A passivation method for improving high and low temperature stability of SiC MOSFET Devices

A stable and low-temperature technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of not considering the temperature and the impact without specifying the evaluation, and achieve the effect of reducing the impact and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

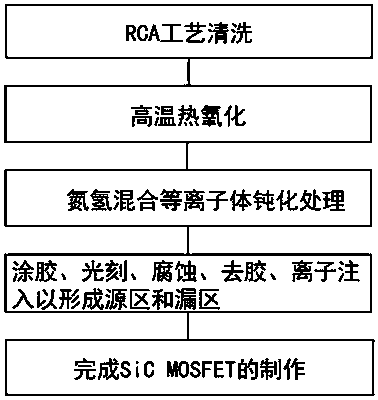

[0031] Such as figure 1 As shown, a passivation method for improving high and low temperature stability of SiC MOSFET devices includes the following steps:

[0032] Step 1, using RCA process cleaning, specifically including the following sub-steps:

[0033] (a) Place the silicon carbide wafer in a mixed solution of concentrated sulfuric acid and hydrogen peroxide, wash it at 100°C for 30 minutes, and rinse the surface of the silicon carbide wafer several times with deionized water. The volume ratio of the concentrated sulfuric acid and hydrogen peroxide is 1:1 ;

[0034] (b) Take out the silicon carbide wafer in sub-step (a) and place it in No. 1 cleaning solution, wash it at 80°C for 10 minutes, then wash it with a hydrofluoric acid aqueous solution with a concentration of 1%, and rinse the surface of the silicon carbide wafer with deionized water Several times, the No. 1 cleaning solution is a mixed solution composed of water, hydrogen peroxide and ammonia in a volume rati...

