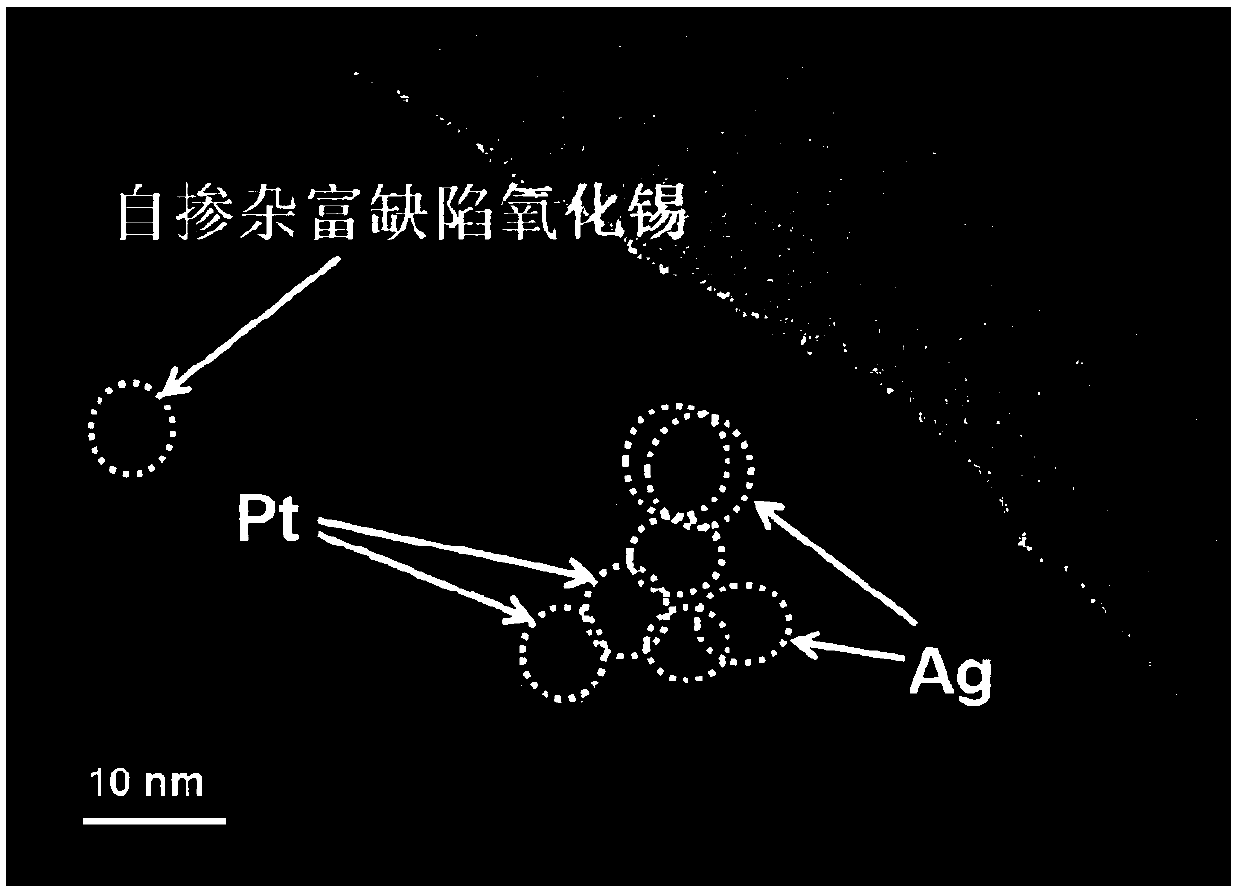

Preparation method of LSPR effect-based metal modified self-doped defect-enriched tin oxide nano composite material

A nanocomposite material and metal modification technology, which is applied in the field of preparation of tin oxide nanocomposite materials, can solve the problems of difficult PICS and low cost, and achieve the effects of improving lifespan, improving electrical conductivity and tight interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) get 1mmol analytically pure stannous methanesulfonate ((CH 3 SO 3 ) 2 Sn) and 3.2mmol of citric acid are fully dissolved in 4mL of absolute ethanol, then add 0.5mmol of phytic acid and 10mL of deionized water successively, then adjust its pH value to 10 with 8mol / L NaOH solution, the whole process In the ice-salt bath of NaCl and crushed ice, use a constant temperature magnetic stirring device to continuously magnetically stir it at -20°C to obtain solution A;

[0034] 2) get 0.5mmol analytically pure chloroplatinic acid (H 2 PtCl 6 ), 1mmol of chloroauric acid (HAuCl 4 ) and 5 mmol of citric acid were fully dissolved in 8 mL of deionized water, and then used a constant temperature magnetic stirring device in an ice-salt bath of NaCl and crushed ice to carry out continuous magnetic stirring and mixing at a temperature of -20 ° C to obtain a uniform solution B;

[0035] 3) Add solution B dropwise to solution A at a rate of 30 drops / min. During the whole dropping...

Embodiment 2

[0039] 1) get 1mmol analytically pure stannous methanesulfonate ((CH 3 SO 3 ) 2Sn) and 4mmol of citric acid are fully dissolved in 6mL of absolute ethanol, then add 5mmol of phytic acid and 20mL of deionized water successively, then adjust its pH value to 6 with 4mol / L NaOH solution, the whole process is in NaCl In the ice-salt bath with crushed ice, use a constant temperature magnetic stirring device to continuously magnetically stir it at -10°C to obtain solution A;

[0040] 2) get 0.2mmol analytically pure chloroplatinic acid (H 2 PtCl 6 ), 1.5mmol of silver nitrate (AgNO 3 ) and 7 mmol of citric acid were fully dissolved in 13 mL of deionized water, and then used a constant temperature magnetic stirring device in an ice-salt bath of NaCl and crushed ice to carry out continuous magnetic stirring and mixing at a temperature of -10 ° C to obtain a uniform solution B;

[0041] 3) Add solution B dropwise to solution A at a rate of 40 drops / min. During the whole dropping p...

Embodiment 3

[0046] 1) get 1mmol analytically pure stannous methanesulfonate ((CH 3 SO 3 ) 2 Sn) and the citric acid of 8.7mmol are fully dissolved in the dehydrated alcohol of 10mL, then add the phytic acid of 9mmol and the deionized water of 25mL successively, then adjust its pH value to be 4 with the NaOH solution of 1mol / L, the whole process is in In the ice-salt bath of NaCl and crushed ice, use a constant temperature magnetic stirring device to continuously magnetically stir it at 10°C to obtain solution A;

[0047] 2) get 0.5mmol analytically pure chloroplatinic acid (H 2 PtCl 6 ), 2mmol of silver nitrate (AgNO 3 ), 7mmol of copper nitrate (Cu(NO 3 ) 2 ) and 12mmol of citric acid were fully dissolved in 20mL of deionized water, and then used a constant temperature magnetic stirring device in an ice-salt bath of NaCl and crushed ice to carry out continuous magnetic stirring and mixing at a temperature of 10°C to obtain solution B ;

[0048] 3) Add solution B dropwise to solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com