Method for preparing CC (carbon cloth) supported nickel selenide on basis of solution method

A technology of nickel selenide and solution method, which is applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of poor repeatability, waste of raw materials, and unsafety of electrodeposition methods, and achieve improved electrodeposition. Catalytic performance, reduced preparation cost, good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Drop-coating the precursor solution on the carbon cloth

[0028] The precursor solution is prepared by dissolving nickel hydroxide powder and selenium powder in a thiolamine solution at a molar ratio of 0.98 to 1.02, and the thiolamine solution is composed of ethylenediamine and ethanedithiol in a volume ratio of 4:1 Dissolved; the concentration of the precursor solution is 0.145mmol / mL;

[0029] Drop-coat 0.16mL precursor solution on a 1cm*1cm carbon cloth;

[0030] (2) Preparation of carbon cloth supported nickel selenide

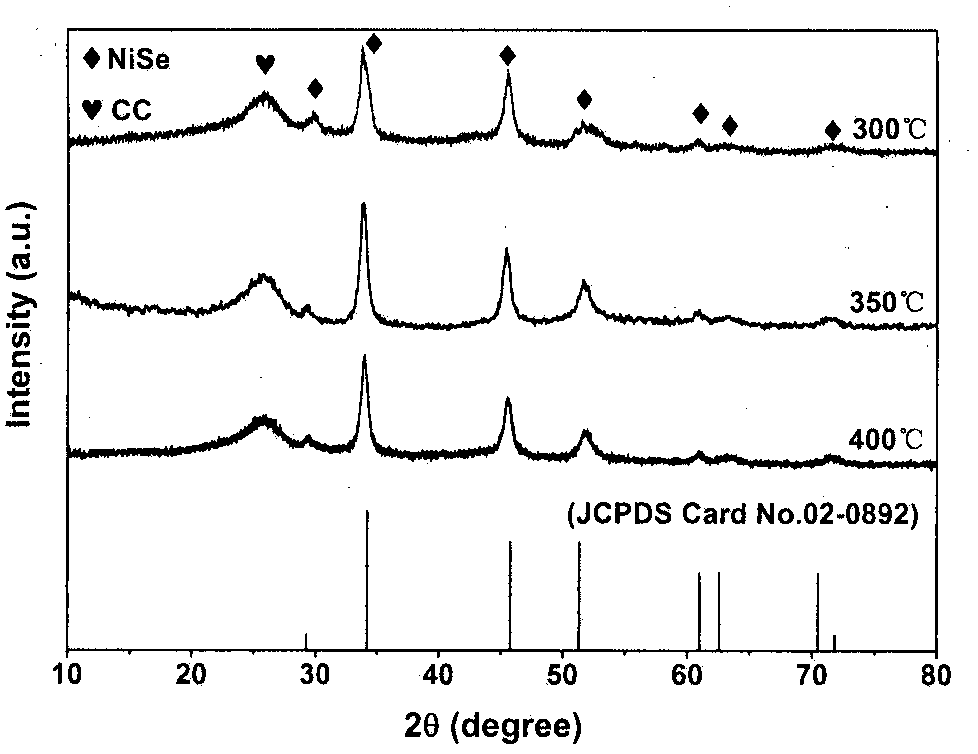

[0031] The carbon onto which the precursor solution was drip-coated in step (1) was placed on a heating plate, and heated at 350°C for 60s, and finally carbon cloth supported nickel selenide (NiSe / CC) was obtained. X-ray diffraction pattern ( figure 1 ) in (100), (101), (102), (110), (103), (201) and (202) crystal planes correspond to the standard card JCPDS No.02-0892 respectively, and are proved to be phase-pure Nickel Selenide, showing t...

