An environmentally friendly cigarette filter rod and a preparation method and application thereof

A cigarette filter rod, an environmentally friendly technology, applied in the application, e-liquid filter, tobacco and other directions, can solve the problems of difficulty in popularization and application, single form, single form, and single function of cigarette filter rod, and achieve more security. , good retention effect, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

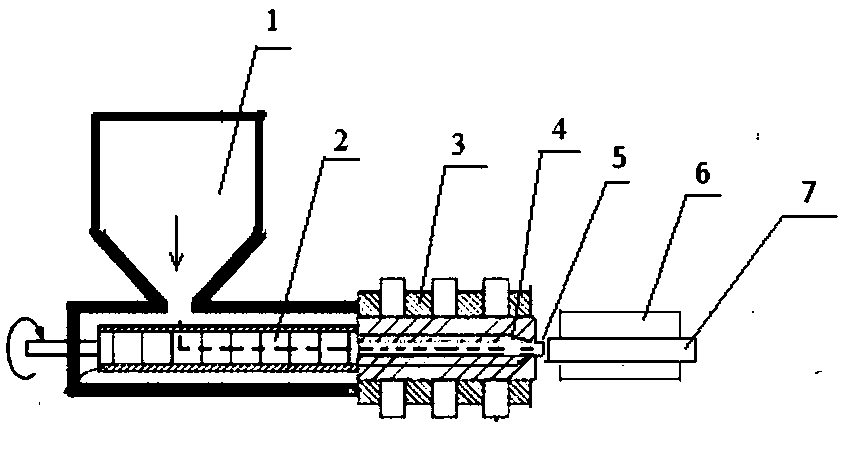

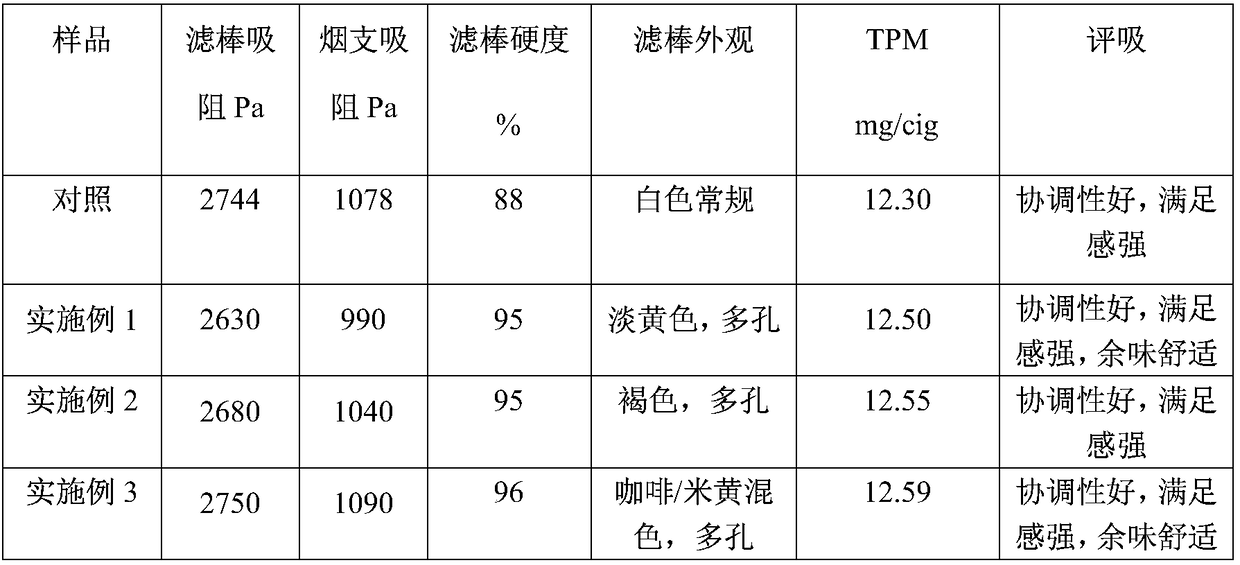

Embodiment 1

[0053] In this embodiment, a round rod forming device is used to prepare cigarette filter rods, and the round rod forming device is improved as follows on the basis of a conventional single-screw extruder: 1) the screw rod is a 20 equidistant screw rod, and the screw thread is a height of 4mm Toothed thread; the depth of the groove on the head thread of the screw is consistent with the height of the thread, and the width is 3mm. The head of the screw is provided with 4 sets of equidistant grooves; 2) the die with an inner diameter of 7.0mm is connected with A glass tube with an inner diameter of 7.5 mm, surrounded by an air-cooled cooler.

[0054] 1) Remove impurities from the corncobs, then cook, sterilize, sterilize and dry them in the sun; 2) grind the corncobs mechanically and screen out 30-50 mesh corncob particles, balance the moisture to 8% for later use; 3) mix the corncob particles with polyethylene The micropowder is mixed in an ultra-high-speed mixer according to th...

Embodiment 2

[0057] In this embodiment, a round rod forming device is used to prepare cigarette filter rods, and the round rod forming device is improved as follows on the basis of a conventional single-screw extruder: 1) the screw rod is a 20 equidistant screw rod, and the screw thread is a height of 4mm Toothed thread; the groove depth on the head thread of the screw rod is consistent with the height of the thread, and the width is 3mm, and 4 sets of equidistant grooves are provided on the screw head; 2) the die of 6.5mm inner diameter is connected with A glass tube with an inner diameter of 7.5 mm, surrounded by a water-cooled cooler.

[0058] 1) Remove impurities from the walnut shell rods, then cook, sterilize, sterilize, and dry them in the sun; 2) Mechanically crush and screen out 40-60 mesh walnut shell particles, and balance the water content to 8% for later use; 3) Mix the walnut shell particles with vinyl acetate The ester micropowder is mixed in an ultra-high-speed mixer accord...

Embodiment 3

[0060] In this embodiment, a round rod forming device is used to prepare cigarette filter rods, and the round rod forming device is improved as follows on the basis of a conventional single-screw extruder: 1) the screw rod is a 20 equidistant screw rod, and the screw thread is a height of 4mm Toothed thread, 4 sets of equidistant grooves are arranged on the head of the screw; the depth of the groove on the head thread of the screw is consistent with the height of the thread, and the width is 3mm; 2) the die with an inner diameter of 7.0mm is connected with A glass tube with an inner diameter of 7.5 mm, surrounded by an air-cooled cooler.

[0061] 1) Remove impurities from coffee husks and coconut husks, then cook, sterilize, and dry them in the sun; 2) Mechanically crush and screen out 20-80 mesh coffee husks and coconut husk powders, and balance the moisture to 10% for use; 3) Mix the above-mentioned coffee shell and coconut shell powder evenly at a mass ratio of 2:1 to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com