Embodiment 2

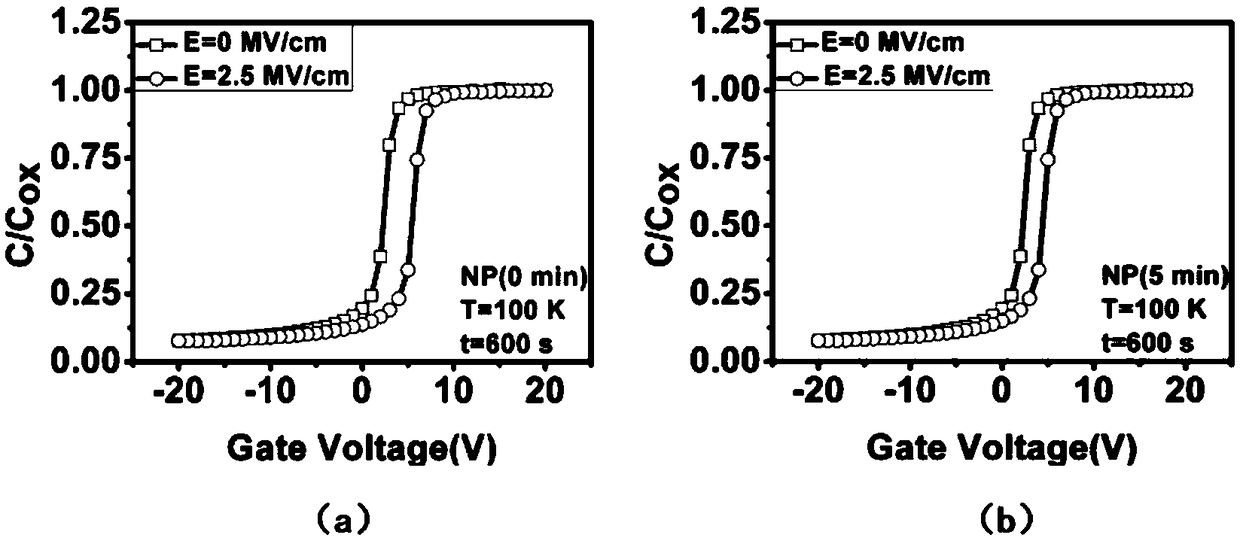

[0045] Low-temperature and high-frequency C-V curve tests were performed on SiC MOS devices that were not treated and treated with nitrogen plasma for 5 minutes. High frequency C-V curves were measured immediately again in situ. The measured results are as figure 2 As shown, wherein: (a) is the C-V drift curve of the sample without passivation treatment, and the flat-band voltage drift value at low temperature 100K is 3.14V (the flat-band voltage extracted from the C-V curve after normal stress and the mean extracted from the C-V curve before stress The difference of the belt voltage), the middle belt voltage drift value is 2.78V (the difference between the middle belt voltage extracted from the C-V curve after the normal stress and the middle belt voltage extracted from the C-V curve before the stress), and figure 2 (b) is the C-V drift curve of the sample treated with nitrogen plasma passivation for 5 minutes. The low-temperature 100K flat-band voltage drift value is 2.87...

Embodiment 3

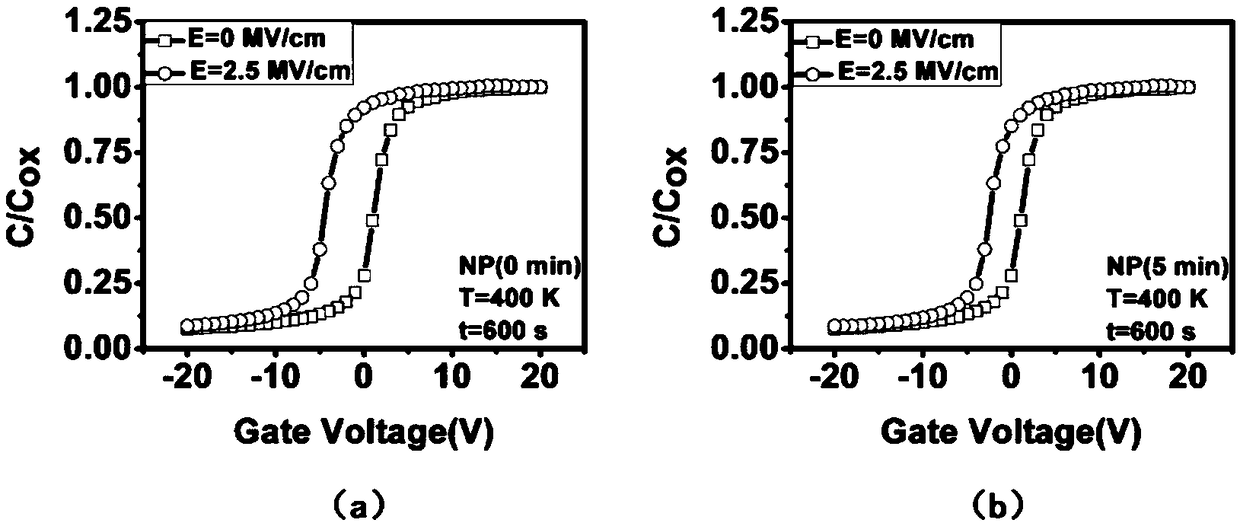

[0047] High-temperature and high-frequency C-V curve tests were performed on SiC MOS devices that were not treated and treated with nitrogen plasma for 5 minutes. High frequency C-V curves were measured immediately again in situ. The measured results are as image 3 As shown, where: (a) is the C-V drift curve of the sample without passivation treatment, the flat-band voltage drift value of the high temperature 400K is -7.25V, (b) is the C-V drift curve of the sample treated with nitrogen plasma passivation for 5 minutes , the high temperature 400K flat-band voltage drift value is -5.39V. Table 1 and Table 2 respectively show the flat-band voltage drift value and middle-band voltage drift value of SiC MOS samples with different nitrogen plasma passivation treatment times under normal stress when measured at 100K and 400K, and the middle-band voltage drift value under high temperature test The effect of other traps and charges cannot be calculated. It can be seen from the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com