A kind of composite photocatalyst and its preparation method and application

A catalyst and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of complex preparation methods and poor dispersibility, and achieve the advantages of simple preparation methods, easy film formation, and solutions to agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

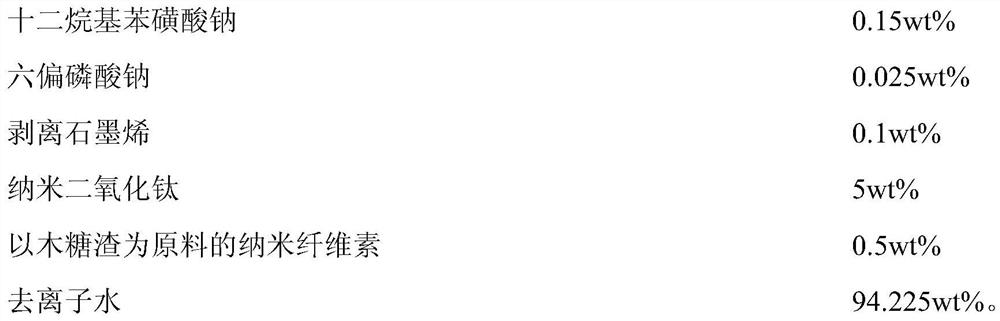

[0090] A composite photocatalyst comprising:

[0091]

[0092] The preparation method of described composite photocatalyst comprises the steps:

[0093] Add 1.5g of sodium dodecylbenzenesulfonate and 0.25g of sodium hexametaphosphate to the aqueous dispersion of 50g of exfoliated graphene and the aqueous solution of 500g of nano-titanium dioxide, after stirring, ultrasonic and high-pressure homogenizer treatment , to obtain graphene aqueous dispersion A and TiO 2 The pre-dispersion B; then slowly add the dispersion A to the dispersion B, after stirring, ultrasonic and high-pressure homogenizer to obtain the mixed dispersion C; finally add the weighed 250g 2wt% nanofiber Aqueous plain solution, constant volume 1kg, after stirring, ultrasonic and ball milling treatment at room temperature, and finally get off-white homogeneous TiO 2 Aqueous dispersion of graphene / nanocellulose ternary composite catalyst.

Embodiment 2

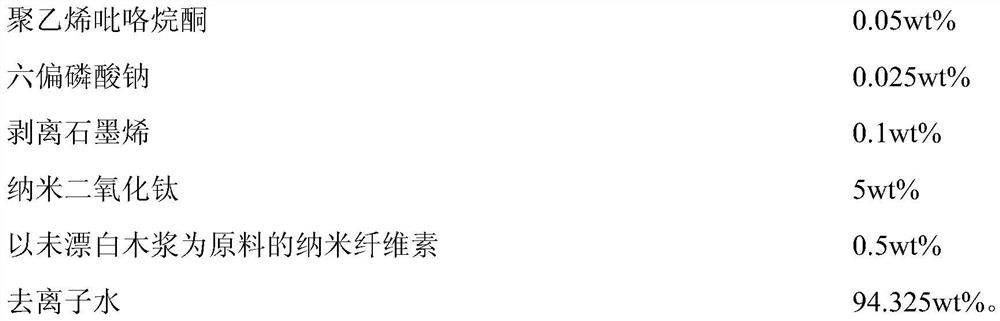

[0095] A composite photocatalyst comprising:

[0096]

[0097] The preparation method of described composite photocatalyst comprises the steps:

[0098] 0.5g of polyvinylpyrrolidone and 0.25g of sodium hexametaphosphate were added to the aqueous dispersion of 50g of exfoliated graphene and the aqueous solution of 500g of nano-titanium dioxide, and after stirring, ultrasonic and high-pressure homogenizer treatment, graphene was obtained respectively. Aqueous dispersion A and TiO 2 The pre-dispersion B; then slowly add the dispersion A to the dispersion B, after stirring, ultrasonic and high-pressure homogenizer to obtain the mixed dispersion C; finally add the weighed 250g 2wt% nanofiber Aqueous plain solution, constant volume 1kg, after stirring, ultrasonic and ball milling treatment at room temperature, and finally get off-white homogeneous TiO 2 Aqueous dispersion of graphene / nanocellulose ternary composite catalyst.

Embodiment 3

[0100] A composite photocatalyst comprising:

[0101]

[0102] The preparation method of described composite photocatalyst comprises the steps:

[0103] 0.83g of polyvinylpyrrolidone and 0.5g of sodium hexametaphosphate were added to the aqueous dispersion of 83g of exfoliated graphene and the aqueous solution of 334g of nano-titanium dioxide, and after stirring, ultrasonic and high-pressure homogenizer treatment, graphene was obtained respectively. Aqueous dispersion A and TiO 2 The pre-dispersion B; then slowly add the dispersion A to the dispersion B, after stirring, ultrasonic and high-pressure homogenizer to obtain the mixed dispersion C; finally add the weighed 400g 2.5wt% nano Cellulose aqueous solution, constant volume 1kg, after stirring, ultrasonication and ball milling at room temperature, finally get off-white uniform TiO 2 Aqueous dispersion of graphene / nanocellulose ternary composite catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com