Copper metal organic framework mimic enzyme material as well as preparation and application thereof

An organic skeleton and enzyme-mimicking technology, applied in the field of enzyme-mimicking, can solve problems such as impeding the popularization and application of natural enzymes, difficulty in the application of natural enzymes, and high cost, and achieve excellent catalytic effects, intuitive and obvious effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of sheet-like Cu-MOFs mimic enzyme material

[0028] 1) Add 0.2mmol copper nitrate to 0.5mL N, N-dimethylformamide, and obtain 0.4mol / L solution A after magnetic stirring; add 0.2mmol 5-nitroisophthalic acid to 0.5mL N , in N-dimethylformamide, after magnetic stirring, 0.4mol / L solution B was obtained; solution A and 4mL methanol were added to solution B under stirring conditions, stirred for 20-40 minutes and then placed in a reaction kettle, At 75°C, react at a constant temperature for 48 hours; after the reaction is completed and cooled to room temperature, centrifuge and wash at a speed of 5000rpm, and then dry at 60°C for 24 hours to obtain a sheet-like Cu-MOFs mimic enzyme material (see figure 1 ). 4 mg of this material was dispersed into 20 mL of deionized water to obtain a 0.2 mg / mL Cu-MOFs mimic enzyme aqueous solution.

Embodiment 2

[0029] Example 2 Preparation of sheet Cu-MOFs mimic enzyme material

[0030] The difference from Example 1 is that the amounts of copper nitrate and 5-nitroisophthalic acid are both changed to 0.6 mmol. Add 0.6mmol copper nitrate to 0.5mL N,N-dimethylformamide, and obtain 1.2mol / L solution A after magnetic stirring; add 0.6mmol 5-nitroisophthalic acid to 0.5mL N,N - In dimethylformamide, after magnetic stirring, a solution B of 1.2 mol / L was obtained; solution A and 4 mL of methanol were added to solution B under stirring, and placed in a reaction kettle after stirring for 20 to 40 minutes. At 75°C, react at a constant temperature for 48 hours; after the reaction is completed and cooled to room temperature, centrifuge and wash at a speed of 5000 rpm, and then dry at 60°C for 24 hours to obtain a sheet-like Cu-MOFs simulation material, whose shape and size are the same as Embodiment 1 is consistent.

Embodiment 3

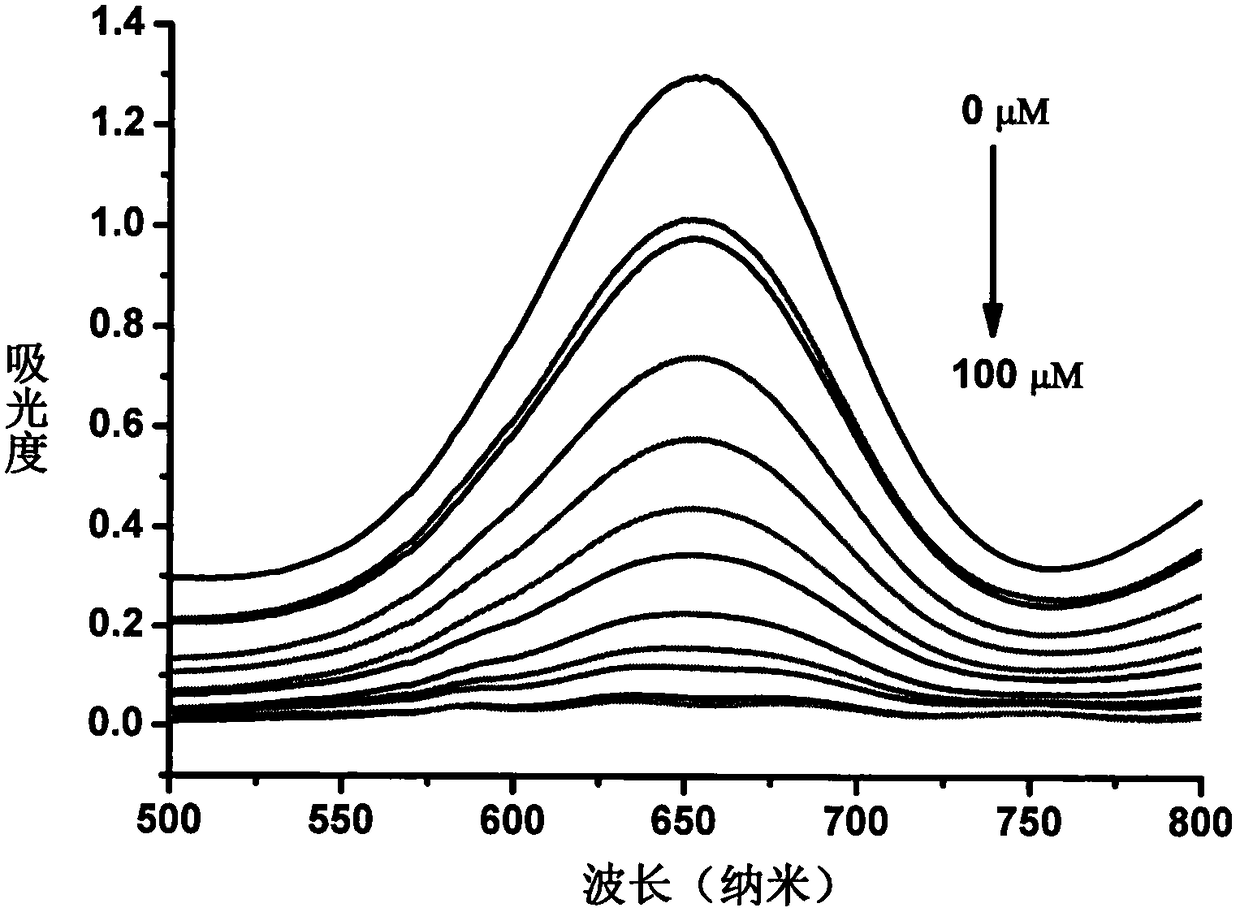

[0031] Example 3 To investigate the catalytic activity of the Cu-MOFs mimic enzyme material as a peroxide mimic enzyme, the following operations were performed:

