An ultraviolet photoelectric detector based on a ZnO nano-grid and a preparation method thereof

A nano-grid and electrical detector technology, applied in the field of photoelectric detectors, can solve the problems of harsh conditions, lower production costs, and high equipment requirements, and achieve the effects of simple manufacturing equipment, convenient large-scale production, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

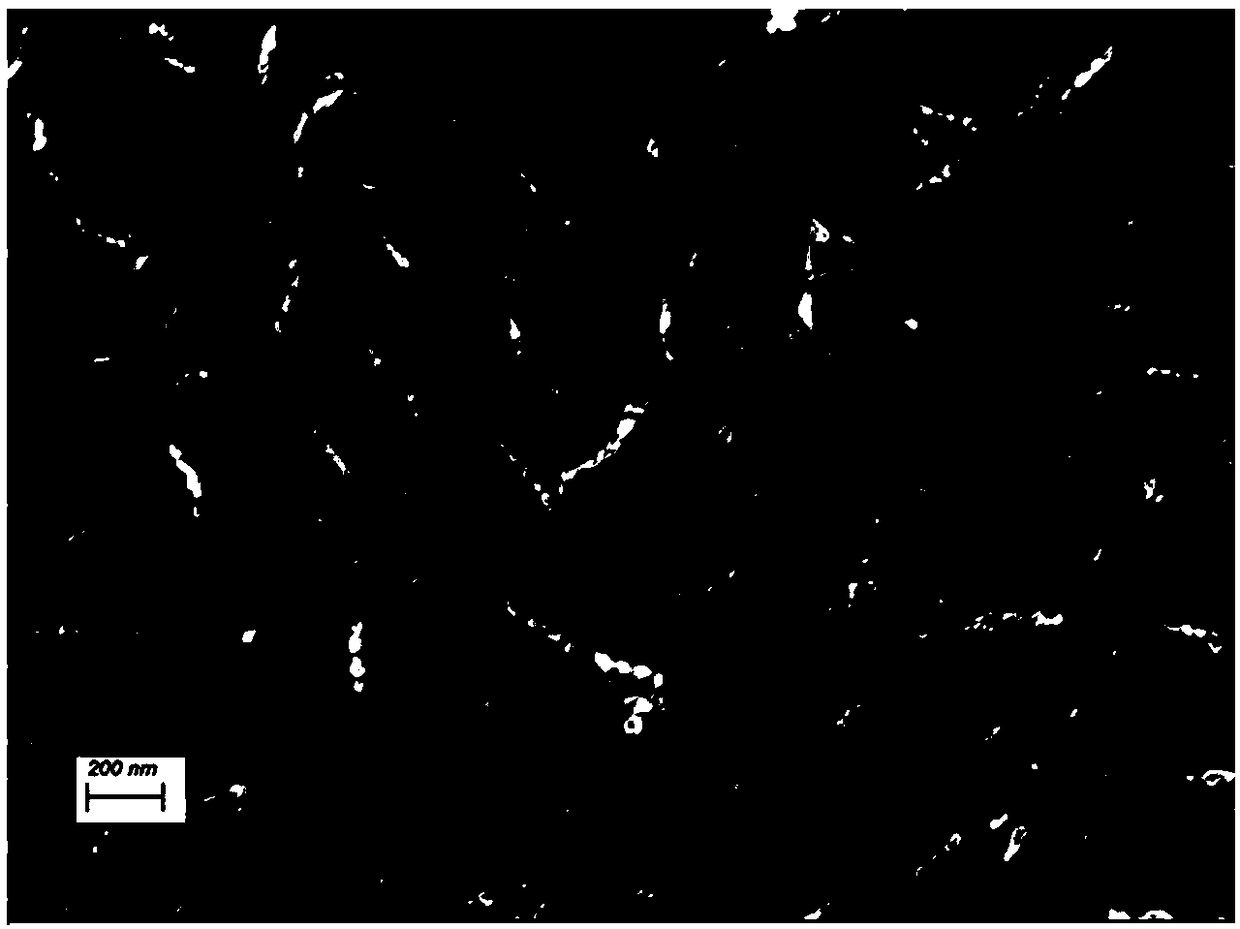

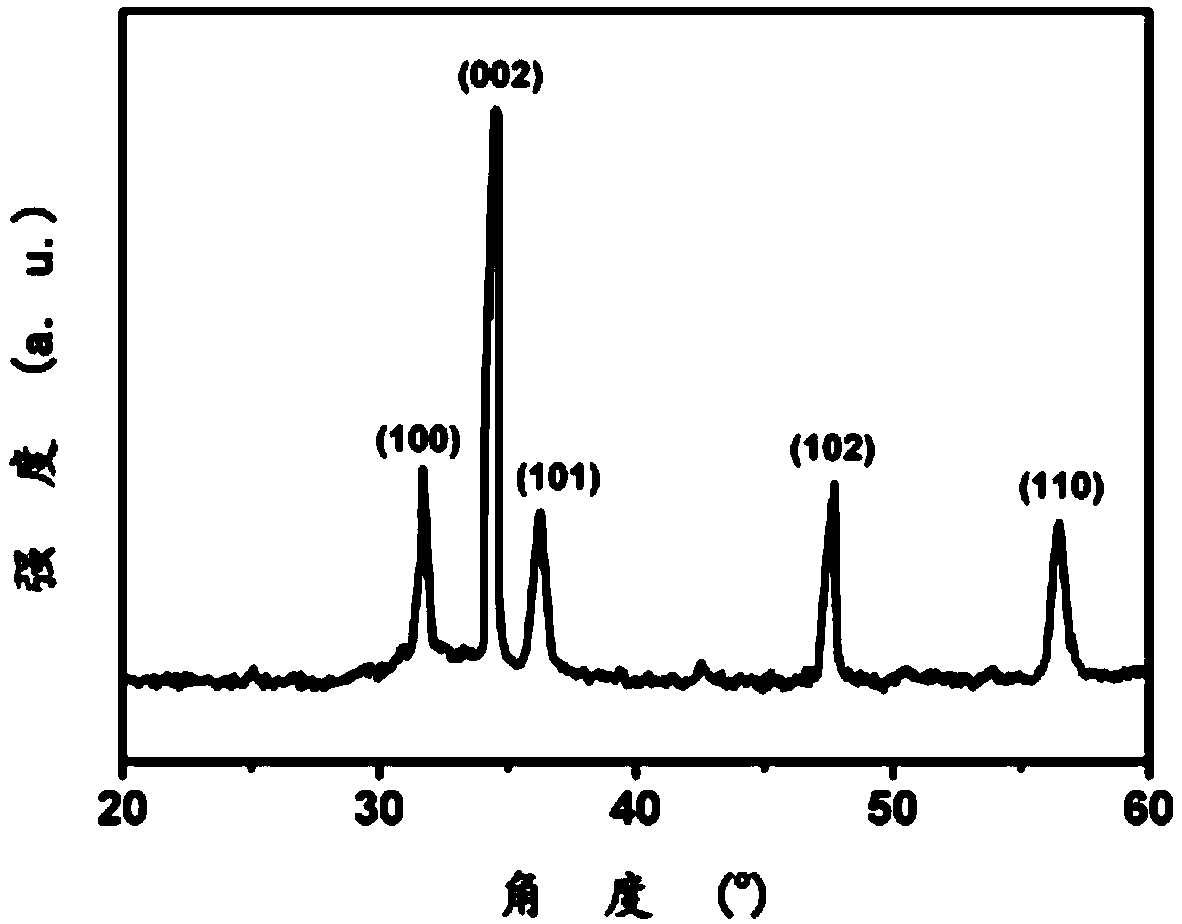

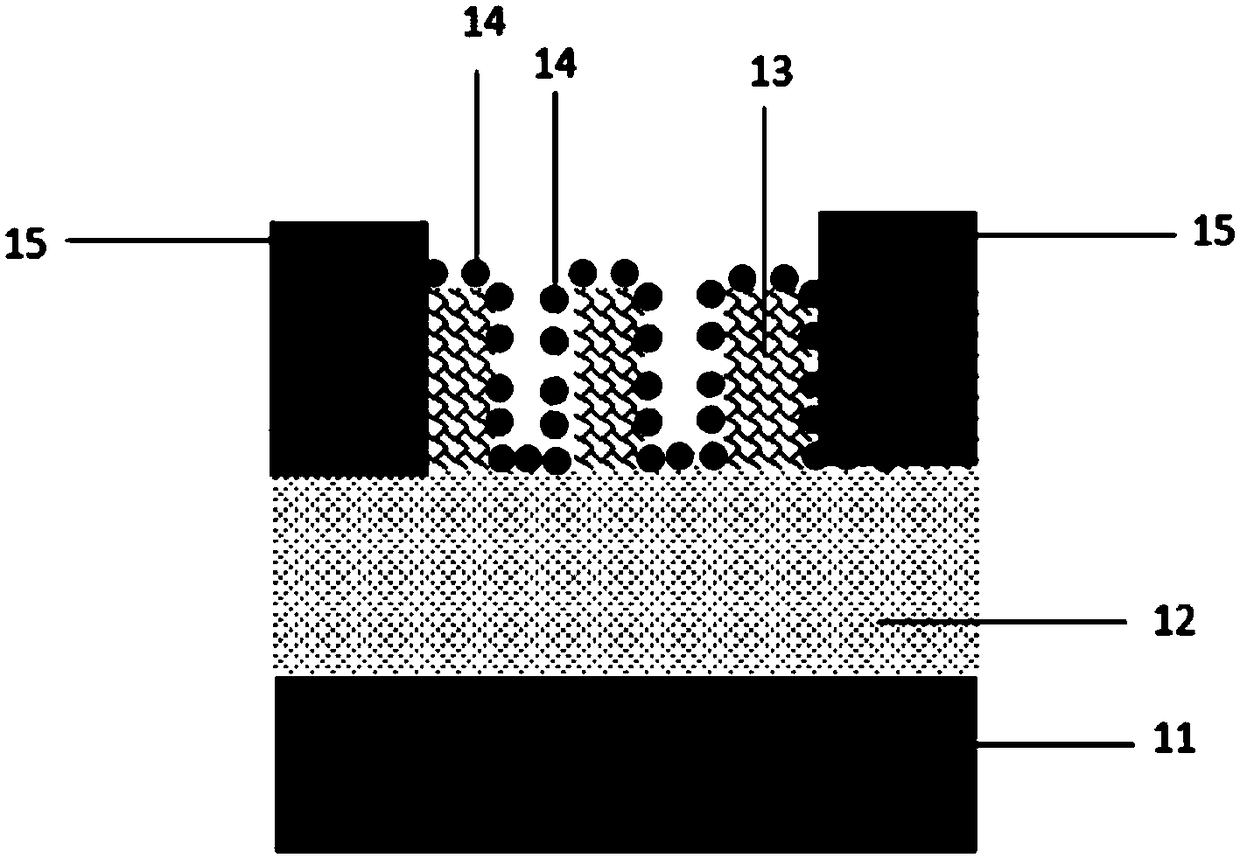

[0033] A method for preparing an ultraviolet photodetector based on ZnO nanogrids, comprising the following steps:

[0034] (1) Preparation of mixed solution: Zinc acetate and ethanol are prepared in a ratio of 0.08g:20mL to prepare a mixed solution, and a magnetic stirrer is used to stir for 30min to obtain a mixed solution A of zinc acetate and ethanol. Then, zinc acetate, zinc carbonate , ethanol is configured mixed solution by the ratio of 0.08g:0.035g:20mL; And use magnetic stirrer to stir 30min, obtain the mixed solution B of zinc acetate, zinc carbonate, ethanol;

