Uio-66/polyaromatic amine composite material with core-shell structure as well as preparation method and application thereof

A uio-66, core-shell structure technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of limited application, low specific surface area of polyarylamine, etc., to improve particle dispersion and cost Low, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

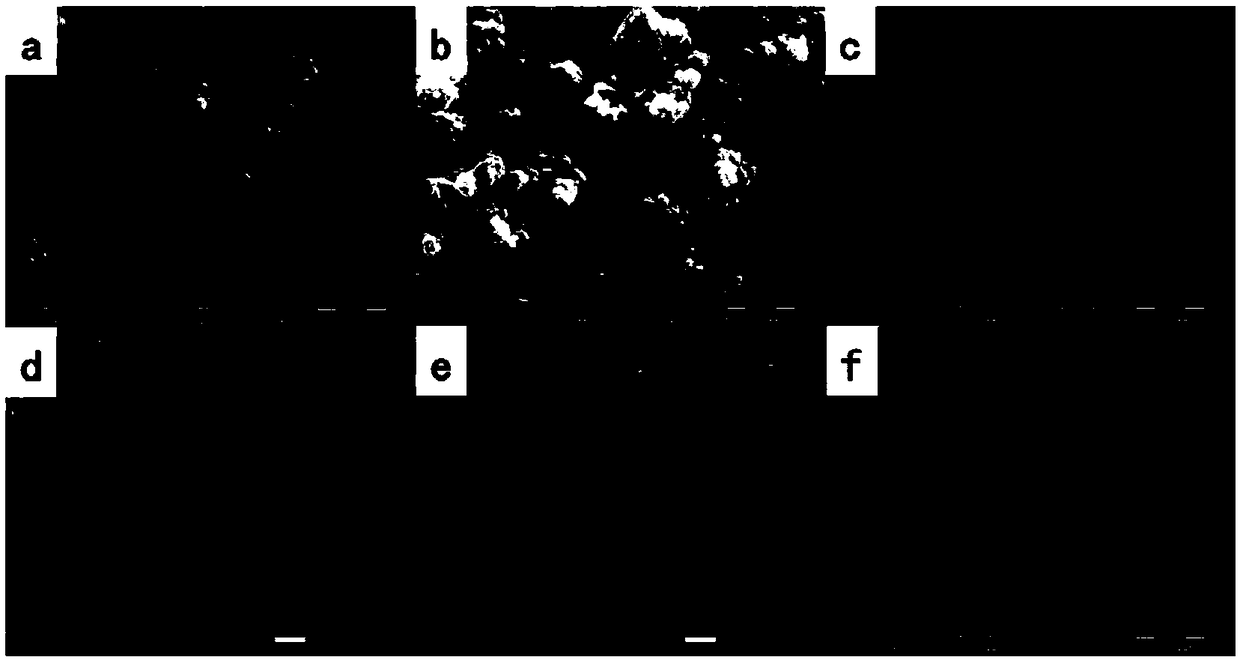

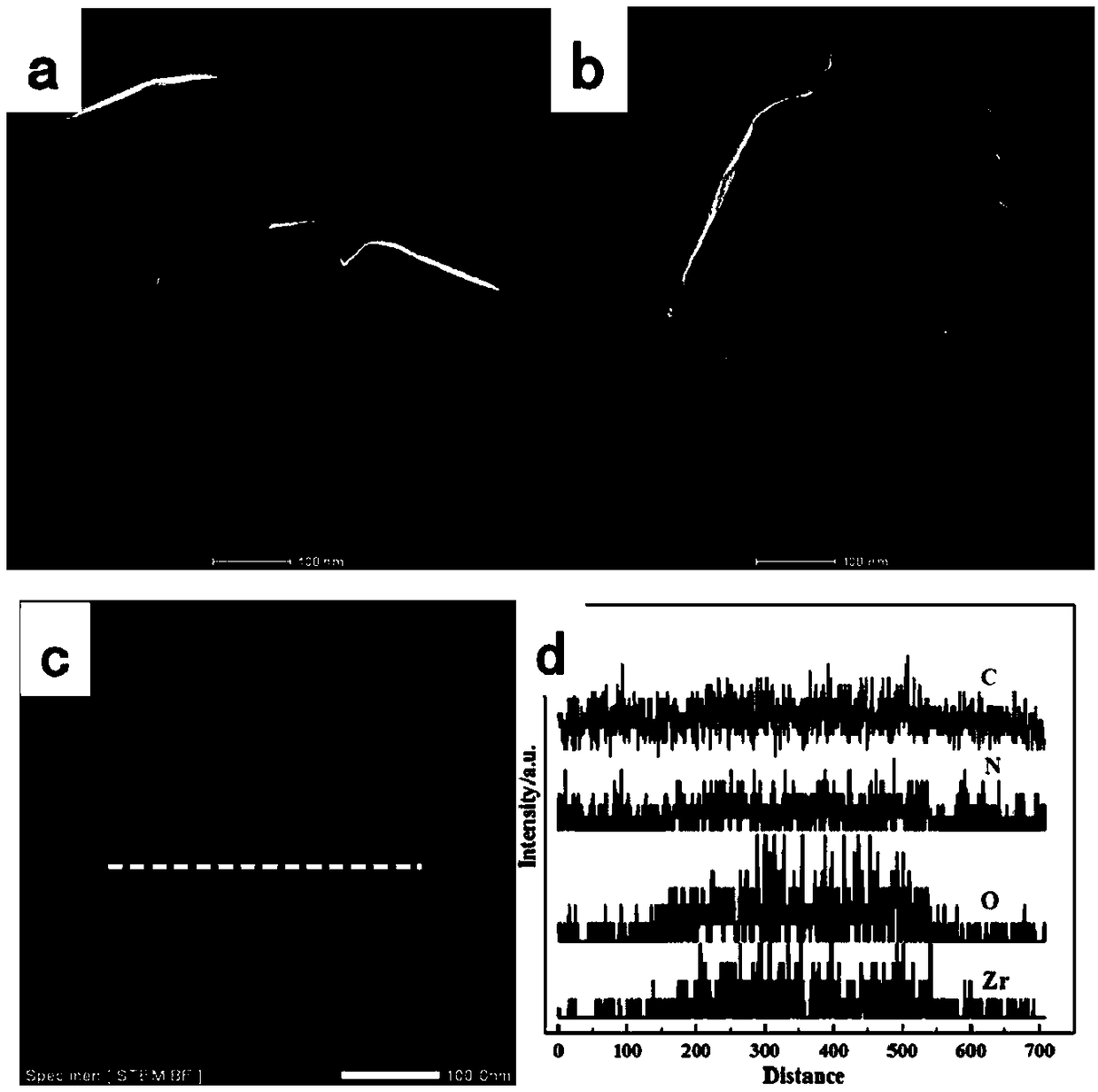

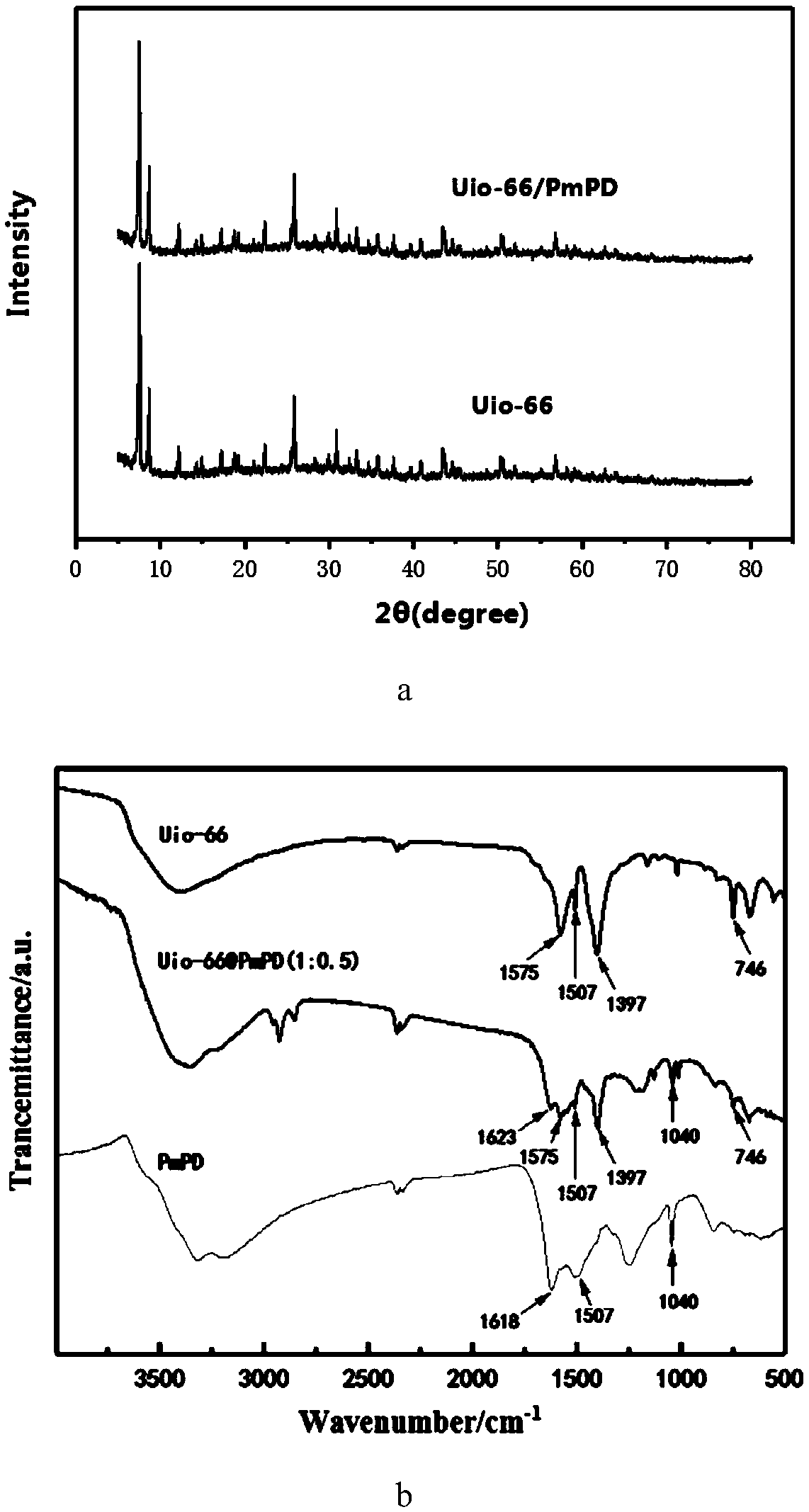

Embodiment 1

[0067] Accurately weigh 600mg Uio‐66 and add it to a 250ml round bottom flask, add 150ml distilled water to stir and ultrasonically disperse, then accurately weigh 300mg m-phenylenediamine monomer and 300mg sodium dodecylsulfonate and add it to the above flask , Stir for 16h to make it fully contact. Accurately weigh 900mg of sodium persulfate and dissolve it in 50ml of distilled water to fully dissolve it, and take 37ml for use. The sodium persulfate solution was gradually added dropwise into the round bottom flask within about 15 minutes to initiate oxidative polymerization. The above reaction was continued at room temperature (about 20° C.) for 5 h, and the