Bifunctional mixed-type polyacid-based composite material, preparation method and application thereof

A composite material and functional technology, applied in the field of photocatalytic materials, achieves the effects of simple preparation process, cheap and easy-to-obtain synthetic raw materials, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

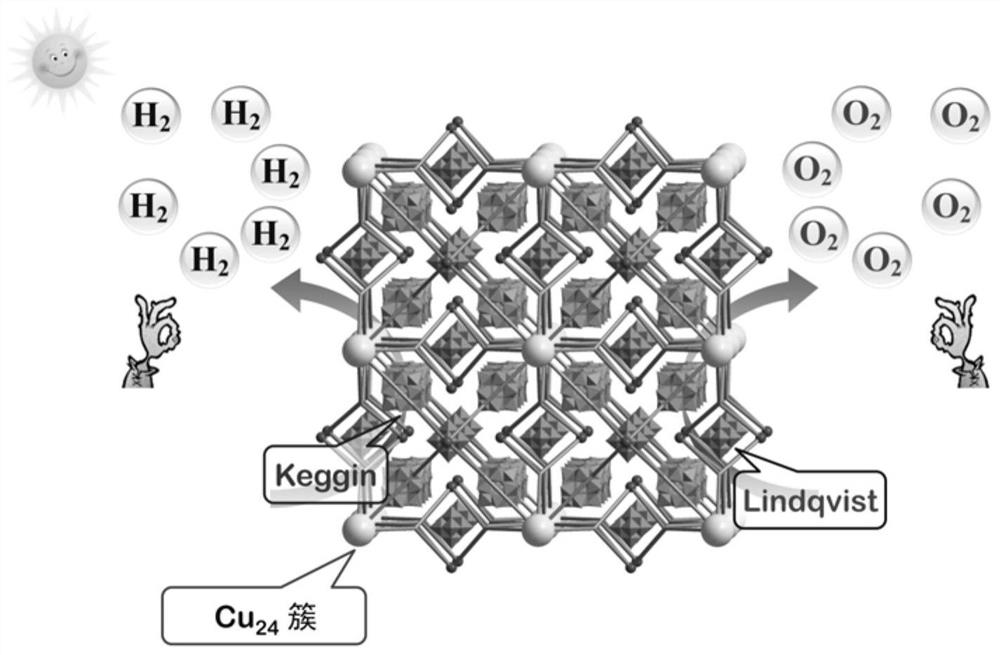

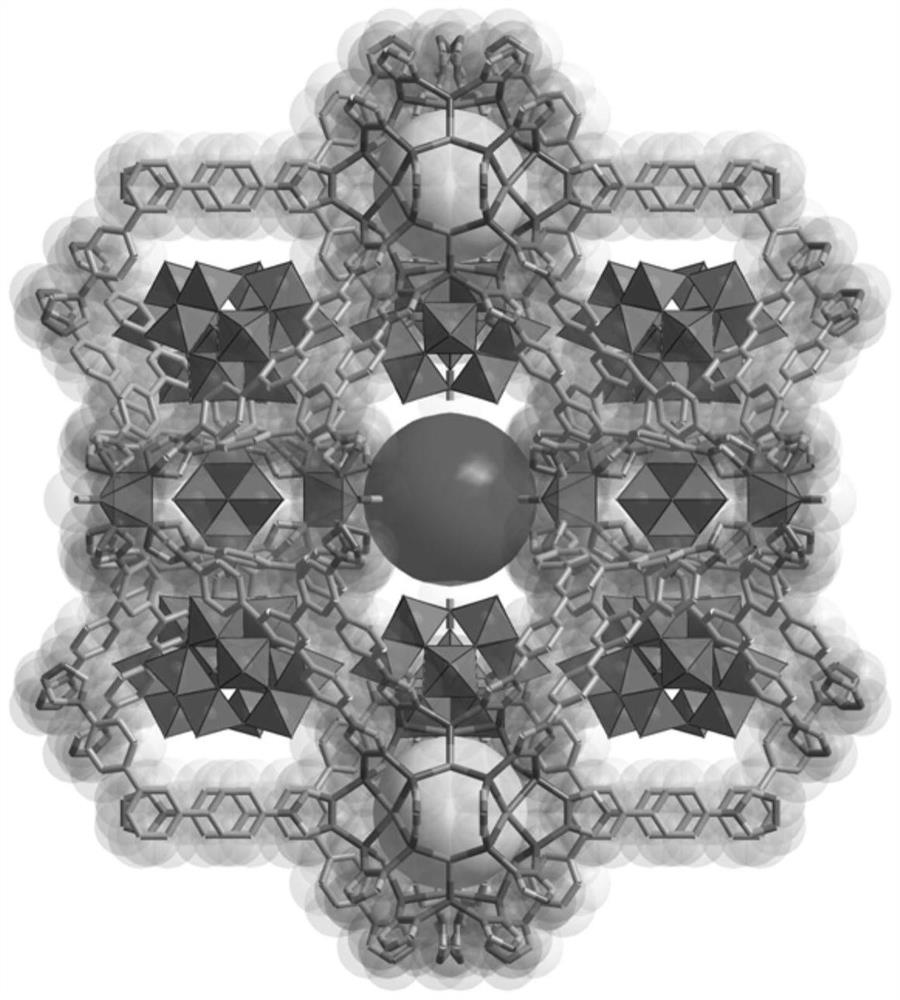

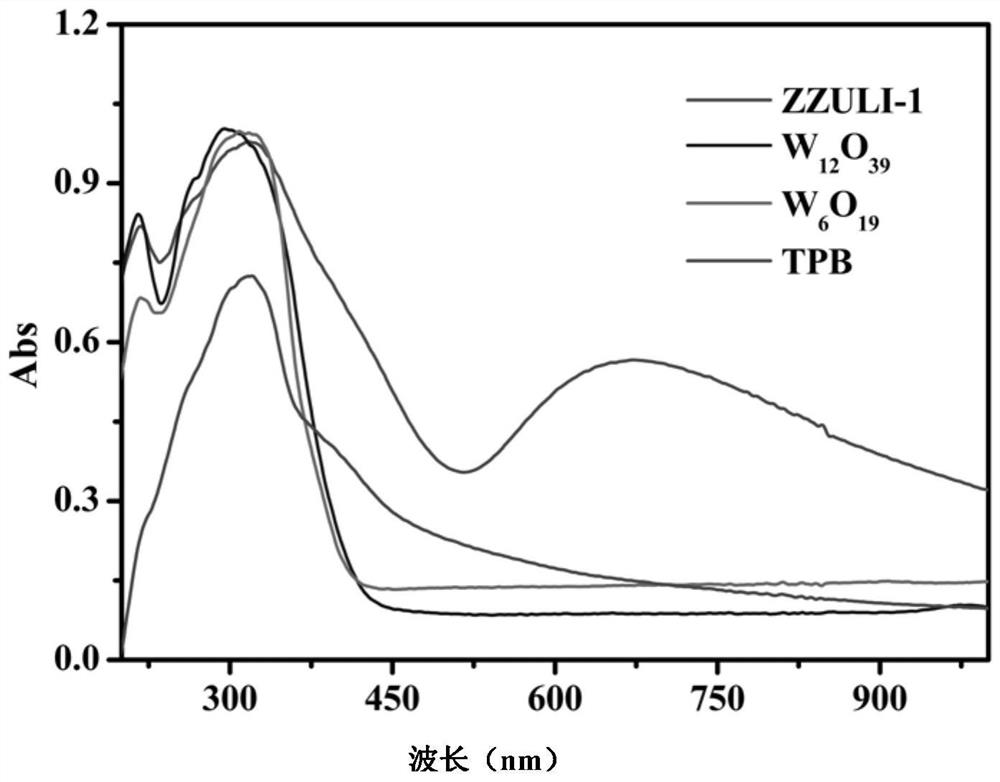

[0036] Another aspect of the embodiment of the present invention also provides the bifunctional hybrid polyacid-based composite material and its preparation method, which includes: adding polymetallic acid with a molar ratio of 2:40:1 to 2:40:3 Oxygenate, copper salt and TPB ligand are fully mixed in a solvent, and then solidified at 110-130°C for 48-72 hours to obtain dark green blocky crystals, which are the bifunctional mixed polyacid complex Material.

[0037] Further, the copper salt includes copper chloride dihydrate, but is not limited thereto.

[0038] Further, the solvent includes any one or a combination of two or more of DMF, acetonitrile and methanol, but is not limited thereto.

[0039] Further, the polyoxometalates include (TBA) 4 [W 10 o 32 ], but not limited to this.

[0040] In some specific embodiments, the preparation method includes: combining copper salt, TPB ligand and polyoxometalate (TBA) 4 [W 10 o 32 ] mixed evenly to obtain the mixture, and th...

