Rabbit dried meat slice made of mince and method for processing rabbit dried meat slice

A processing method and technology for rabbit meat, which are applied in the directions of food ingredients as taste modifiers, food ingredients as smell modifiers, and food ingredients as taste modifiers, etc. Difficulty and difficulty in mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A processing method for minced rabbit meat, characterized in that it comprises the following steps:

[0046] (1) Deboning the whole rabbit, removing the connective tissue, and cleaning; washing with rice washing water not higher than 25°C, and then washing with water;

[0047] (2) Remove the fishy smell: remove the fishy smell from the cleaned rabbit meat; the method of removing the fishy smell is as follows:

[0048] a) Take lysozyme dry powder and dissolve it in normal temperature water, cut the rabbit meat into pieces and soak in the lysozyme solution for 10 minutes; the amount of the lysozyme is 0.5% of the total weight of the rabbit meat; the amount of normal temperature water does not exceed the rabbit meat The volume of the meat block is > 1dm 3 ;

[0049] b) Wash the above rabbit meat with clean water; put it into a pot of cold water and heat it up, keep the fire to the minimum under the premise of not extinguishing, and turn off the fire after 30 minutes;

...

Embodiment 2

[0062] The step (4) chopping and mixing process is as follows: the soybean protein isolate is put into the chopping machine, and the soybean protein isolate is added ice water for chopping Then add the marinated rabbit meat, chop and mix, and slowly add ice water until the viscosity of the rabbit meat increases, and finally form a viscous whole; add the remaining marinade and continue to chop and mix Add starch and minced pork back fat, continue chopping The addition amount of described starch is the total weight of rabbit minced meat The added amount of the pig backfat minced meat is 5% of the total weight of the rabbit minced meat. During the chopping process, the temperature of the chopping knife is strictly controlled by gradually adding ice chips, and the final temperature of the chopping is controlled at

[0063] All the other parts are the same as in Example 1.

