Method for preparing mixed ester rich in OPO structural lipids

A technology of mixed ester and structural fat, applied in the field of preparation of mixed ester, can solve the problems of less source of oil and fat raw materials, increased production process and high cost, and achieve the effect of shortening process flow and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

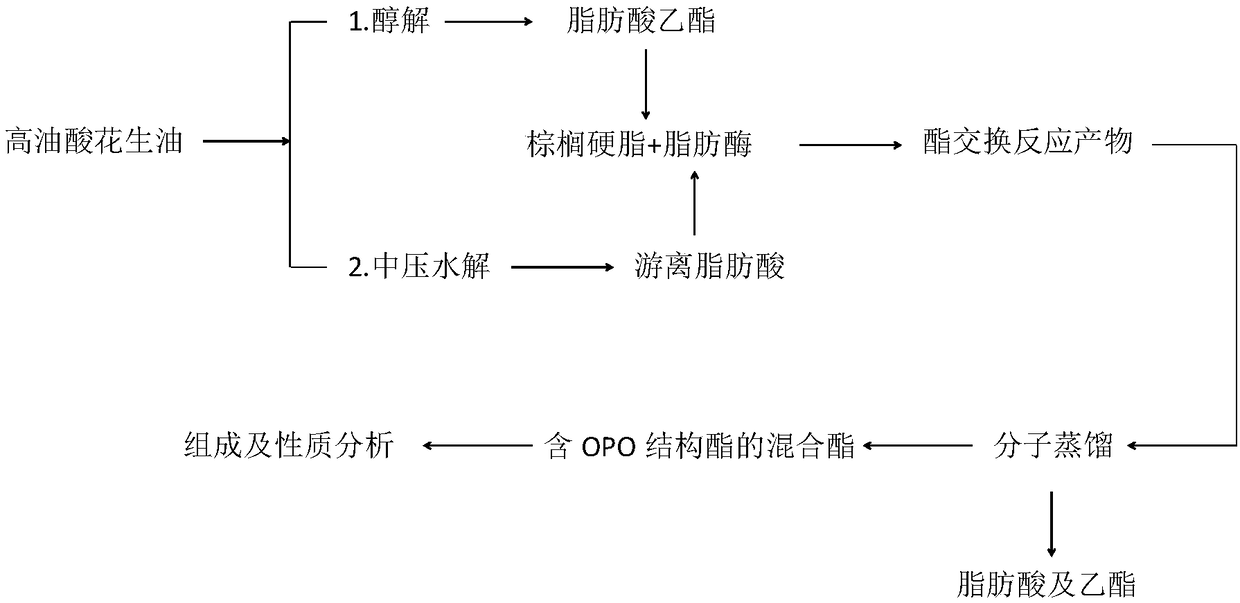

[0032] The invention provides a kind of preparation method of the mixed ester that is rich in OPO structure fat, comprises the following steps:

[0033] 1) The high oleic peanut oil is subjected to alcoholysis reaction or medium pressure hydrolysis reaction to obtain a reaction product; the oleic acid content of the high oleic peanut oil is ≥ 70%; the reaction product of the alcoholysis reaction is fatty acid ethyl ester, and the middle The reaction product of pressure hydrolysis reaction is fatty acid;

[0034] 2) The reaction product obtained in the step 1), palm stearin and Sn-1, 3-position-specific lipase are mixed and then transesterified to obtain mixed esters rich in OPO structural lipids.

[0035] In the present invention, the high oleic peanut oil undergoes alcoholysis reaction or medium pressure hydrolysis reaction to obtain a reaction product; the oleic acid content of the high oleic peanut oil is ≥70%; the reaction product of the alcoholysis reaction is fatty acid ...

