Preparation method of catalyst for preparing 5-hydroxymethylfurfural from cellulose

A technology of hydroxymethyl furfural and catalyst, applied in the field of nano catalyst preparation, can solve the problems of cumbersome reaction steps, complex species selection, environmental burden and the like, and achieves the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

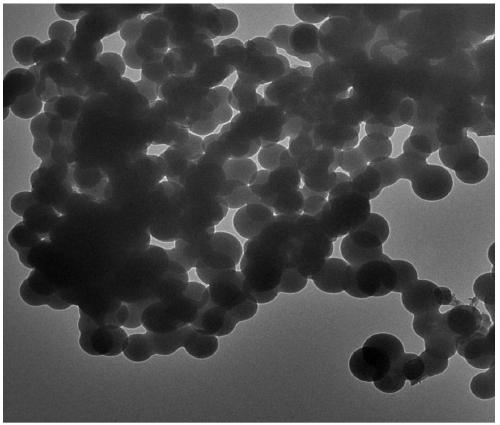

Image

Examples

Embodiment 1

[0020] Choose glucose as the raw material, water as the solvent, and nickel acetate tetrahydrate as the nickel source, and control the ratio of the two to 5:1. After mixing evenly, pour it into a polytetrafluoroethylene-lined reaction kettle, put it into a muffle furnace, and heat it to 190°C, constant temperature reaction for 6 hours, after the reaction kettle was cooled to room temperature, it was filtered and washed to obtain a dark brown nickel-doped carbon composite. The obtained dried product was put into a tubular calciner, and the temperature was raised to 900° C. under a nitrogen atmosphere, and the temperature was kept constant for 3 hours to obtain a nickel-doped carbon catalyst.

[0021] 200mg of the obtained catalyst, 1g of cellulose, and 100ml of water are used as the reaction solvent. After mixing evenly, put it into a high-temperature and high-pressure reactor, and feed hydrogen gas to ensure that the hydrogen pressure is maintained at 4MPa during the reaction. ...

Embodiment 2

[0023] Select larch powder as raw material, water as solvent, nickel hydroxide as nickel source, control the ratio of raw material and nickel source to 2:1, mix well and pour it into a polytetrafluoroethylene-lined reaction kettle, and put it into a muffle furnace , heated to 230°C, and reacted at a constant temperature for 5 hours. After the reactor was cooled to room temperature, it was filtered and washed to obtain a dark brown nickel-doped carbon composite. Put the obtained dry product into a tubular calciner, raise the temperature to 800° C. under a nitrogen atmosphere, and keep the temperature constant for 2 hours to obtain a nickel-doped carbon catalyst.

[0024] 500mg of the obtained catalyst, 1g of cellulose, and 100ml of water are used as the reaction solvent. After mixing evenly, put it into a high-temperature and high-pressure reactor, and feed hydrogen to ensure that the hydrogen pressure is maintained at 6MPa during the reaction. Heat up to 200°C and react for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com