Preparation method of polyaniline/ruthenium oxide/tin dioxide composite electrode material

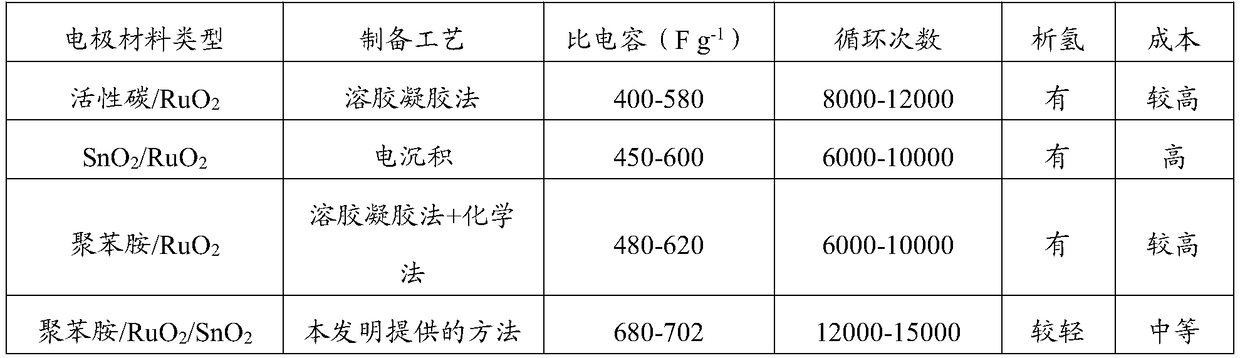

A composite electrode, polyaniline technology, used in hybrid capacitor electrodes, electrolytic organic material coating, hybrid/electric double layer capacitor manufacturing and other directions, can solve the problems of low charge and discharge rate, low cycle times, etc. The effect of improving the specific capacitance value and excellent cyclic charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a polyaniline / RuO 2 / SnO 2 The preparation method of composite electrode material comprises the following steps:

[0027] SnO was deposited by magnetron sputtering 2 The target material is deposited on the surface of the tantalum substrate, forming SnO on the surface of the tantalum substrate 2 retouching layer;

[0028] RuCl 3 solution, porous silica molecular sieve and NH 4 HCO 3 Mix, carry out the synthesis reaction, and activate the resulting product to obtain RuO 2 Nanoparticles;

[0029] The RuO 2 Nanoparticles are mixed with conductive carbon black, polyvinylidene fluoride and nitrogen methylpyrrolidone, and the resulting mixed slurry is coated on the SnO 2 layer surface and form RuO after solidification 2 middle active layer;

[0030] In the RuO 2 Electrodeposition of polyaniline on the surface of the intermediate active layer yields polyaniline / RuO 2 / SnO 2 Composite electrode material.

[0031] The present invention adopts...

Embodiment 1

[0040] Select high-purity tantalum foil for wire cutting, so that its diameter is 50 mm; use metallographic sandpaper with a particle size of 500 mesh to polish the tantalum substrate until the oxide layer on the surface of the tantalum substrate is completely removed; place the polished tantalum substrate in an ultrasonic cleaner, Use acetone and mixed lye (ingredients: 5g L -1 NaOH, 10g·L -1 Na 2 CO 3 , 20g·L -1 Na 3 PO 4 and 15g·L -1 Na 2 SiO 3 ) for degreasing for 5 minutes; then use an atmospheric plasma cleaning agent to perform ultra-clean cleaning on the surface of the degreased tantalum substrate, and keep the distance between the tantalum substrate and the plasma flame nozzle at 3 cm, and the cleaning time is 5 minutes;

[0041] The treated tantalum substrate and SnO 2 The sputtering targets were respectively installed in the corresponding fixtures in the magnetron sputtering chamber, and vacuumed to 0.5×10 -3 Pa, followed by injection of N 2 Make the pres...

Embodiment 2

[0048] Select high-purity tantalum foil for wire cutting, so that the diameter is 70mm; use metallographic sandpaper with a particle size of 600 mesh to polish the tantalum substrate until the oxide layer on the surface of the tantalum substrate is completely removed; place the polished tantalum substrate in an ultrasonic cleaner, Use acetone and mixed lye (ingredients: 5g L -1 NaOH, 10g·L -1 Na 2 CO 3 , 20g·L -1 Na 3 PO 4 and 15g·L -1 Na 2 SiO 3 ) for degreasing for 5 minutes; then use an atmospheric plasma cleaning agent to perform ultra-clean cleaning on the surface of the degreased tantalum substrate, and keep the distance between the tantalum substrate and the plasma flame nozzle at 3 cm, and the cleaning time is 5 minutes;

[0049] The treated tantalum substrate and SnO 2 The sputtering targets were respectively installed in the corresponding fixtures in the magnetron sputtering chamber, and vacuumed to 0.5×10 -3 Pa, followed by injection of N 2 Make the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com