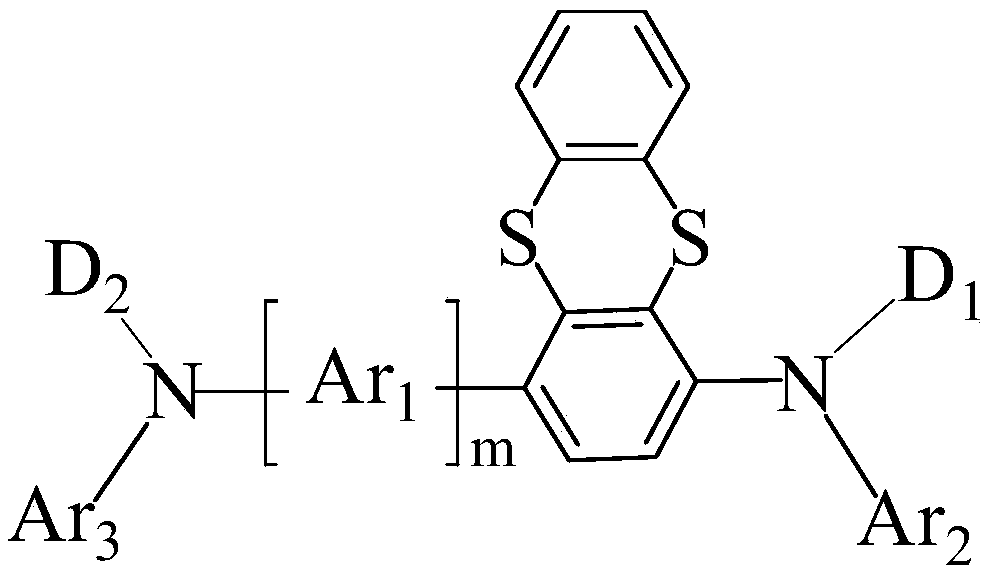

Thianthrene compound, display panel and display device

A display panel and compound technology, applied in organic chemistry, chemical instruments and methods, luminescent materials, etc., can solve the problems of large refractive index difference, high light extraction efficiency, and insufficient refractive index, and achieve extended length and red shift of absorption spectrum Inconspicuous, index-raising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Synthesis of Compound P1

[0088]

[0089] Weigh S1 (10mmol) into a 100mL two-necked flask, add 30mL nitrogen degassed toluene to dissolve S1, one of the ports is connected to a constant pressure dropping funnel, and nitrogen replaces the gas in the reaction system. Weigh NBS (10.5mmol), add 20mL of toluene to dissolve it, and add the toluene solution of NBS to the toluene solution of S9 dropwise through the dropping funnel at 0°C under the condition of protecting from light, and after stirring for 2h, slowly Warm to room temperature and stir overnight. After the reaction was completed, 50 mL of deionized water was added to quench the reaction, extracted with dichloromethane (100 mL × 3), and the organic phase was collected and washed with anhydrous Na 2 SO 4 Dry processing. After filtration, the solvent was distilled off under reduced pressure with a rotary evaporator to obtain a crude product. The crude product was purified by gradient elution of silica gel col...

Embodiment 2

[0100] Synthesis of Compound P3

[0101]

[0102] Under nitrogen protection, weigh compounds S6 (25mmol), S7 (25mmol), [Pd2(dba)3] CHCl3 (0.5mmol) and HP(tBu) 3 ·BF 4 (1.0mmol), was added to a 250mL two-necked flask. Inject 100mL of toluene into the two-necked flask (pass N in advance 2 15min to remove oxygen), and then add 12mL of K with a concentration of 1M dropwise 2 CO 3 Aqueous solution (pass N in advance 2 15min to remove oxygen), and stirred overnight at room temperature. After the reaction was completed, 100 mL of deionized water was added, followed by a few drops of 2M HCl. Extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and finally obtained solid S8 (20.5 mmol, yield 78%).

[0103] MALDI-TOF MS: C 18 h 10 Br 2 S ...

Embodiment 3

[0110] Synthesis of Compound P13

[0111]

[0112] Put S2 (10.0mmol), S9 (10.5mmol), tris(dibenzylideneacetone)dipalladium (0) (0.05mmol), sodium tert-butoxide (14mmol), tert-butylphosphine (0.2mmol) into 50mL three ports In the flask, while stirring, degassing and nitrogen replacement were rapidly repeated 3 times, and 20 mL of toluene was added through a syringe. The mixture was heated to reflux for 3 hours under nitrogen flow. After the reaction, water was added to the reaction solution left to cool to room temperature, extracted with dichloromethane, and washed with saturated brine. After drying the organic layer with anhydrous sodium sulfate, the solvent was distilled off and purified by column chromatography to obtain intermediate S10 (7.2 mmol, yield 72%).

[0113] MALDI-TOF MS: C 30 h 22 N 2 S 4 , calculated m / z: 538.1; tested: 538.4.

[0114]Elemental Analysis Calculated: C, 66.88; H, 4.12; N, 5.20; S, 23.81; Tested: C, 66.90; H, 4.15; N, 5.18;

[0115] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com