Waste treatment process

A technology of waste treatment and process, applied in the direction of microbial treatment, biological organic part treatment, application, etc., can solve the problems of inability to realize resource recycling, environmental pollution, etc., and achieve the effect of saving resources and costs, high quality, and increasing beneficial components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

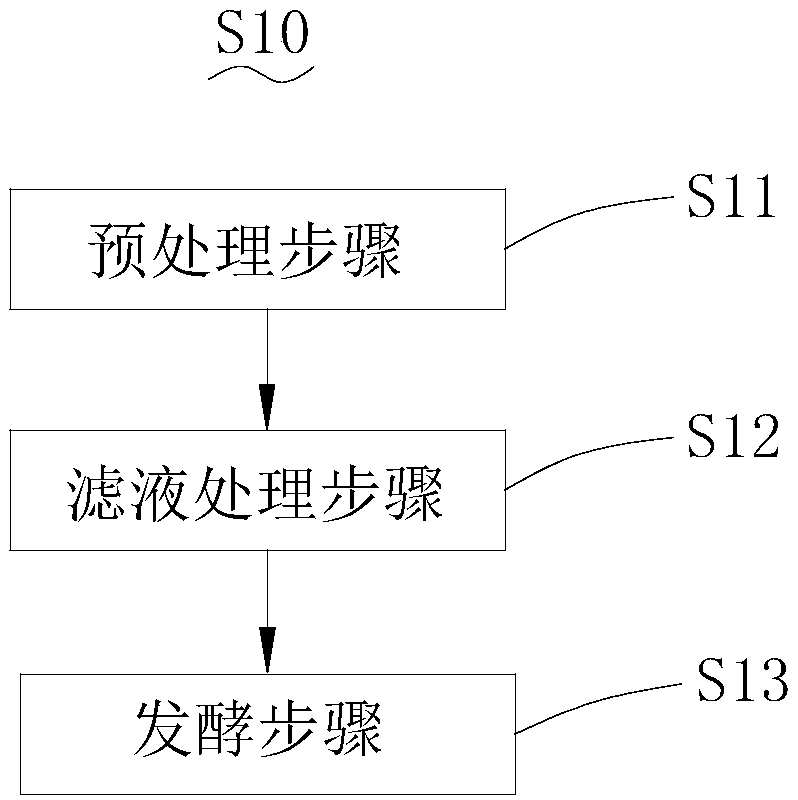

[0034] see figure 1 , Embodiment 1 of the present invention provides a garbage treatment process S10, comprising the following steps:

[0035] Pretreatment step S11, sorting the garbage, sorting out the garbage containing 15%-20% non-dissolved organic matter, and collecting the filtrate leached from the garbage during the sorting process;

[0036] Filtrate processing step S12, the filtrate is left to stand for stratification, the oil in the upper layer of the filtrate is adsorbed by an lipophilic component, and a suction device is arranged above the lipophilic component to extract the grease in the lipophilic component , collecting the water in the lower layer of the filtrate for use in garbage fermentation and humidification;

[0037] Fermentation step S13, naturally fermenting the garbage containing 15%-20% non-dissolved organic matter to obtain the fermentation intermediate product, adding a spray containing probiotic strains to the fermentation intermediate product to car...

Embodiment 2

[0079] see Figure 4 , Embodiment 2 of the present invention provides a garbage filtrate treatment system 10, including a filtrate collection tank 11 for collecting garbage filtrate, an oil-water separation tank 11 arranged on one side of the filtrate collection tank 11 and communicated with the filtrate collection tank 11 Pool 12, the oil removal device 13 that is arranged on the top of the oil-water separation pool 12 for removing grease in the garbage filtrate, and the buffer pool 14 that is arranged on one side of the oil-water separation pool 12 and communicates with the oil-water separation pool. The degreasing device 13 includes an oleophilic component 131 arranged on the top of the oil-water separation pool 12 for absorbing grease and a lipophilic component 131 arranged on the top of the oleophilic component 131 for extracting the grease in the oleophilic component. Suction device 132 .

[0080] In this design mode, by setting the lipophilic component 131 for absorbin...

Embodiment 3

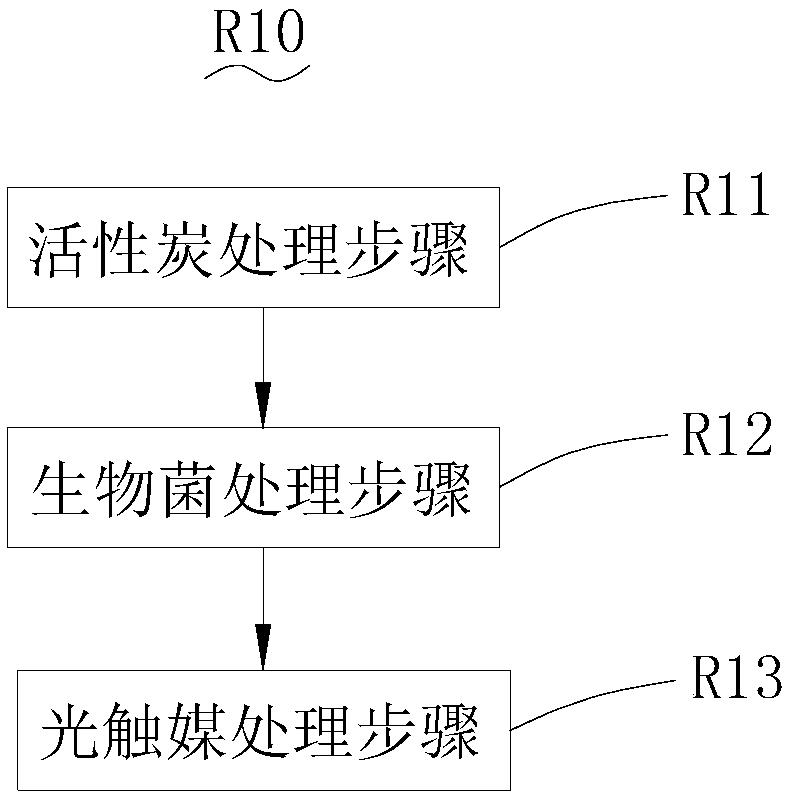

[0088] see Figure 5 and Figure 6 , Embodiment 3 of the present invention provides an exhaust gas purification plant 20 for purifying waste gas of a garbage treatment plant. The exhaust gas purification plant 20 includes:

[0089] The activated carbon adsorption bin 21, the activated carbon adsorption bin 21 includes a first compartment 211 and an activated carbon layer 212 disposed in the first compartment 211 to separate the first compartment 211 into a first compartment 2111 and a second compartment 2112;

[0090] Biological sterilization and deodorization bin 22, biological sterilization and deodorization bin 22 includes the second bin 221 and the organisms arranged in the second bin 221 to separate the second bin 221 into a third compartment 2211 and a fourth compartment 2212 The bacteria layer 222, the third compartment 2211 communicates with the second compartment 2112;

[0091] Photocatalyst decomposition bin 23, photocatalyst decomposition bin 23 comprises the 3rd ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com