BCT/BZT-system lead-free monocrystal epitaxial multilayer energy storage film and preparation method thereof

A lead-free single crystal and thin film technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as hazards and restricted use fields, and achieve breakdown suppression, enhanced hindrance, and huge energy storage effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

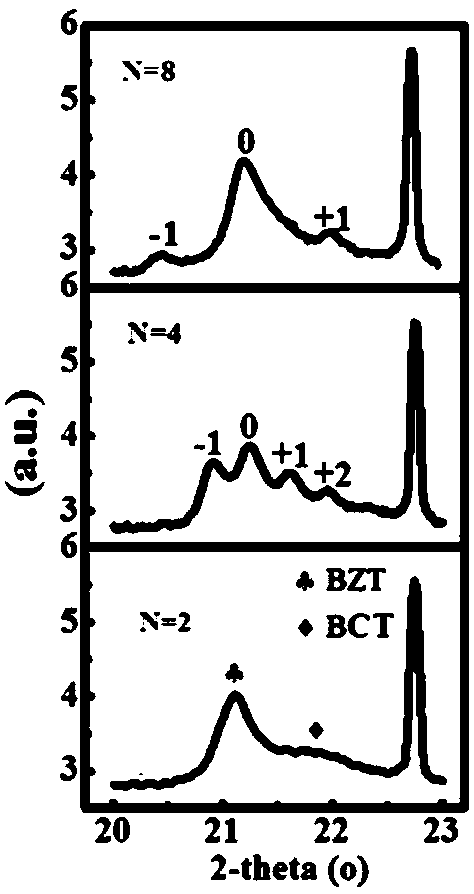

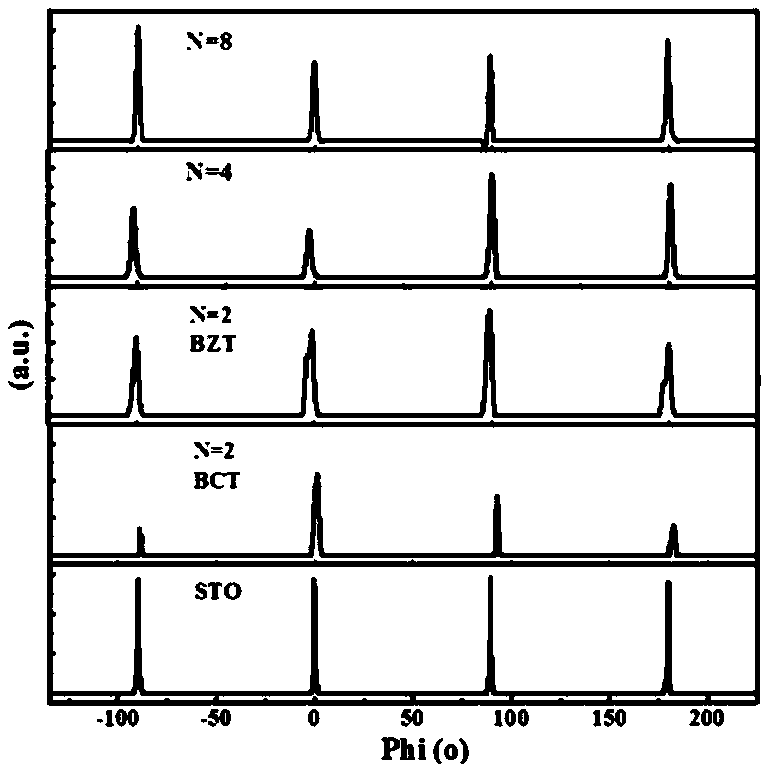

[0052] (1) First according to Ba 0.7 Ca 0.3 TiO 3 (BCT) and BaZr 0.2 Ti 0. 8O 3 The stoichiometric ratio of (BZT) weighs 4-5N grade BaCO 3 High purity powder, ZrO 2 High purity powder, TiO 2 Synthesis of BaZr from High Purity Powder 0.2 Ti 0.8 o 3 (BZT) ceramic target mixture, weigh BaCO 3 High purity powder, CaCO 3 High purity powder and TiO 2 Synthetic Ba from High Purity Powder 0.7 Ca 0.3 TiO 3 (BCT) ceramic target mixture; each target mixture is sequentially subjected to ball milling, pre-sintering, secondary ball milling, granulation, molding and sintering processes to obtain sheet-shaped BCT and BZT ceramic targets. The process parameters of ball milling and secondary ball milling are the same, specifically: the mass ratio of ball stone, mixture and alcohol is 2:1:1, the ball milling speed is 400r / min, and the ball milling time is 6h; the pre-sintering temperature is 900℃, pre-sintering The sintering time is 4h; it is formed by a tablet press, the pressur...

Embodiment 2

[0059] In the present embodiment, in step 2, the ultrasonic cleaning time is 3min; -5 mbar, when the substrate temperature is 850°C, pump the air pressure in the cavity to 10 -5 mbar; in step (5), a film with N=4 is prepared, the growth time of the single-layer BCT layer is 46min, and the thickness is 7.5nm; the growth time of the BZT layer is 126min, and the thickness is 17.5nm; it is formed after 4 cycles of staggered preparation Process film; the rest of the steps are the same as in Example 1.

Embodiment 3

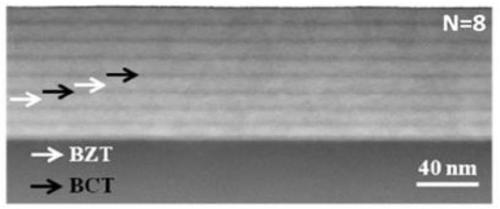

[0061] In the present embodiment, in step 2, the ultrasonic cleaning time is 4min; -4 mbar, when the substrate temperature is 850°C, pump the air pressure in the cavity to 10 -5 mbar; in step (5), the film of N=8 is prepared, the growth time of the single-layer BCT layer is 23min, and the thickness is 3.8nm; the growth time of the single-layer BZT layer is 63min, and the thickness is 8.8nm; 8 cycles of staggered preparation Afterwards, the process film is formed; the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com