A method for preparing multifunctional sodium alginate scaffolds embedded with drug-loaded microspheres using 3D printing technology based on in-situ emulsification

A sodium alginate, 3D printing technology, applied in pharmaceutical formulations, microcapsules, drug delivery and other directions, can solve the problems of lack of antibacterial and anti-inflammatory stents, poor mechanical properties of stents, low osteogenic activity, etc., to avoid toxic side effects, mechanical Performance enhancement, the effect of enhancing osteogenic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of amino-modified polylactic acid: Dissolve poly-L-lactic acid particles in 1,4-dioxane solvent in a 60°C water bath to prepare a homogeneous solution with a concentration of 1 wt%. A 1.2 wt% ethylenediamine aqueous solution was added to the phase solution, reacted for 30 min, cooled to room temperature, and then placed in a freeze dryer at -80 °C to freeze-dry to obtain aminated polylactic acid.

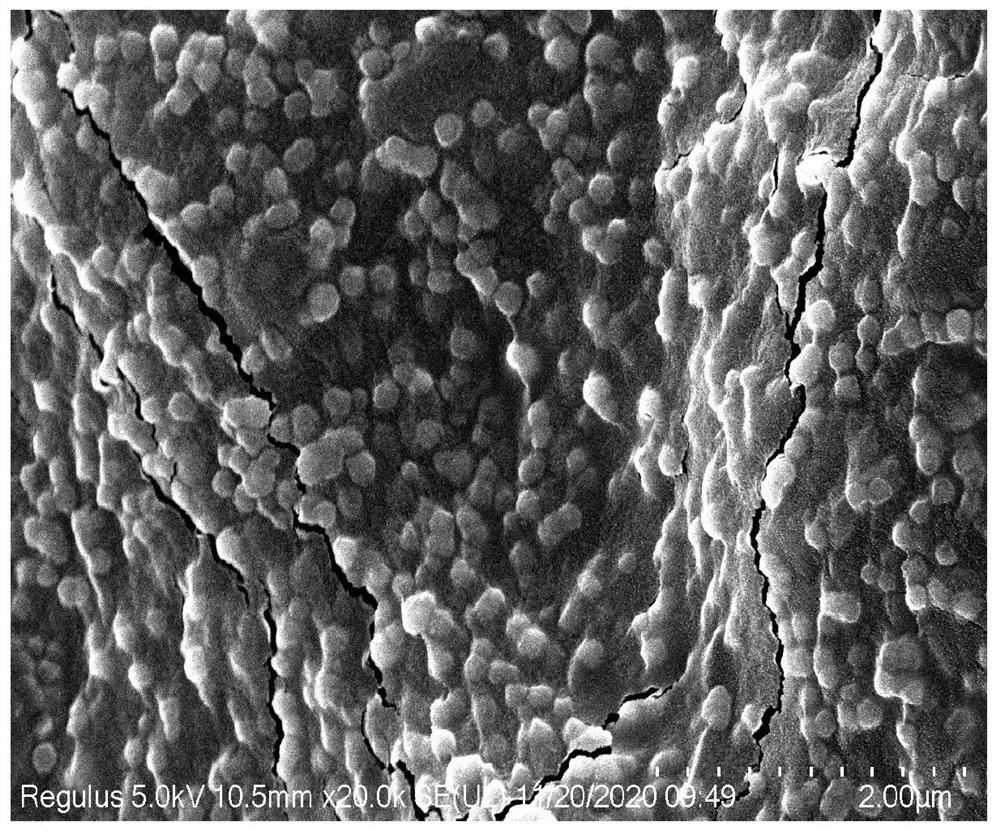

[0022] 2) Preparation of printing paste: Weigh a certain amount of lecithin and sodium alginate and dissolve them in 4 wt% ethanol aqueous solution to obtain a lecithin-dissolved sodium alginate solution, and lecithin-dissolved sodium alginate solution The concentration of lecithin was 1 wt%. Dissolving the amino-modified polylactic acid and ibuprofen drug prepared in step 1) in 1,4-dioxane solvent to obtain a modified polylactic acid solution with ibuprofen drug dissolved, wherein the concentration of the modified polylactic acid is is 2 wt%, and the concentr...

Embodiment 2

[0025] 1) Preparation of amino-modified polylactic acid: Dissolve poly-L-lactic acid particles in 1,4-dioxane solvent in a 60°C water bath to prepare a homogeneous solution with a concentration of 1 wt%. A 1.2 wt% ethylenediamine aqueous solution was added to the phase solution, reacted for 30 min, cooled to room temperature, and then placed in a freeze dryer at -80 °C to freeze-dry to obtain aminated polylactic acid.

[0026] 2) Preparation of printing paste: Weigh a certain amount of lecithin and sodium alginate and dissolve them in 4 wt% ethanol aqueous solution to obtain a lecithin-dissolved sodium alginate solution, and lecithin-dissolved sodium alginate solution The concentration of lecithin was 3 wt%. Dissolving the amino-modified polylactic acid and minocycline drug prepared in step 1) in 1,4-dioxane solvent to obtain a modified polylactic acid solution in which minocycline drug is dissolved, wherein the modified polylactic acid The concentration of lactic acid was 3 ...

Embodiment 3

[0029] 1) Preparation of amino-modified polylactic acid: Dissolve poly-L-lactic acid particles in 1,4-dioxane solvent in a 60°C water bath to prepare a homogeneous solution with a concentration of 1 wt%. A 1.2 wt% ethylenediamine aqueous solution was added to the phase solution, reacted for 30 min, cooled to room temperature, and then placed in a freeze dryer at -80 °C to freeze-dry to obtain aminated polylactic acid.

[0030] 2) Preparation of printing paste: Weigh a certain amount of lecithin and sodium alginate and dissolve them in 4 wt% ethanol aqueous solution to obtain a lecithin-dissolved sodium alginate solution, and lecithin-dissolved sodium alginate solution The concentration of lecithin is 2 wt%. Dissolving the amino-modified polylactic acid, loxoprofen sodium and vancomycin drug prepared in step 1) in 1,4-dioxane solvent to obtain loxoprofen sodium and vancomycin drug dissolved Modified polylactic acid solution, wherein the concentration of modified polylactic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com