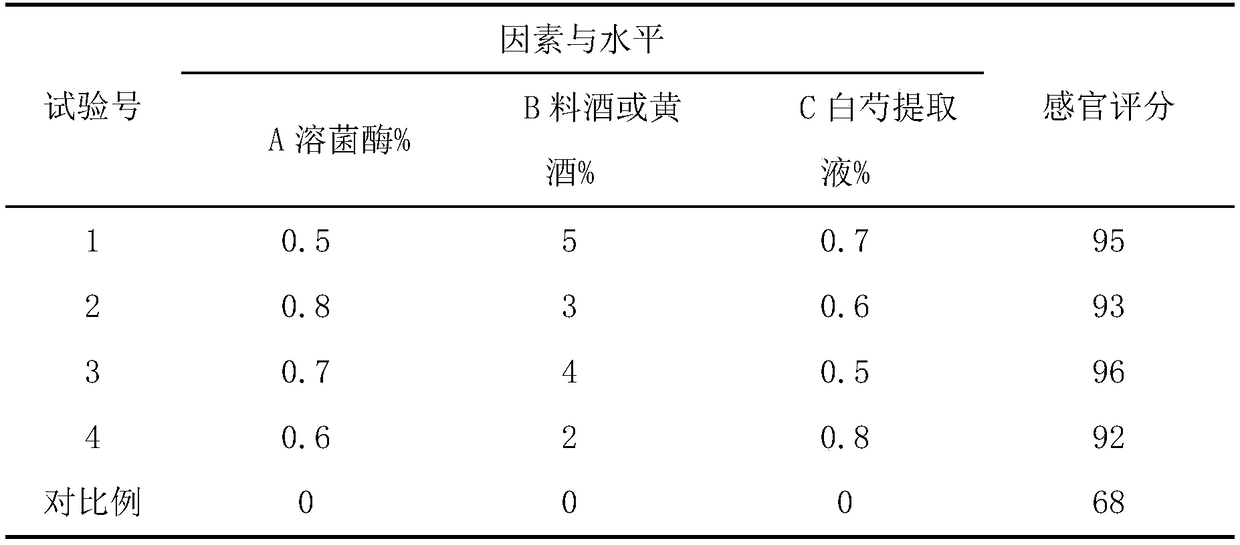

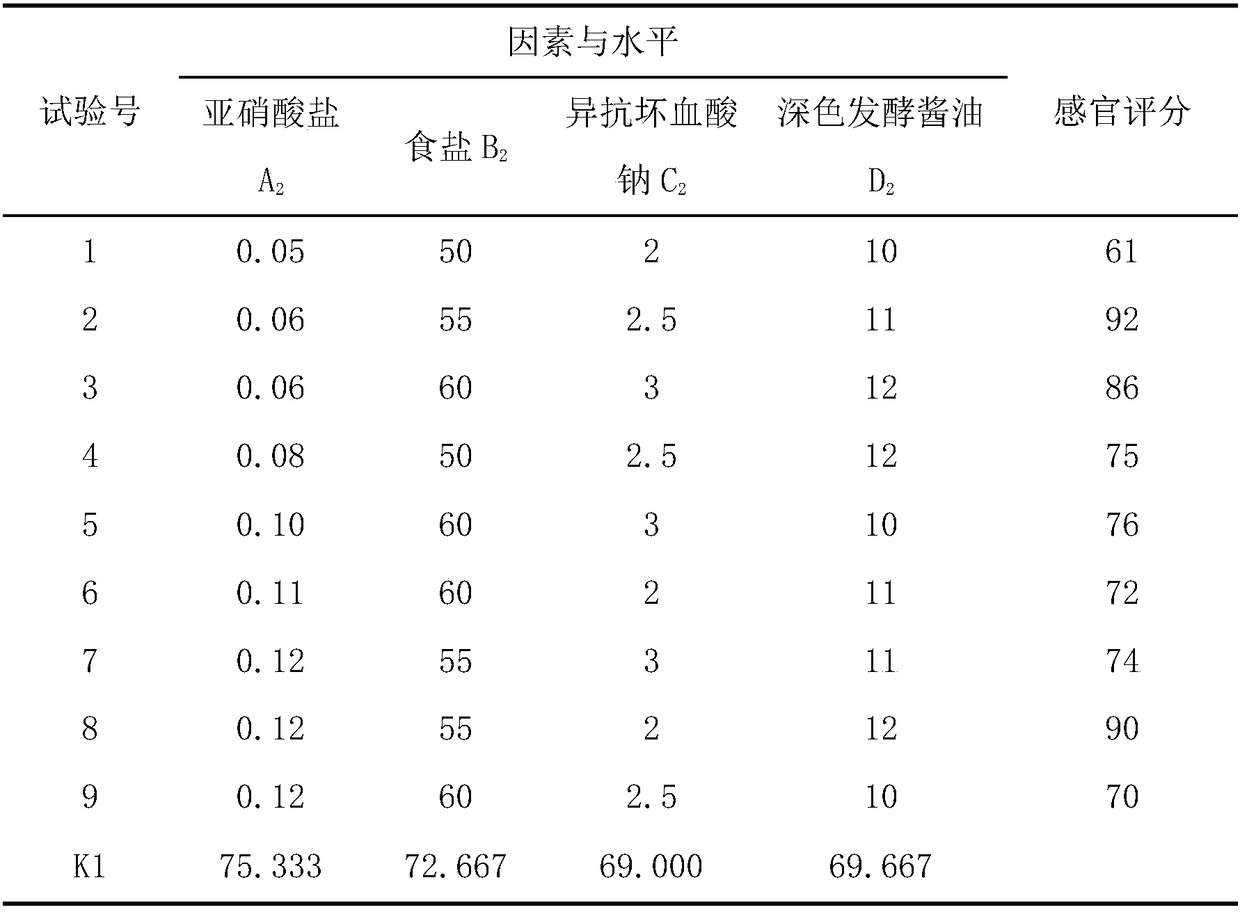

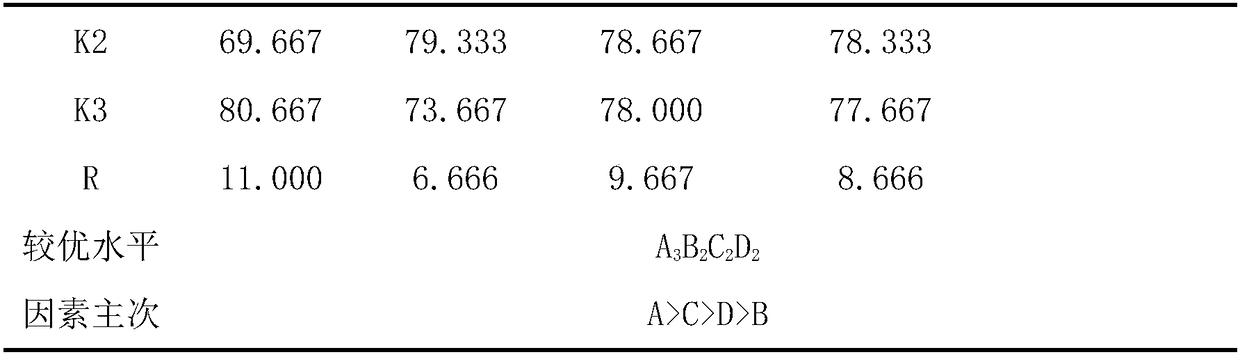

[0064] Flavor and mouthfeel tests were carried out on the rabbit jerky prepared with different c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com