Method for preparing germanium selenide two-dimensional materials on basis of solvent thermal intercalation processes

A two-dimensional material, the technology of germanium selenide, applied in the field of preparation of two-dimensional germanium selenide material, can solve the problems that the lateral size and thickness cannot be taken into account at the same time, and the peeling effect is not ideal, and the preparation method is simple and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 79 mg of selenium and 72.6 mg of germanium powder and place them in a quartz glass tube for vacuum packaging, slowly heat to 600 ° C, keep warm for 12 hours, and naturally cool to room temperature to obtain a germanium selenide body material;

[0025] (2) Put the germanium selenide body material obtained in step (1) into a reaction kettle, add ethanol, put it into a muffle furnace, heat up to 150° C., and keep it warm for 24 hours;

[0026] (3) putting the germanium selenide dispersion after solvothermal in step (2) into a cell pulverizer, and performing ultrasonic treatment, the ultrasonic power is 50W, and the ultrasonic time is 20h;

[0027] (4) Centrifuge the germanium selenide dispersion after the ultrasonic wave, the centrifugal speed is 8000r / min, and the centrifugation time is 5min to obtain a gray-black supernatant;

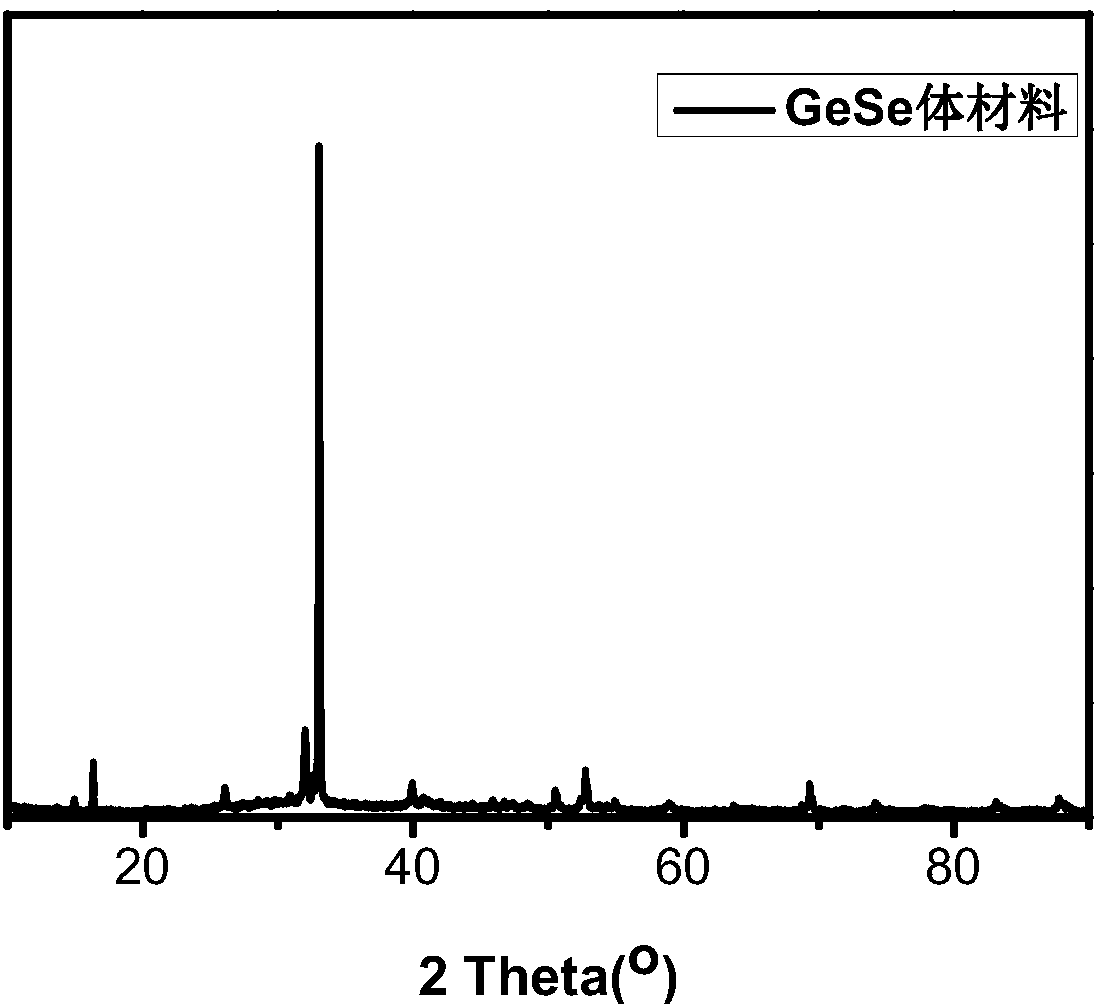

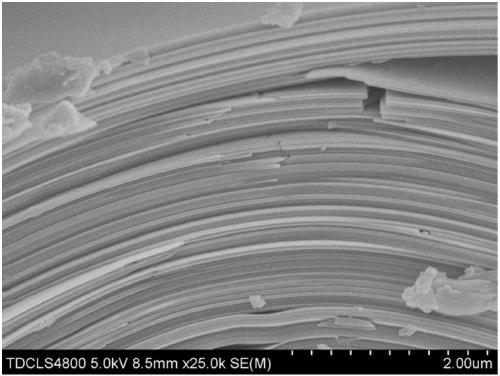

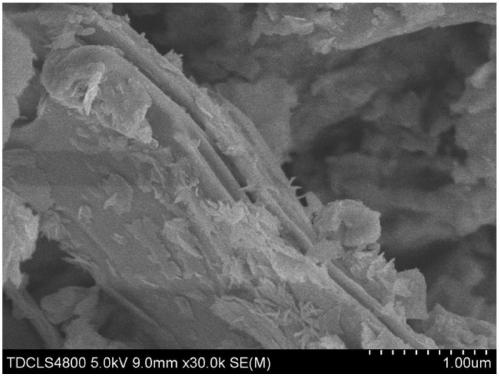

[0028] The gray solid obtained in step (1) is characterized by X-ray diffraction and scanning electron microscopy, and figure 1 Compar...

Embodiment 2

[0030] (1) Weigh 79 mg of selenium and 72.6 mg of germanium powder and place them in a quartz glass tube for vacuum packaging, slowly heat to 900 ° C, keep warm for 48 hours, and naturally cool to room temperature to obtain a germanium selenide body material;

