PVC waterborne acrylate nanometer coating layer emulsion

A water-based acrylate and nano-coating technology, applied in the coating and other directions, can solve the problems of high cost of water-based polyurethane, environmental pollution of solvent-based pressure-sensitive adhesives, poor adhesion of water-based primers, etc. The effect of hardness and surface sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

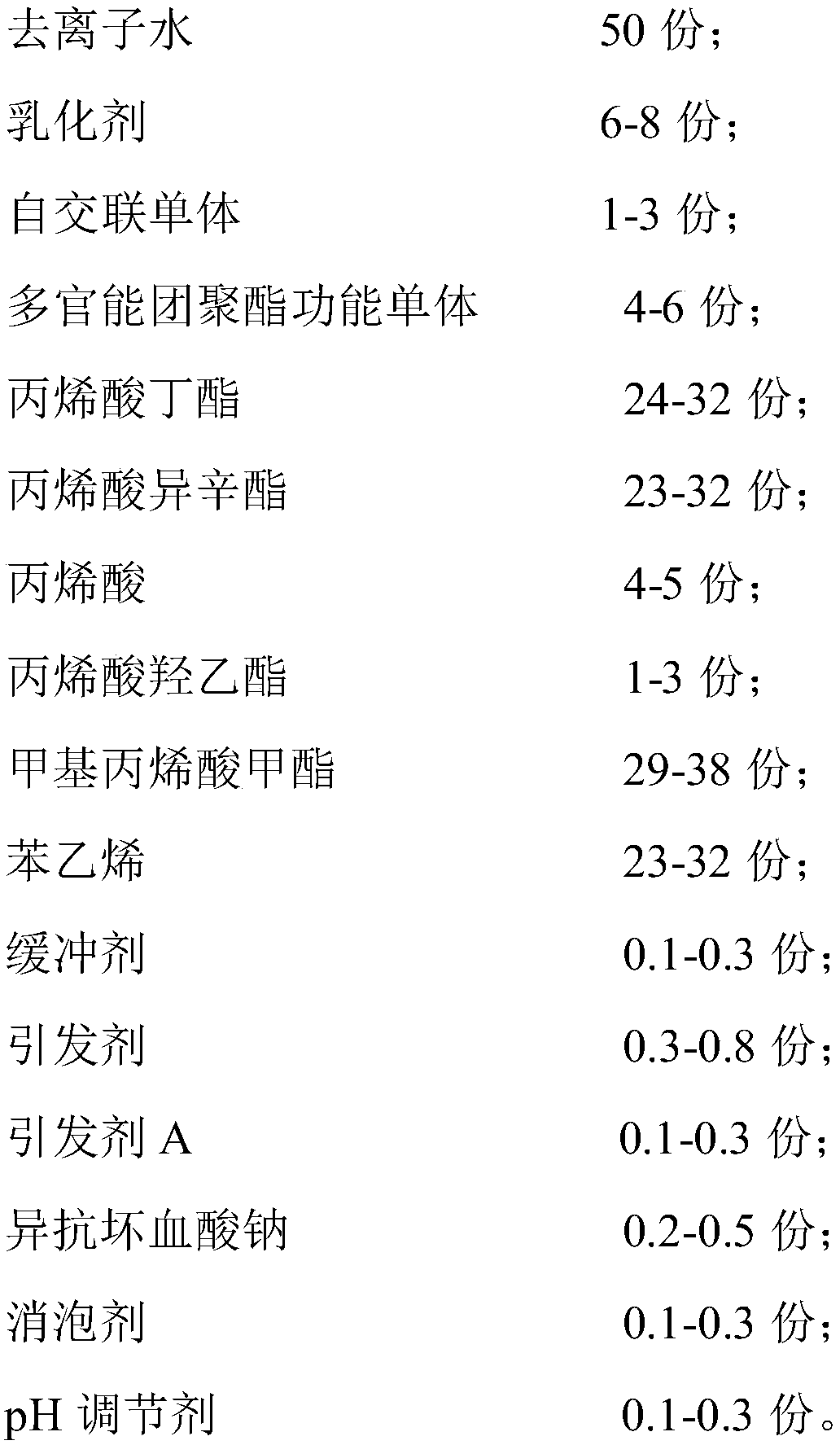

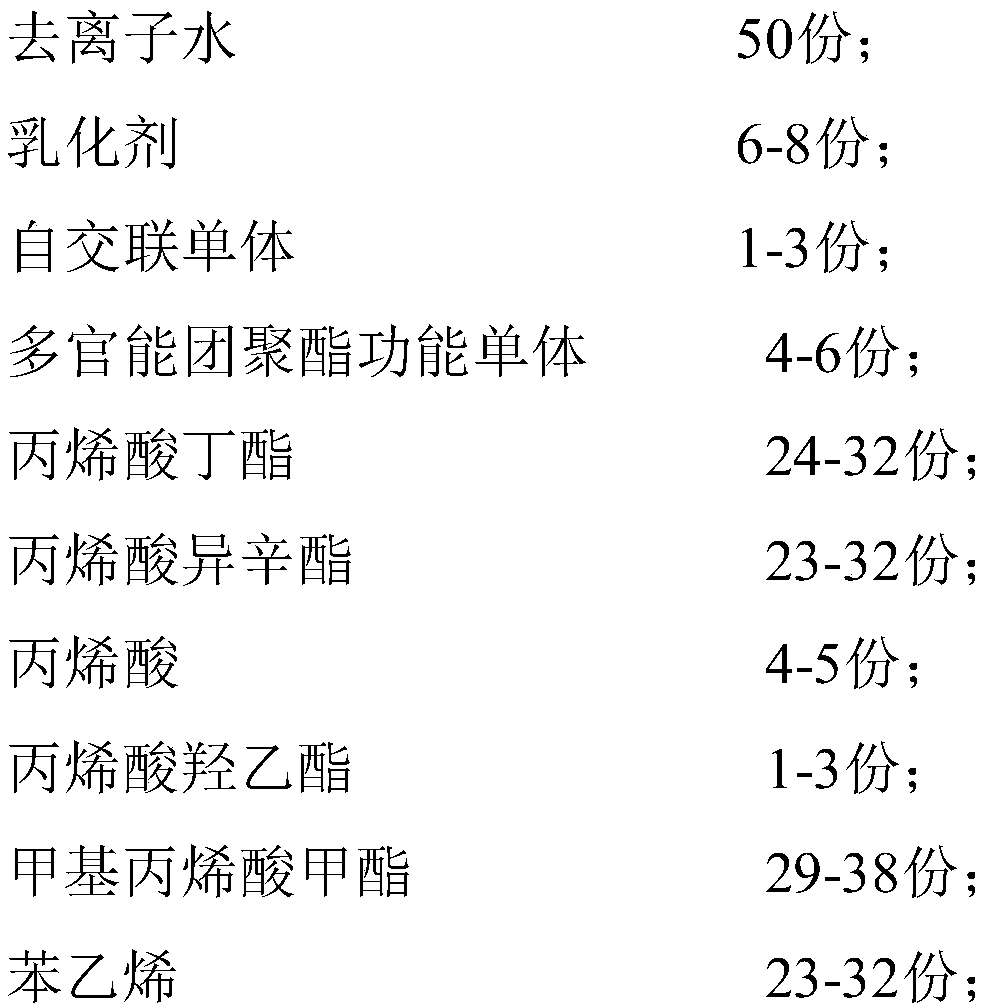

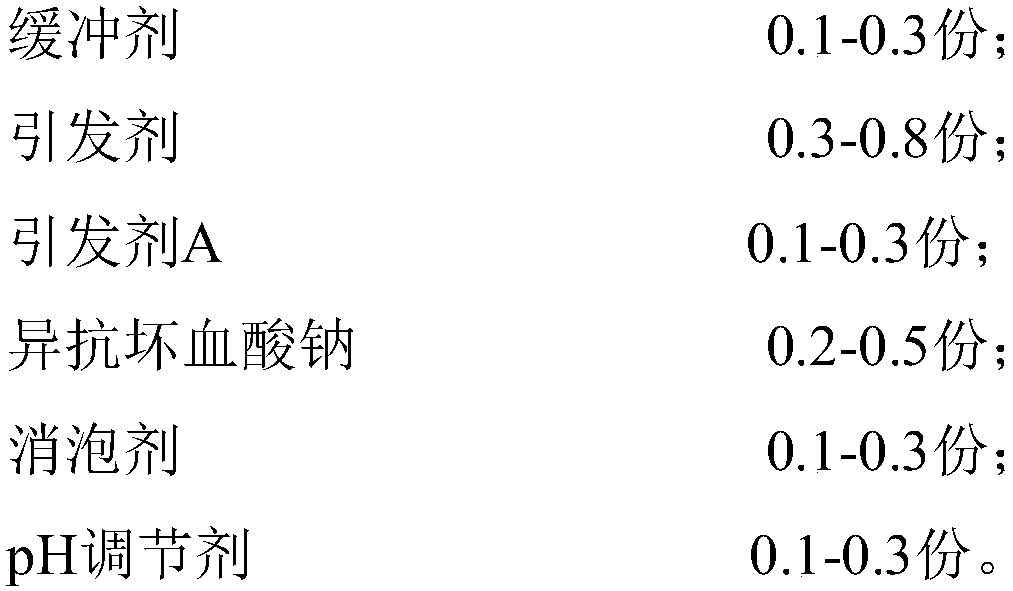

[0024] Add 200mL deionized water into a 1000ML four-neck flask, start stirring, set the speed at 200rpm, and start heating. Add 30% deionized water to the pre-emulsification bottle, add 54g reactive emulsifier SR-10, 10g self-crosslinking monomer, 40g multifunctional polyester functional monomer, 240g butyl acrylate, 230g isooctyl acrylate while stirring , 40g acrylic acid, 10g hydroxyethyl acrylate, 290g methyl methacrylate, 230g styrene, stirred at high speed for 1 hour, and prepared the pre-emulsion for subsequent use; continue to heat the four-necked flask, and when the temperature of the four-necked flask rose to 80 degrees Celsius, Add 6g