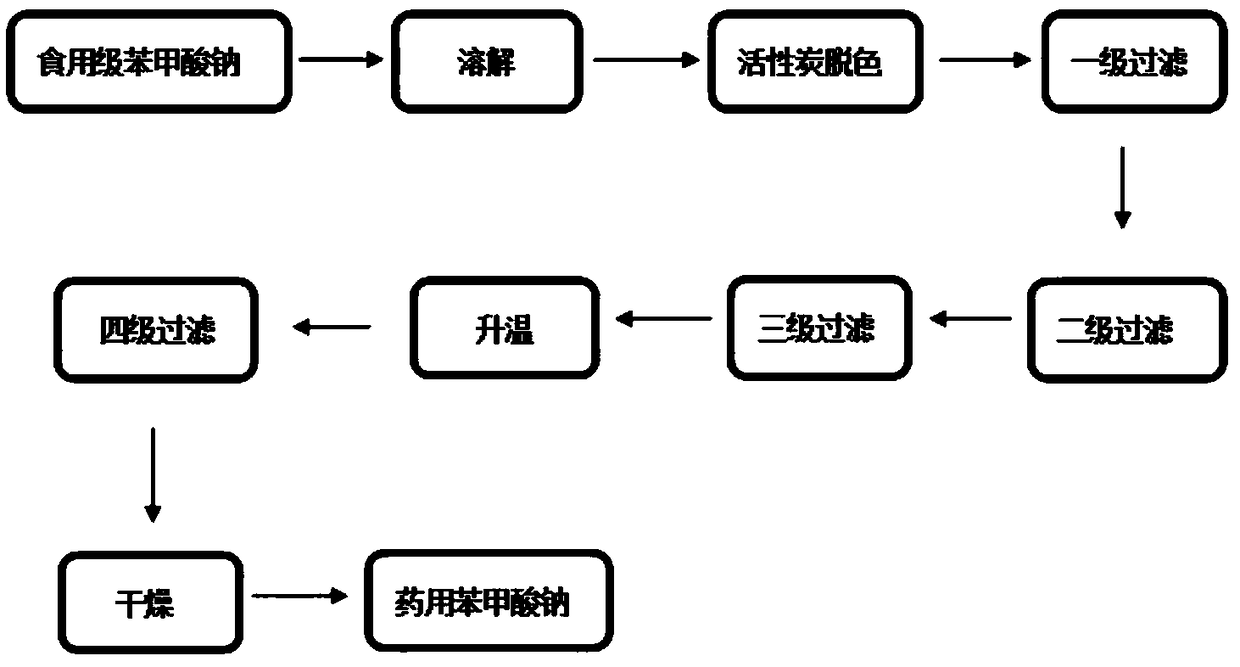

[0052] Based on the production system described in embodiment 1, the refining method of sodium benzoate of the present invention realizes as follows: open the feed inlet 106 of dissolving tank 1, sodium benzoate is dropped in dissolving tank 1, inject a certain amount of water by water inlet 105, Turn on the stirring device 101, raise the temperature of the liquid through the heating conduit 102, put activated carbon into the dissolving tank 1, close the feed port 106 of the dissolving tank 1, and stir for a certain period of time. Open the valve at the bottom of the dissolution tank 1, the liquid in the dissolution tank 1 is filtered through the non-woven fabric 103 and enters the filter one 2, and then enters the filter two 3 from the filter one 2, and records the pH tester at the outlet of the filter two 3 The displayed pH value, the pH value of the liquid treated by the filter two 3 is qualified, the valve one 304 is controlled to make the liquid in the filter two 3 enter t...

Embodiment 3

[0054] Based on the production system described in embodiment 1, the refining method of sodium benzoate of the present invention realizes as follows: open the feed inlet 106 of dissolving tank 1, sodium benzoate is dropped in dissolving tank 1, inject a certain amount of water by water inlet 105, Turn on the stirring device 101, raise the temperature of the liquid through the heating conduit 102, put activated carbon into the dissolving tank 1, close the feed port 106 of the dissolving tank 1, and stir for a certain period of time. Open the valve at the bottom of the dissolving tank 1, the liquid in the dissolving tank 1 is filtered through the non-woven fabric 103 and enters the filter one 2, records the pH value shown by the pH tester at the outlet of the filter one 2, and the material processed by the filter one 2 If the pH value of the liquid is unqualified, control valve one 204 and valve four 109 to make the liquid in the filter one 2 return to the dissolution tank 1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com