Embodiment 1

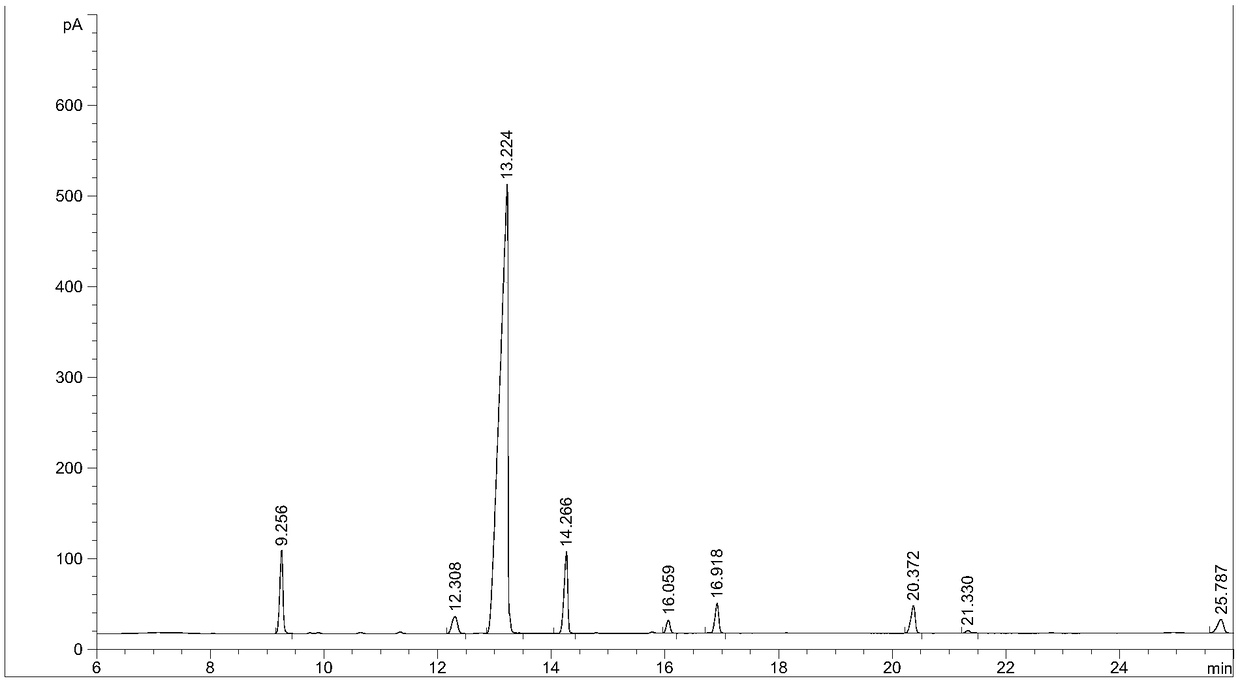

[0064] 1) Weigh 2.16g NaOH into a 1000mL three-neck flask, add 160g absolute ethanol and 432g high oleic peanut oil, and stir magnetically in an oil bath at 75°C for 1.5h under nitrogen protection. After completion of the reaction, cool to room temperature, remove excess ethanol by rotary evaporation under reduced pressure, then pour into a separatory funnel and let stand to separate layers, separate the sodium hydroxide, glycerin and soap in the lower layer, wash with 50 ° C distilled water until neutral, reduce The reaction product fatty acid ethyl ester was obtained by rotary steaming and dehydration, which was packed into a 500mL sample bottle, filled with nitrogen gas for protection and placed in a refrigerator for later use.

