Alkane dehydrogenation catalyst regeneration method and alkane dehydrogenation catalyst regeneration apparatus

A regeneration device, a technology for alkane dehydrogenation, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult disposal of waste catalysts, environmental pollution, etc. Safety and the effect of strengthening internal circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

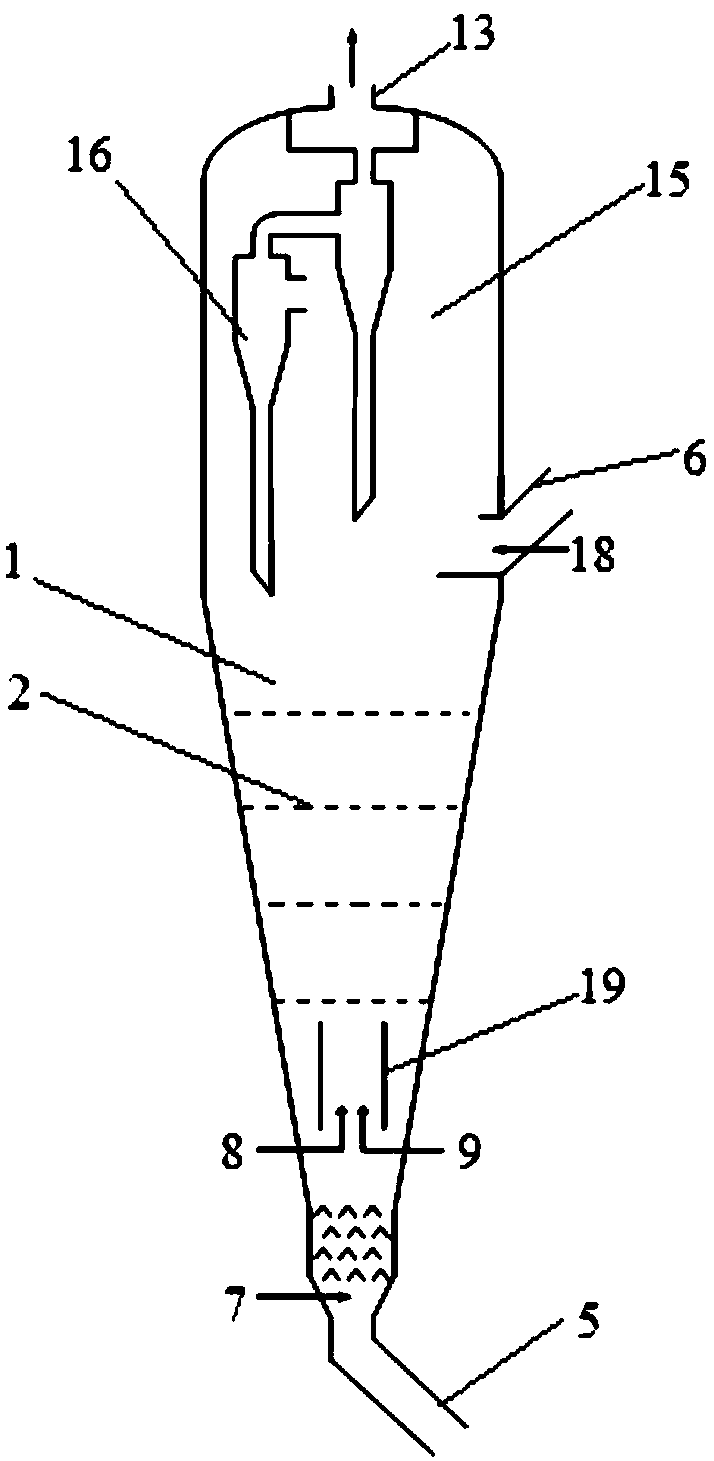

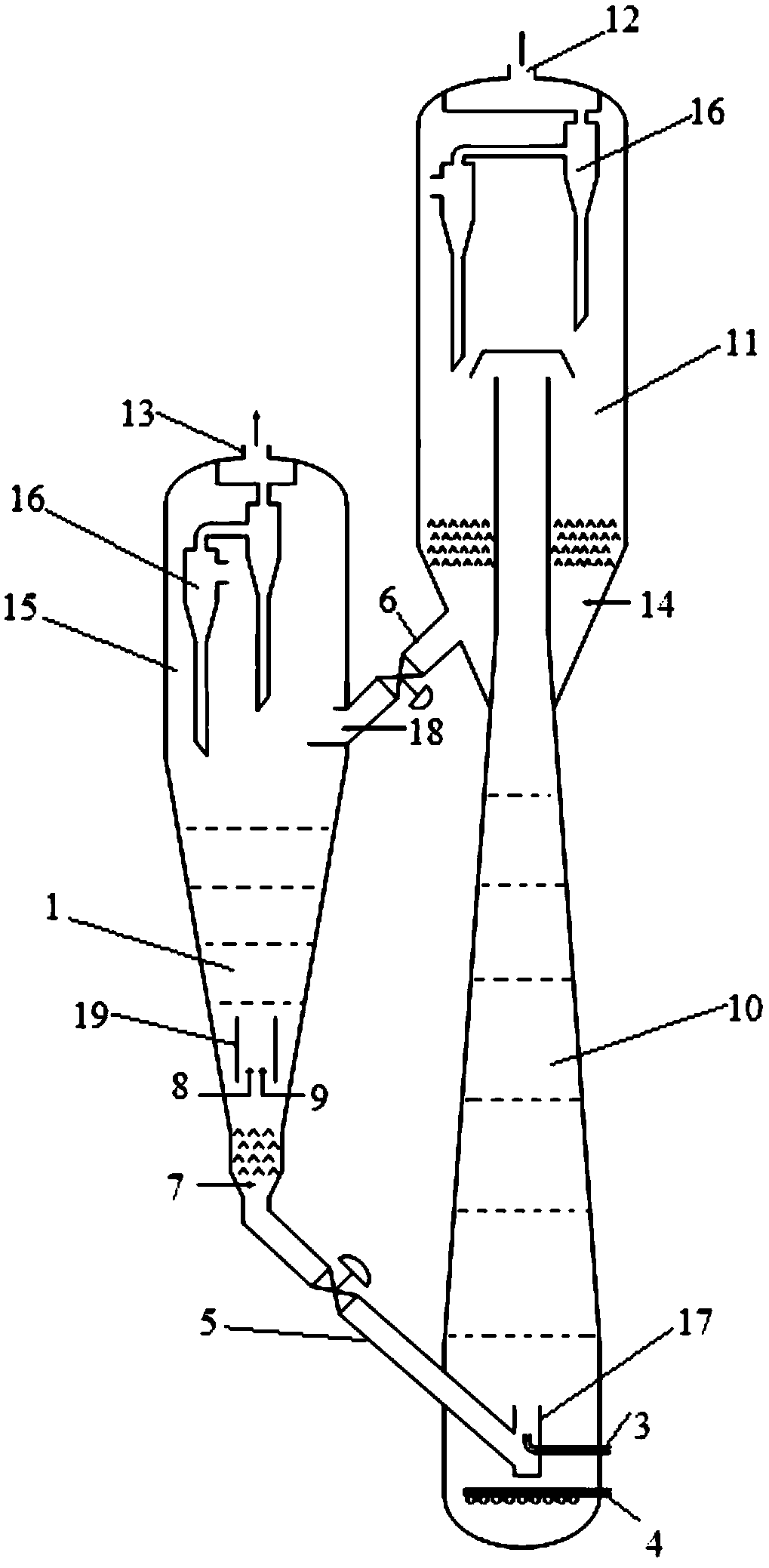

[0060] Using the inverted table regenerator of the present invention (that is, the cross-sectional diameter of the regenerator gradually increases from the bottom to the top), the height of the dense bed is 8m, the apparent gas velocity at the bottom is 0.8m / s, and the top of the dense bed is apparent The gas velocity is 0.1m / s, and there is no sleeve at the bottom of the bed. The ratio of air to natural gas is calculated based on the complete combustion of natural gas, and the excess oxygen is 2vol%. The bottom temperature of the dense catalyst bed was 680°C, the top temperature was 705°C, and the dilute phase temperature of the regenerator was 713°C. The CO content in the flue gas is 0.35 vol%.

Embodiment 2

[0062] Using the inverted table regenerator of the present invention (that is, the cross-sectional diameter of the regenerator gradually increases from the bottom to the top), the height of the dense bed is 8m, the apparent gas velocity at the bottom is 0.8m / s, and the top of the dense bed is apparent The gas velocity is 0.1m / s. A sleeve is set at the bottom of the bed, the average apparent gas velocity in the sleeve is 4m / s, and the height of the sleeve is 2m. The ratio of air to natural gas is calculated based on the complete combustion of natural gas, and the excess oxygen is 2vol%. Under these conditions, the bottom temperature of the dense catalyst bed was 693°C, the top temperature was 701°C, and the dilute phase temperature of the regenerator was 707°C. The CO content in the flue gas is 0.12vol%.

[0063] It can be seen that the sleeve is more conducive to the full combustion of the fuel, and has the effect of promoting the internal circulation of the catalyst and furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com