Magnetic nano-fiber drug carrier and preparation method thereof

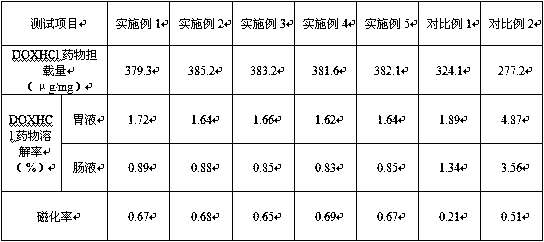

A magnetic nano-fiber technology, applied in the field of medical materials, can solve the problems of small drug loading, poor loading stability, and unsatisfactory targeted delivery and drug delivery, and achieve stable drug loading, large drug loading, and Realize the effect of drug orientation and targeted drug delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a. Disperse keratin in N,N-dimethylformamide, and obtain hollow nano-keratin fibers by electrospinning;

[0031] b, the hollow nano-keratin fiber that step a makes is immersed in FeCl 3 ·6H 2 O, FeCl 2 4H 2 O, in the aqueous solution of organosilane, obtain fiber dispersion liquid;

[0032] c. Apply a vacuum to the dispersion liquid in step b, so that the iron salt enters the pores of the hollow nano-keratin, then add hydrogen peroxide, and add dropwise an aqueous sodium hydroxide solution, so that the iron salt forms a colloid in the hollow nano-keratin;

[0033] d, filter, wash with deionized water until the pH is 7, dry in vacuum, and form silica / Fe in the pores of hollow nanokeratin fibers 3 o 4 Gel network to prepare magnetic nanofiber drug carrier.

[0034] In step b, the organosilane is tetramethylsilane;

[0035] In step a, 7 parts by weight of keratin, 93 parts by weight of N,N-dimethylformamide; in step b, 25 parts by weight of hollow nano-keratin fiber...

Embodiment 2

[0038] a. Disperse keratin in N,N-dimethylformamide, and obtain hollow nano-keratin fibers by electrospinning;

[0039] b, the hollow nano-keratin fiber that step a makes is immersed in FeCl 3 ·6H 2 O, FeCl 2 4H 2 O, in the aqueous solution of organosilane, obtain fiber dispersion liquid;

[0040]c. Apply a vacuum to the dispersion liquid in step b, so that the iron salt enters the pores of the hollow nano-keratin, then add hydrogen peroxide, and add dropwise an aqueous sodium hydroxide solution, so that the iron salt forms a colloid in the hollow nano-keratin;

[0041] d, filter, wash with deionized water until the pH is 7, dry in vacuum, and form silica / Fe in the pores of hollow nanokeratin fibers 3 o 4 Gel network to prepare magnetic nanofiber drug carrier.

[0042] In step b, organosilane is methyl silicone oil;

[0043] In step a, 5 parts by weight of keratin, 95 parts by weight of N,N-dimethylformamide; in step b, 20 parts by weight of hollow nano-keratin fibers, ...

Embodiment 3

[0046] a. Disperse keratin in N,N-dimethylformamide, and obtain hollow nano-keratin fibers by electrospinning;

[0047] b, the hollow nano-keratin fiber that step a makes is immersed in FeCl 3 ·6H 2 O, FeCl 2 4H 2 O, in the aqueous solution of organosilane, obtain fiber dispersion liquid;

[0048] c. Apply a vacuum to the dispersion liquid in step b, so that the iron salt enters the pores of the hollow nano-keratin, then add hydrogen peroxide, and add dropwise an aqueous sodium hydroxide solution, so that the iron salt forms a colloid in the hollow nano-keratin;

[0049] d, filter, wash with deionized water until the pH is 7, dry in vacuum, and form silica / Fe in the pores of hollow nanokeratin fibers 3 o 4 Gel network to prepare magnetic nanofiber drug carrier.

[0050] In step b, the organosilane is vinylsilane;

[0051] In step a, 8 parts by weight of keratin, 92 parts by weight of N,N-dimethylformamide; in step b, 30 parts by weight of hollow nano-keratin fibers, 92 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com