[0035] (2) Preparation of thin film C: use one of glass, quartz, silicon wafer, sapphire, and metal plate as the substrate. The substrate size is 2cm×2cm. Use a spin coater to evenly coat a layer of zinc acetate on the substrate , ethanol mixed film, the specific spin-coating process is as follows: first, use a dropper to drop 4 drops of mixed solution A on the substrate, and then use a spin coater to rotate ...

Embodiment 2

[0043] A method for preparing an ultraviolet photodetector based on ZnO nanogrids, comprising the following steps:

[0044] (1) Preparation of a mixed solution: prepare a mixed solution of zinc acetate and ethanol at a ratio of 0.1g:30mL, and stir for 60min using a magnetic stirrer to obtain a mixed solution A of zinc acetate and ethanol, then, zinc acetate, zinc carbonate , ethanol is configured mixed solution by the ratio of 0.1g:0.035g:30mL; And use magnetic stirrer to stir 60min, obtain the mixed solution B of zinc acetate, zinc carbonate, ethanol;

[0045] (2) Preparation of thin film C: use one of glass, quartz, silicon wafer, sapphire, and metal plate as the substrate. The substrate size is 5cm×5cm. Use a spin coater to evenly coat a layer of zinc acetate on the substrate , ethanol mixed film, the specific spin-coating process is as follows: first, use a dropper to drop 10 drops of mixed solution A on the substrate, and then use a spin coater to rotate the substrate at ...

Embodiment 3

[0054] A method for preparing an ultraviolet photodetector based on ZnO nanogrids, comprising the following steps:

[0055] (1) Preparation of mixed solution: Zinc acetate and ethanol are prepared in the ratio of 0.15g:30mL mixed solution, and use magnetic stirrer to stir for 60min, obtain the mixed solution A of zinc acetate and ethanol, then, zinc acetate, zinc carbonate , ethanol is configured mixed solution by the ratio of 0.15g:0.035g:30mL; And use magnetic stirrer to stir 60min, obtain the mixed solution B of zinc acetate, zinc carbonate, ethanol;

[0056] (2) Preparation of thin film C: use one of glass, quartz, silicon wafer, sapphire, and metal plate as the substrate, the substrate size is 8cm×8cm, and evenly coat a layer of zinc acetate on the substrate using a spin coater , ethanol mixed film, the specific spin-coating process is as follows: first, use a dropper to drop 10 drops of mixed solution A on the substrate, and then use a spin coater to rotate the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com