[0031] (2) Put the germanium selenide body material obtained in step (1) into a reaction kettle, add methanol, put it into a muffle furnace, heat up to 100° C., and keep it warm for 48 hours;

[0032] (3) Put the germanium selenide dispersion liquid after solvothermal in step (2) into the cell pulverizer, carry out ultrasonic treatment, the power of ultrasonic is 150W, and ultrasonic time is 10h;

[0033] (4) Centrifuge the germanium selenide dispersion after the ultrasonic wave, the centrifugal speed is 5000r / min, and the centrifugation time is 20min to obtain a gray-black supernatant;

[0034] (5) X-ray diffraction and scanning electron microscope characterization are carried out to the gray solid obtained in step (1)...

Embodiment 3

[0036] (1) Weigh 79 mg of selenium and 72.6 mg of germanium powder and place them in a quartz glass tube for vacuum packaging, slowly heat to 750 ° C, keep warm for 72 hours, and naturally cool to room temperature to obtain a germanium selenide body material;

[0037] (2) Put the germanium selenide body material obtained in step (1) into a reaction kettle, add dimethylformamide, put it into a muffle furnace, heat up to 200° C., keep it warm for 8 hours, and perform scanning electron microscope characterization;

[0038] (3) Put the germanium selenide dispersion after solvothermal in step (2) into a cell pulverizer, carry out ultrasonic treatment, the ultrasonic power is 300W, and the ultrasonic time is 2h;

[0039] (4) Centrifuge the germanium selenide dispersion after the ultrasonic wave, the centrifugal speed is 1000r / min, and the centrifugation time is 60min to obtain a gray-black supernatant;

[0040] (5) X-ray diffraction and scanning electron microscope characterization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com