Embodiment 2

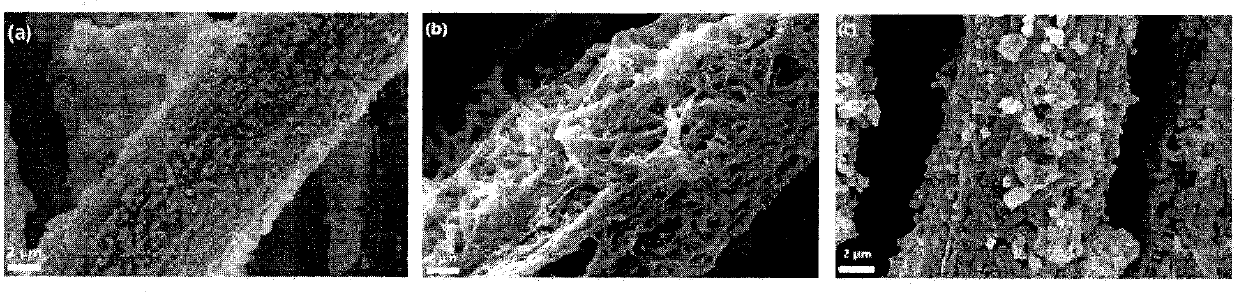

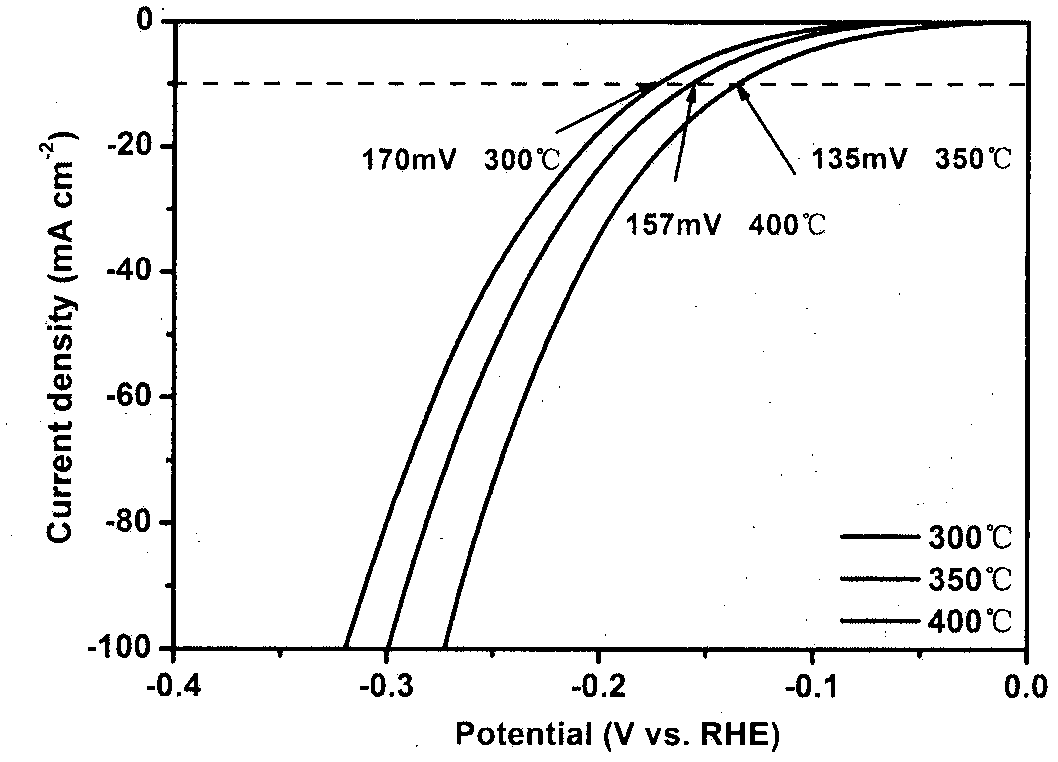

[0033] The other steps are the same as in Example 1, except that the heating temperature is changed from 350°C to 300°C and 400°C. As a result, nickel selenide supported on carbon cloth is also obtained, and the nickel selenide prepared under the condition of 300°C It is coated on carbon cloth (CC) in the form of nano-particle accumulation, but the coating is not complete, and part of the carbon cloth is exposed. The specific appearance is as follows figure 2 Shown in a; the prepared sample is applied to electrocatalysis, and its HER overpotential is -170mV. Compared with the HER overpotential of nickel selenide nanomaterials prepared by Wang Chunming's research group by electrodeposition method, the HER overpotential is reduced by 100mV, and the specific polarization curve of the sample is as follows: image 3 shown. In addition, nickel selenide prepared at 400°C is coated on carbon cloth (CC) in the form of nano-particle accumulation, and the carbon cloth is evenly wrapped...

Embodiment 3

[0035] Other steps are the same as in Example 1, except that the heating time is changed from 60s to 40s and 80s. As a result, nickel selenide supported on carbon cloth was also obtained, and the morphology was close to that of Example 1. Among them, the nickel selenide prepared under the condition of heating time of 40s is applied to electrocatalysis, and its HER overpotential is -145mV, compared with the HER overpotential of nickel selenide nanomaterials prepared by Zou Xiaoxin's group by hydrothermal method. The potential is reduced by 16mV; compared with the HER overpotential of nickel selenide nanomaterials prepared by Wang Chunming's research group by electrodeposition method, the HER overpotential is reduced by 125mV. The specific polarization curve of the sample is as follows Figure 4 shown. In addition, the nickel selenide prepared under the condition of heating time of 80s is applied to electrocatalysis, and its HER overpotential is -156mV, compared with the HER ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com