Catalyst composition and preparation method of 2-butenoic acid

A technology of composition and catalyst, applied in chemical instruments and methods, carbon monoxide reaction to prepare carboxylic acid, physical/chemical process catalyst, etc., can solve the problems of low conversion rate of propyne and low selectivity of 2-butenoic acid, and achieve Improve the conversion rate and the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

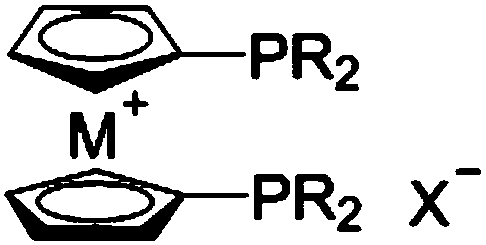

Method used

Image

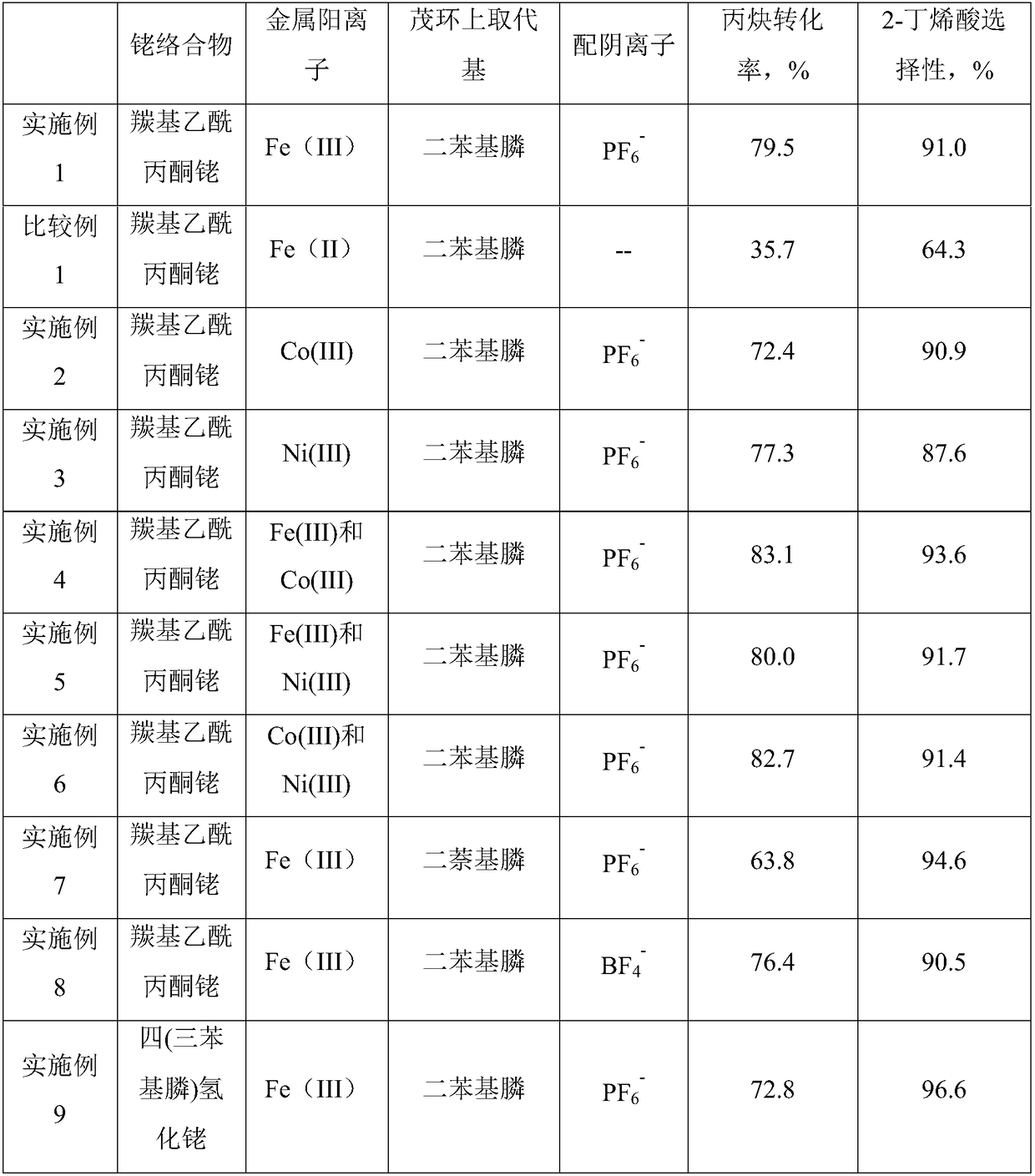

Examples

Embodiment 1

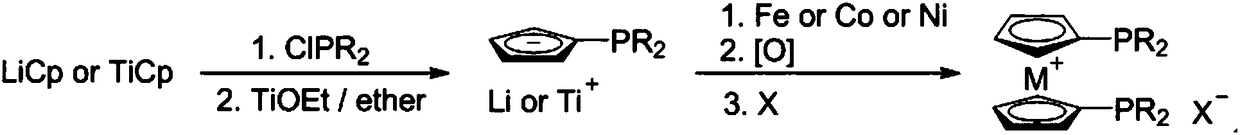

[0041] 1. Ligand synthesis

[0042] Dissolve 50 mmol of newly prepared lithrocene or titanocene in anhydrous ether, cool the system to -30°C, add 50 mmol of diphenylphosphine chloride, and stir at room temperature for 2 hours. Diatomaceous earth was filtered, and the filtrate was cooled to -78°C, and 50 mmol of titanium ethoxide in anhydrous ether solution was added dropwise, and the mixture was allowed to return to room temperature naturally, and stirred for 2 hours. Add 25mmol ferrous chloride, and reflux for 12 hours. Cool the solution to room temperature, add 60mmol p-benzoquinone or perchloroethane, react for 10 minutes, distill off the solvent under reduced pressure, dissolve the residue with dichloromethane, filter with diatomaceous earth, evaporate the solvent under reduced pressure, and dissolve the residue in acetone Add 75mmol sodium hexafluorophosphate, then add water, extract with dichloromethane, drop the solution into ether, filter to obtain a solid, and then r...

Embodiment 2

[0049] 1. Ligand synthesis

