A kind of preparation method of silver-nickel-zinc oxide electrical contact alloy

A technology of silver zinc oxide and zinc oxide, applied in silver compounds, silver compounds, chemical instruments and methods, etc., can solve the problem of poor processing performance and welding performance, poor welding resistance and arc erosion resistance of AgNi contacts, etc. problems, to achieve the effect of easy processing and molding, reducing the amount of silver used, and avoiding easy pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

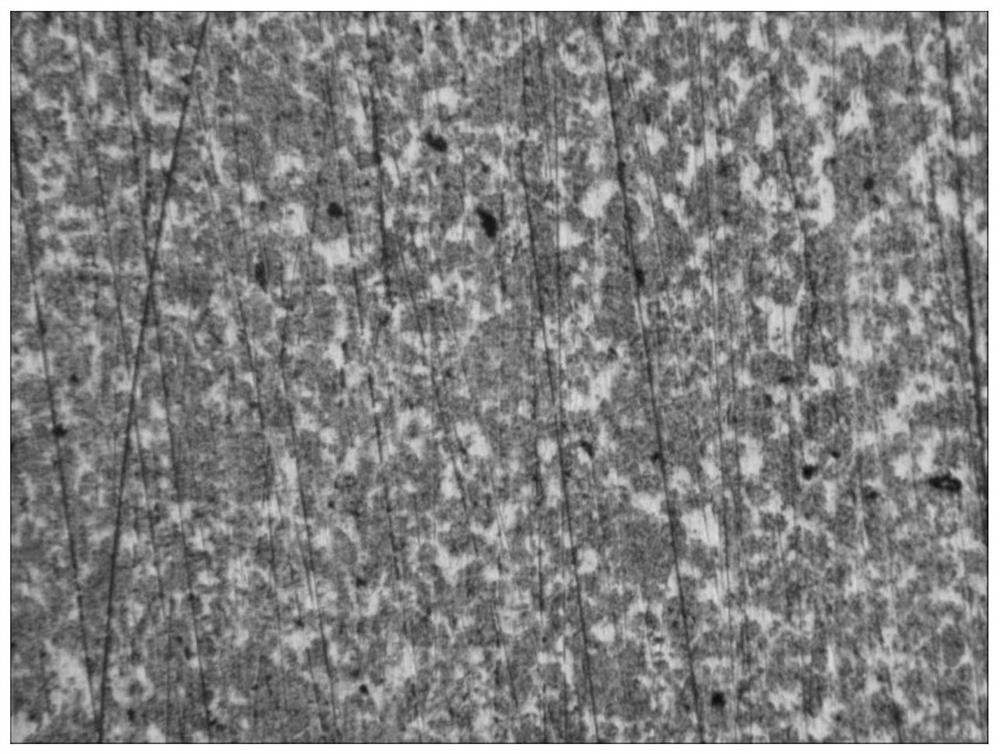

Image

Examples

preparation example Construction

[0025] A preparation method of a silver-nickel-zinc oxide electrical contact alloy of the present invention is specifically implemented according to the following steps:

[0026] Step 1. Preparation of Zn(NO 3 ) 2 and AgNO 3 mixed solution A;

[0027] First add Zn powder to HNO with a mass fraction of 50% to 65% 3 fully dissolved in the solution to obtain 1.5mol / L Zn(NO 3 ) 2 solution; then Zn(NO 3 ) 2 The solution was slowly added to 1.5mol / L AgNO 3 In aqueous solution, mixed solution A was obtained.

[0028] Step 2, adding a polyvinylpyrrolidone solution as a dispersing agent to the mixed solution A, and after stirring evenly, dropwise adding an ascorbic acid solution to it as a reducing agent, and stirring continuously to obtain a mixed solution B;

[0029] The concentration of the polyvinylpyrrolidone solution is 0.2-0.8 mol / L, and the concentration of ascorbic acid is 1-2 mol / L.

[0030] Step 3, adding ammonia water dropwise to the mixed solution B and adjusting...

Embodiment 1

[0041] Step 1. First add Zn powder to HNO with a mass fraction of 50% 3 fully dissolved in the solution to obtain 1.5mol / L Zn(NO 3 ) 2 solution; then Zn(NO 3 ) 2 The solution was slowly added to 1.5mol / L AgNO 3 In the aqueous solution, mixed solution A is obtained;

[0042] Step 2. The mixed solution A is magnetically stirred at 55°C for 2 hours, and 50 ml of a 0.4 mol / L polyvinylpyrrolidone solution is added dropwise to the mixed solution A as a dispersant within the first 30 minutes of stirring. The ascorbic acid solution of 1mol / L was added thereto as a reducing agent, and was continuously stirred to obtain mixed solution B;

[0043] Step 3. The mixed solution B was subjected to ultrasonic stirring at 40°C for 30 minutes, and during the process, the pH value of the solution was adjusted to 9 by dropwise addition of ammonia water. After the dropwise addition was completed, a magnetic stirrer was used to stir for 0.5 hours until the precipitation was complete. , to obta...

Embodiment 2

[0049] Step 1. First add Zn powder to HNO with a mass fraction of 60% 3 fully dissolved in the solution to obtain 1.5mol / L Zn(NO 3 ) 2 solution; then Zn(NO 3 ) 2 The solution was slowly added to 1.5mol / L AgNO 3 In the aqueous solution, mixed solution A is obtained;

[0050] Step 2. The mixed solution A was magnetically stirred at 55 °C for 2 hours, and 50 ml of a 0.6 mol / L polyvinylpyrrolidone solution was added to the mixed solution A within the first 30 minutes, and then 1.5 mol / L of ascorbic acid solution was added to it. , and continuously stirred to obtain mixed solution B;

[0051] Step 3. The mixed solution B was subjected to ultrasonic stirring at 50° C. for 1 h, and during the process, the pH value of the solution was adjusted to 10 by dropwise addition of ammonia water, and then stirred for 30 min after the dropwise addition was completed, until the precipitation was complete, and a precipitated product was obtained;

[0052] Step 4. First put the precipitated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com