Filter bag for water treatment

A filter bag and water treatment technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of slow filtration speed, difficult to remove small particles, and single filtration method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

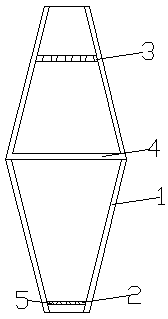

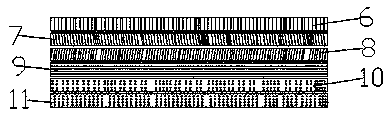

[0022] Such as figure 1 and figure 2 As shown, a filter bag for water treatment, the entire filter bag can be made of air-permeable or air-impermeable materials, such as metal material or ordinary filter cloth. The filter bag 1 is a hollow barrel-shaped structure, the inner diameter of the filter bag 1 gradually increases from both sides to the middle, and the filtering speed can be preliminarily and automatically adjusted through the change of the caliber. The openings at both ends of the filter bag 1 are provided with a first filter layer 2 and a second filter layer 3, a third filter layer 4 is provided in the middle of the filter bag 1, and evenly distributed on the first filter layer 2 and the second filter layer 3 A plurality of water outlet holes 5, the apertures of the water outlet holes 5 gradually increase from top to bottom. Since the diameters of the two ports of the filter bag 1 are relatively small, the water flow from the upper part of the filter bag 1 enters a...

Embodiment 2

[0031] A filter bag for water treatment, the difference from embodiment 1 is that the core material is made of composite fiber.

[0032] The composite fiber is to combine nano-activated carbon particles and PS, and prepare activated carbon / PS composite fiber by electrospinning technology. The mass ratio of activated carbon / PS is 2-3:35-38, the spinning voltage is 15-19kV, and the composite fiber average The diameter is 1339-1345nm.

[0033] The antistatic coating is sprayed with carbon black / polyurethane spray particles prepared by electrostatic spraying technology. The optimum mass fraction of carbon black / polyurethane is 9%, the spraying voltage is 26kV, and the average particle size is 400nm.

[0034] The adsorption coating is activated carbon / polyurethane spray particles prepared by electrostatic spraying technology. The optimal mass fraction of activated carbon / polyurethane is 9%, the spraying voltage is 25kV, and the average particle size is 300nm.

[0035] The warp yar...

Embodiment 3

[0039] A filter bag for water treatment, the difference from embodiment 2 is that the core material is made of composite fiber. The composite fiber is carbon black / PS composite fiber prepared by electrospinning technology, the optimum mass ratio of carbon black / PS is 1-2:20-22, the spinning voltage is 19-20kV, and the average fiber diameter is 1372-1376nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com