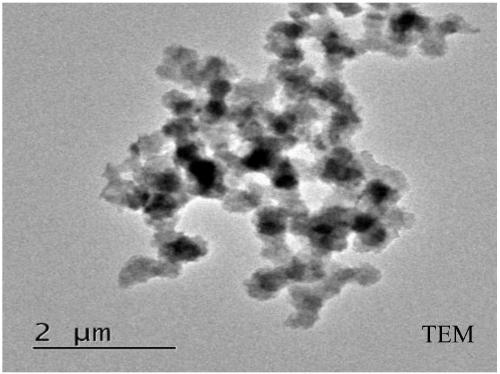

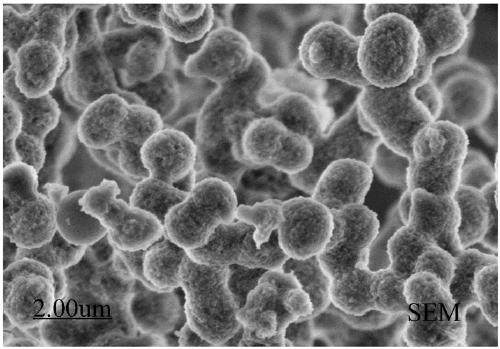

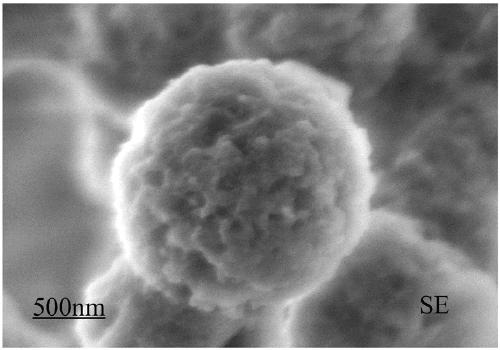

Preparation method of mesoporous cobalt-system carbon-silicon nanosphere Fenton catalyst and mesoporous cobalt-system carbon-silicon nanosphere Fenton catalyst and application thereof

A catalyst, carbon-silicon technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor activity, low stability, low utilization rate, etc. Stable, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of the first mixed solution step: take 0.2g / L soluble cobalt compound aqueous solution (wherein, the soluble cobalt compound aqueous solution is cobalt nitrate solution) 100ml and mix with 10g / L CTAB ethanol solution 30ml, stir for 15min, and continue stirring for 1.5h Add organosilicon solvent (wherein, organosilicon solvent is tetramethyl orthosilicate). After the organosilicon solvent is added, the calculated ratio of the amount of Si element in the organosilicon solvent to the amount of Co element in the soluble cobalt compound is 25:1. Then, 3 ml of aqueous ammonia having a mass fraction of 8% was added dropwise to the mixed system, and stirred for 24 hours while adding the aqueous ammonia dropwise, to obtain a first mixed solution.

[0041] The step of preparing the solid product: transfer the first mixed solution to a constant temperature water bath at 65° C. and stir for 0.5 h at a stirring speed of 600 r / min. The stirred first mixed solution was th...

Embodiment 2

[0044] Step of preparing the first mixed solution: take 100ml of 0.4g / L soluble cobalt compound aqueous solution (wherein, the soluble cobalt compound aqueous solution is cobalt sulfate solution) and mix with 100ml of 18g / L CTAB ethanol solution, stir for 2min, and continue stirring for 2.5h Add organosilicon solvent (wherein, organosilicon solvent is methyl silicone oil). After the organosilicon solvent is added, the calculated ratio of the amount of Si element in the organosilicon solvent to the amount of Co element in the soluble cobalt compound is 50:1. Add 5ml of aqueous ammonia with a mass fraction of 10% dropwise to the mixed system, and stir for 16 hours while adding the aqueous ammonia dropwise to prepare the first mixed solution.

[0045] The step of preparing the solid product: transfer the first mixed solution to a constant temperature water bath at 70° C. and stir for 1.5 h at a stirring speed of 550 r / min. The stirred first mixed solution was then transferred to...

Embodiment 3

[0048] Step of preparing the first mixed solution: take 100ml of 0.53g / L soluble cobalt compound aqueous solution (wherein the soluble cobalt compound aqueous solution is cobalt chloride solution) and mix with 75ml of 15g / L CTAB ethanol solution, stir for 7min, and continue stirring for 3h Add organosilicon solvent (wherein, organosilicon solvent is tetraethyl orthosilicate). After the organosilicon solvent is added, the calculated ratio of the amount of Si element in the organosilicon solvent to the amount of Co element in the soluble cobalt compound is 100:1. Then, 8 ml of aqueous ammonia having a mass fraction of 12% was added dropwise to the mixed system, and stirred for 8 hours while adding the aqueous ammonia dropwise, to obtain a first mixed solution.

[0049] The step of preparing the solid product: transfer the first mixed solution to a 75°C constant temperature water bath and stir for 0.75h at a stirring speed of 450r / min. The stirred first mixed solution was then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com