Preparation method of magnetic polystyrene-based bentonite composite adsorbent

A polystyrene-based, composite adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problem that water quality cannot be effectively guaranteed, and sewage impurities and chemical components cannot be effectively purified and other problems, to achieve the effect of enhancing mechanical strength and magnetic recovery capacity, good recycling performance, and rapid adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

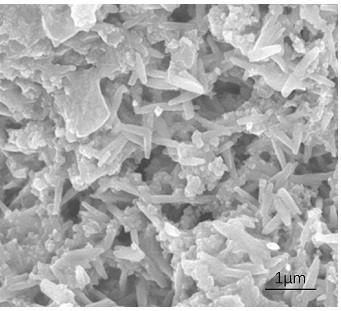

Image

Examples

Embodiment 1

[0016] A preparation method of magnetic polystyrene-based bentonite composite adsorbent, the method specifically comprises the following steps:

[0017] Step (1): Add Ag hydroxycalcium phosphate and 5g sodium dodecylbenzenesulfonate as a dispersant into deionized water, add 1mL hydrogen peroxide as an initiator, and add styrene monomer under stirring conditions, Styrene monomer is suspended in water in the form of droplets, and polymerized according to the free radical reaction process; then add 0.03g / L potassium persulfate aqueous solution, heat up to 80°C, stir for 30 hours, and then centrifuge to retain the solid The substance was washed with water, sonicated, and dried to obtain a white solid, namely polystyrene microspheres;

[0018] Step (2): Disperse the polystyrene microspheres prepared in step (1) into deionized water, and 2 Add 2g Fe (NO 3 ) 3 and 2g Fe (NO 3 ) 2 , continuously stirred for 4 hours, added ammonia water, and continued to stir for 5 hours to obtain...

Embodiment 2

[0025] A preparation method of magnetic polystyrene-based bentonite composite adsorbent, the method specifically comprises the following steps:

[0026] Step (1): Add 5g of calcium hydroxyphosphate and 5g of sodium dodecylbenzenesulfonate as dispersants into deionized water, add 1mL of hydrogen peroxide as an initiator, and add styrene monomer under stirring conditions, Styrene monomer is suspended in water in the form of droplets, and polymerized according to the free radical reaction process; then add 0.03g / L potassium persulfate aqueous solution, heat up to 80°C, stir for 30 hours, and then centrifuge to retain the solid The substance was washed with water, sonicated, and dried to obtain a white solid, namely polystyrene microspheres;

[0027] Step (2): Disperse the polystyrene microspheres prepared in step (1) into deionized water, and 2 Add 2g Fe (NO 3 ) 3 and 2g Fe (NO 3 ) 2 , continuously stirred for 4 hours, added ammonia water, and continued to stir for 5 hours t...

Embodiment 3

[0034] A preparation method of magnetic polystyrene-based bentonite composite adsorbent, the method specifically comprises the following steps:

[0035] Step (1): Add 5g of calcium hydroxyphosphate and 5g of sodium dodecylbenzenesulfonate as dispersants into deionized water, add 1mL of hydrogen peroxide as an initiator, and add styrene monomer under stirring conditions, Styrene monomer is suspended in water in the form of droplets, and polymerized according to the free radical reaction process; then add 0.03g / L potassium persulfate aqueous solution, heat up to 80°C, stir for 30 hours, and then centrifuge to retain the solid The substance was washed with water, sonicated, and dried to obtain a white solid, namely polystyrene microspheres;

[0036] Step (2): Disperse the polystyrene microspheres prepared in step (1) into deionized water, and 2 Add 2g Fe (NO 3 ) 3 and 2g Fe (NO 3 ) 2 , continuously stirred for 4 hours, added ammonia water, and continued to stir for 5 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com