reaction system gradually changed from white to dark brown. After the reaction, it was obtained by centrifugation (8000 rpm), and the residual sodium persulfate and sodium dodecylsulfonate were washed away with distilled water. The product was dried in an oven for 12 hours, and the resulting black solid powder was a na...

Embodiment 2

[0069] Accurately weigh 200mg Uio‐66 and add it to a 250ml round bottom flask, add 150ml distilled water to stir and ultrasonically disperse, then accurately weigh 600mg m-phenylenediamine monomer and 200mg sodium dodecylsulfonate and add it to the above flask , Stir for 16h to make it fully contact. Accurately weigh 1.8g of sodium persulfate and dissolve it in 50ml of distilled water to fully dissolve it, and take 37ml for use. The sodium persulfate solution was gradually added dropwise into the round bottom flask within about 15 minutes to initiate oxidative polymerization. The above reaction was continued at room temperature (about 20° C.) for 5 h, and the reaction system gradually changed from white to dark brown. After the reaction, it was obtained by centrifugation (8000 rpm), and the residual sodium persulfate and sodium dodecylsulfonate were washed away with distilled water. The product was dried in an oven for 12 hours, and the obtained black solid powder was a nano...

Embodiment 3

[0071] Accurately weigh 200mg Uio-66 and add it to a 250ml round bottom flask, add 150ml distilled water to stir and ultrasonically disperse, then accurately weigh 200mg m-phenylenediamine monomer and 200mg sodium dodecylsulfonate and add it to the above flask , Stir for 16h to make it fully contact. Accurately weigh 600mg of sodium persulfate and dissolve it in 50ml of distilled water to fully dissolve it, and take 37ml for use. The sodium persulfate solution was gradually added dropwise into the round bottom flask within about 15 minutes to initiate oxidative polymerization. The above reaction was continued at room temperature (about 20° C.) for 5 h, and the reaction system gradually changed from white to dark brown. After the reaction, it was obtained by centrifugation (8000 rpm), and the residual sodium persulfate and sodium dodecylsulfonate were washed away with distilled water. The product was dried in an oven for 12 hours, and the obtained black solid powder was a nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com