Embodiment 1

[0051] Example 1: Preparation of bifunctional hybrid polyacid-based composite material

[0052] Will (TBA) 4 [W 10 o 32 ] (33.2mg, 0.01mmol), CuCl 2 2H 2O (34.1mg, 0.20mmol) and TPB (2.5mg, 0.005mmol) were added to a mixture of N,N-dimethylformamide (DMF, 2.0mL), acetonitrile (4.0mL) and methanol (0.25mL) For stirring, use 1.0mol·L –1 HCl adjusted the pH of the system to 2.3, stirred at room temperature for 30 minutes, then added the above suspension into a 25mL polytetrafluoroethylene reactor, baked at 120°C for 72 hours, and finally cooled to room temperature to obtain dark green Blocky crystals were washed 3 times with DMF and dried at room temperature. The yield was about 56%.

Embodiment 2

[0053] Example 2: Preparation of bifunctional hybrid polyacid-based composite material

[0054] Will (TBA) 4 [W 10 o 32 ] (33.2mg, 0.01mmol), CuCl 2 2H 2 O (34.1mg, 0.20mmol) and TPB (7.5mg, 0.015mmol) were added to a mixture of N,N-dimethylformamide (DMF, 1.0mL), acetonitrile (4.0mL) and methanol (0.5mL) For stirring, use 1.5mol·L –1 HCl adjusted the pH of the system to 2.1, stirred at room temperature for 40 minutes, then added the above suspension into a 25mL polytetrafluoroethylene reactor, baked at 110°C for 60 hours, and finally cooled to room temperature to obtain dark green Blocky crystals were washed 3 times with DMF and dried at room temperature. The yield was about 53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com