[0050] Dissolve 50 mmol of newly prepared lithrocene or titanocene in anhydrous ether, cool the system to -30°C, add 50 mmol of diphenylphosphine chloride, and stir at room temperature for 2 hours. Diatomaceous earth was filtered, and the filtrate was cooled to -78°C, and 50 mmol of titanium ethoxide in anhydrous ether solution was added dropwise, and the mixture was allowed to return to room temperature naturally, and stirred for 2 hours. Add 25mmol cobaltous chloride, and reflux for 12 hours. Cool the solution to room temperature, add 60mmol p-benzoquinone or perchloroethane, react for 10 minutes, distill off the solvent under reduced pressure, dissolve the residue with dichloromethane, filter with diatomaceous earth, evaporate the solvent under reduced pressure, and dissolve the residue in acetone , add 75mmol sodium hexafluorophosphate, then add water, extract with dichloromethane, drop the solution into diethyl ether, filter to obtain a solid...

Embodiment 3

[0054] 1. Ligand synthesis

[0055] Dissolve 50 mmol of newly prepared lithrocene or titanocene in anhydrous ether, cool the system to -30°C, add 50 mmol of diphenylphosphine chloride, and stir at room temperature for 2 hours. Diatomaceous earth was filtered, and the filtrate was cooled to -78°C, and 50 mmol of titanium ethoxide in anhydrous ether solution was added dropwise, and the mixture was allowed to return to room temperature naturally, and stirred for 2 hours. Add 25 mmol of nickel chloride, and reflux for 12 hours. Cool the solution to room temperature, add 60mmol p-benzoquinone or perchloroethane, react for 10 minutes, distill off the solvent under reduced pressure, dissolve the residue with dichloromethane, filter with diatomaceous earth, evaporate the solvent under reduced pressure, and dissolve the residue in acetone Add 75mmol sodium hexafluorophosphate, then add water, extract with dichloromethane, drop the solution into ether, filter to obtain a solid, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com