of reactive emulsifier and 1g of ammonium bicarbonate. When the temperature reaches 84 degrees Celsius, take 2% pre-emulsion and put it into a four-necked flask. Then add 1.2g of ammonium persulfate, until light blue appears in the four-necked flask, and the temperature is now stable at 85 degrees Celsius. Start to add the remaining pr...

Embodiment 2

[0026] Add 200mL deionized water into a 1000ML four-neck flask, start stirring, set the speed at 200rpm, and start heating. Add 30% deionized water to the pre-emulsification bottle, add 63g reactive emulsifier SR-10, 20g self-crosslinking monomer, 50g multifunctional polyester functional monomer, 280g butyl acrylate, 280g isooctyl acrylate while stirring , 45g acrylic acid, 20g hydroxyethyl acrylate, 330g methyl methacrylate, 280g styrene, stirred at high speed for 1 hour, and prepared the pre-emulsion for subsequent use; continue to heat the four-necked flask, and when the temperature of the four-necked flask rose to 80 degrees Celsius, Add 7g reactive emulsifier and 2g ammonium bicarbonate. When the temperature reaches 84 degrees Celsius, take 3% pre-emulsion and put it into a four-necked flask. Then add 2g of ammonium persulfate, until light blue appears in the four-necked flask, and the temperature is now stable at 85 degrees Celsius. Start to add the remaining pre-emulsi...

Embodiment 3

[0028] Add 200mL deionized water into a 1000ML four-neck flask, start stirring, set the speed at 200rpm, and start heating. Add 30% deionized water to the pre-emulsification bottle, add 72g reactive emulsifier SR-10, 30g self-crosslinking monomer, 60g multifunctional polyester functional monomer, 320g butyl acrylate, 320g isooctyl acrylate 50g while stirring Acrylic acid, 30g hydroxyethyl acrylate, 380g methyl methacrylate, and 320g styrene were stirred at high speed for 1 hour to prepare a pre-emulsion for subsequent use; continue to heat the four-necked flask, and when the temperature of the four-necked flask rose to 80 degrees Celsius, 8g Reactive emulsifier, 3g ammonium bicarbonate is added, and when the temperature reaches 84 degrees Celsius, take 4% pre-emulsion and put it into a four-necked flask. Then add 3.2g of ammonium persulfate, until light blue appears in the four-necked flask, and the temperature is stable at 85 degrees Celsius. Start to add the remaining pre-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com