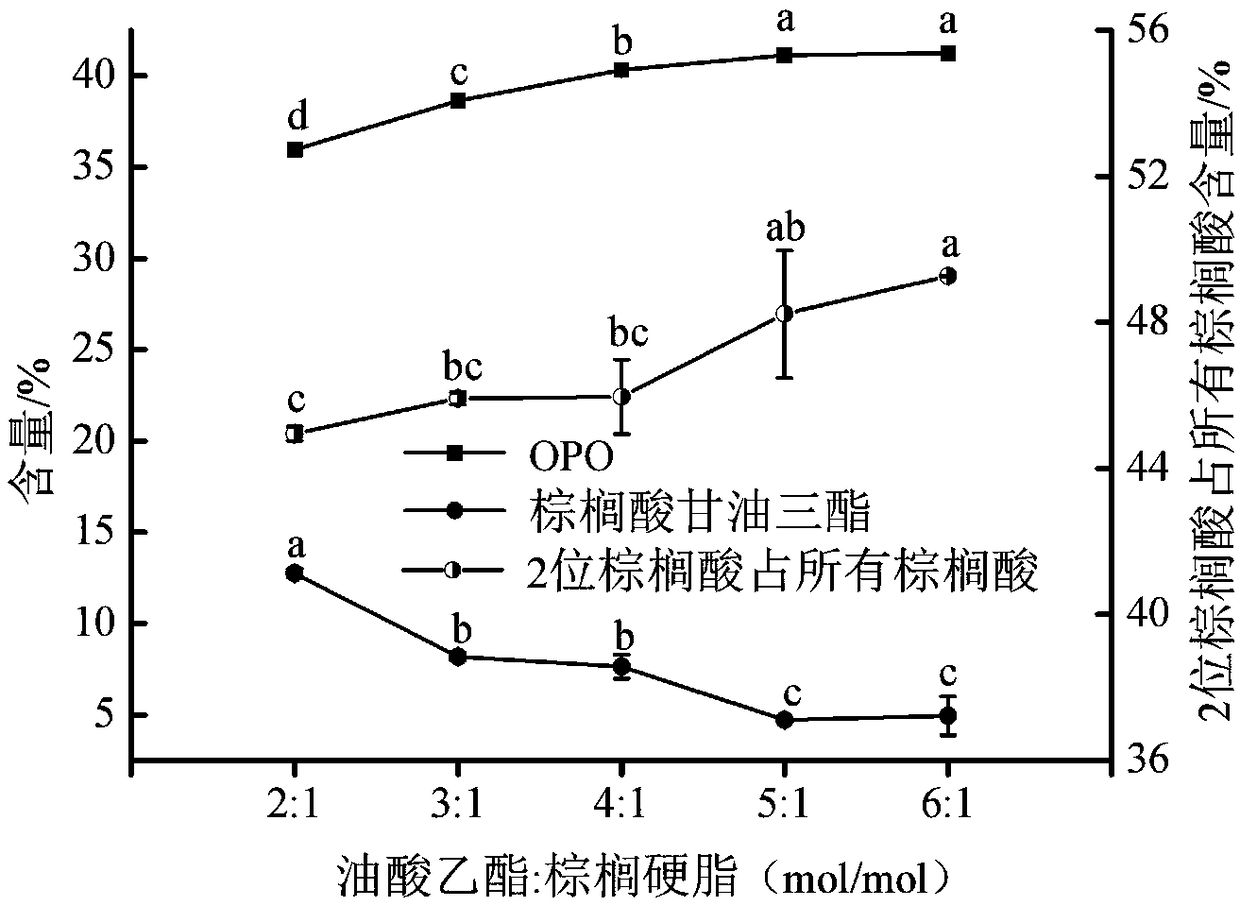

[0065] 2) The fatty acid ethyl ester and palm stearin obtained in step 1) are weighed in a molar ratio of 2:1, 3:1, 4:1, 5:1, 6:1, wherein the palm stearin is 20g, 0.0225mol . The weighed fatty acid ethyl ester and palm stearin were placed in a 25...

Embodiment 2

[0082] The molar ratio of fatty acid ethyl ester to palm stearin is 5:1, and the transesterification time is 30min, 1h, 2h, 4h, 6h respectively. Other reaction conditions are identical with embodiment 1. Obtain the target product.

[0083] Figure 4 It is the influence of transesterification reaction time on synthetic effect in embodiment 2.

[0084] Depend on Figure 4 It can be seen that when the reaction time increased from 30min to 6h, the OPO content and the 2-position palmitic acid accounted for all palmitic acid content first increased and then decreased, and the palmitic triglyceride content first decreased and then stabilized. As the reaction time increased from 30min to 1h, the reaction proceeded in the direction of positive reaction, the reaction was more complete, the content of the target product increased significantly, and the reaction reached equilibrium at 1h, the OPO content was 44.07%, and the 2-position palmitic acid accounted for all palmitic acid The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com