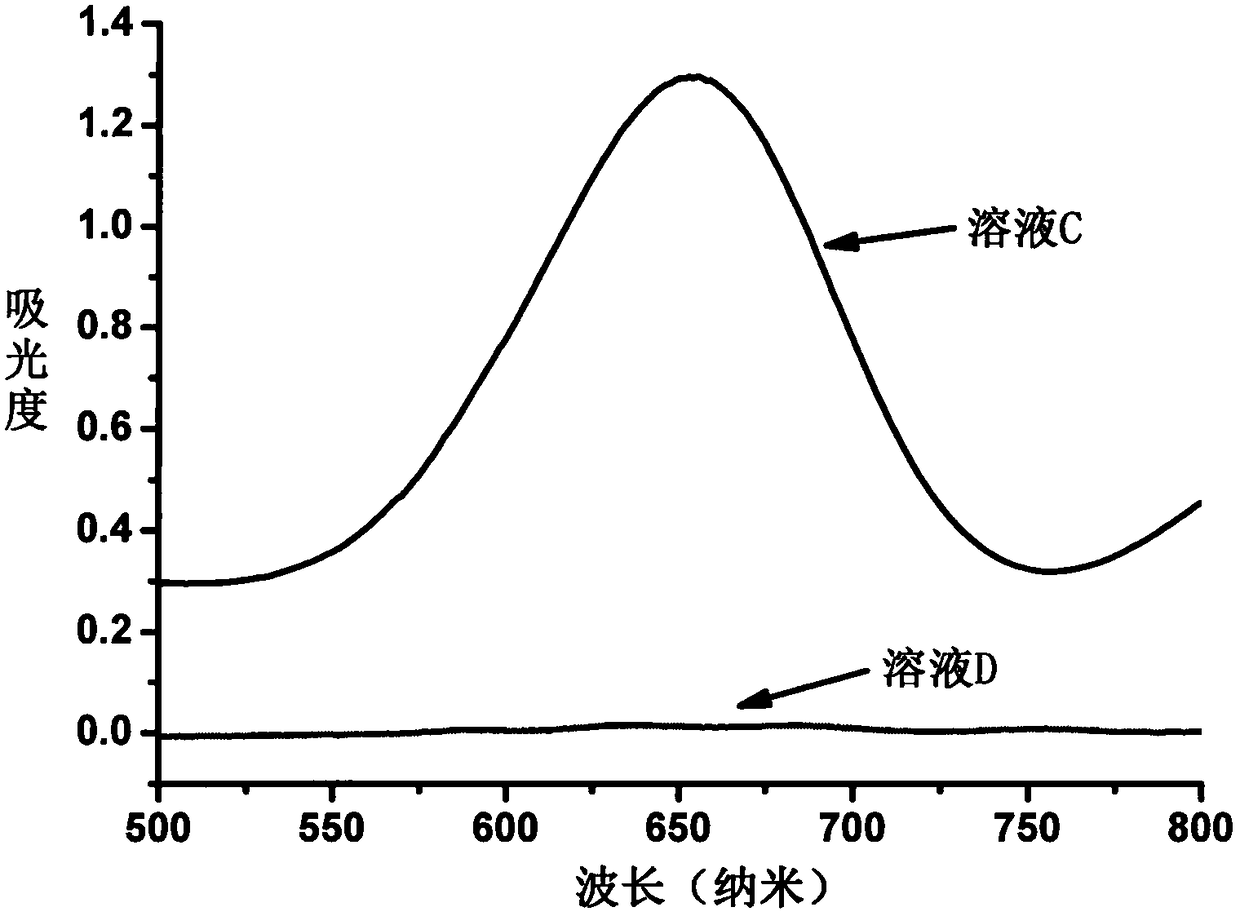

[0032]Add 200 μL 0.2 mg / mL Cu-MOFs simulated enzyme solution, 200 μL pH=7.0 MOPS buffer solution, 200 μL 5 mM 3,3′,5,5′-tetramethylbenzidine, 80 μL 100 mM H 2 o 2 Solution and deionized water, so that the reaction system was 2mL, and solution C was obtained; 200μL buffer solution with pH=7.0, 200μL 5mM 3,3′,5,5′-tetramethylbenzidine solution, 80μL 100mM H 2 o 2 Solution and deionized water, so that the reaction system is 2mL, to obtain solution D; after reacting at 20°C for 5min, use a UV-visible spectrophotometer to detect the absorption spectra of solutions C and D respectively at 500-800 (see figure 2 ).

[0033] attached figure 2 It is shown that the sheet-like Cu-MOFs mimic enzyme material has peroxide mimic enzyme activity and has good catalytic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com