Preparation method of temperature-resistant high-intensity pocket-type dedusting filter fiber

A bag-type dust removal, high-strength technology, applied in separation methods, chemical characteristics of fibers, chemical instruments and methods, etc., can solve the problems of difficult processing, large damage, low strength, etc., and achieve strong adsorption and filtration effect and reasonable process matching. , the effect of high fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

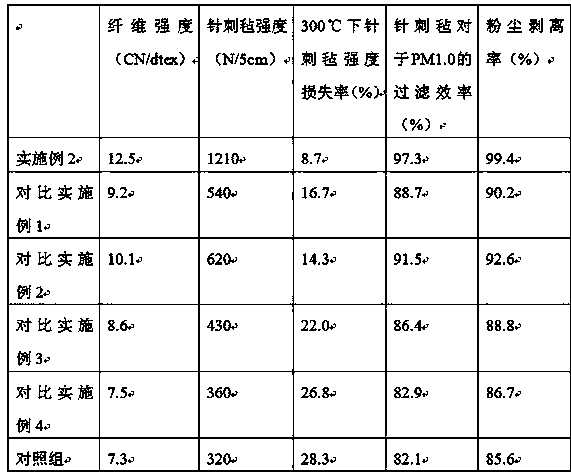

Examples

Embodiment 1

[0033] A method for preparing a temperature-resistant, high-strength bag filter fiber, comprising the steps of:

[0034] (1) Pretreatment of polyacrylonitrile powder:

[0035] Mix potassium permanganate, succinic acid, and ionic liquid into the mixing tank according to the weight ratio of 3:1:500, and after stirring continuously for 5 minutes, add polyacrylonitrile twice its total mass into the mixing tank Powder, after stirring continuously for 10 minutes, mixture A was obtained for subsequent use;

[0036] (2) Preparation of compound additives:

[0037]a. Mix multi-walled carbon nanotubes, fatty alcohol polyoxyethylene ether, and deionized water in a weight ratio of 1:7:100 and put them into a stirring tank, and then ultrasonically treat them for 1 hour to obtain a mixed solution B for later use;

[0038] b. Pour the mixed solution B obtained in operation a into the polytetrafluoroethylene filter membrane, and then use the suction filter to filter under the environment of ...

Embodiment 2

[0055] A method for preparing a temperature-resistant, high-strength bag filter fiber, comprising the steps of:

[0056] (1) Pretreatment of polyacrylonitrile powder:

[0057] Mix potassium permanganate, succinic acid, and ionic liquid into the mixing tank according to the weight ratio of 4:1.5:530, and after stirring continuously for 8 minutes, add polyacrylonitrile 2.5 times its total mass into the mixing tank Powder, after stirring continuously for 13 minutes, mixture A was obtained for subsequent use;

[0058] (2) Preparation of compound additives:

[0059] a. Mix multi-walled carbon nanotubes, fatty alcohol polyoxyethylene ether, and deionized water in a weight ratio of 1:8:105 and put them into a stirring tank, and then ultrasonically treat them for 1.5 hours to obtain a mixed solution B for later use;

[0060] b. Pour the mixed solution B obtained in operation a into the polytetrafluoroethylene filter membrane, and then use the suction filter to filter under the envir...

Embodiment 3

[0077] A method for preparing a temperature-resistant, high-strength bag filter fiber, comprising the steps of:

[0078] (1) Pretreatment of polyacrylonitrile powder:

[0079] Mix potassium permanganate, succinic acid, and ionic liquid into the mixing tank according to the weight ratio of 5:2:550, and after stirring continuously for 10 minutes, add polyacrylonitrile three times its total mass into the mixing tank Powder, after stirring continuously for 15 minutes, mixture A was obtained for subsequent use;

[0080] (2) Preparation of compound additives:

[0081] a. Mix multi-walled carbon nanotubes, fatty alcohol polyoxyethylene ether, and deionized water in a weight ratio of 1:9:110 and put them into a stirring tank, and then ultrasonically treat them for 2 hours to obtain a mixed solution B for later use;

[0082] b. Pour the mixed solution B obtained in operation a into the polytetrafluoroethylene filter membrane, and then use the suction filter to filter under the enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com