Method for inducing periodic surface structure of transparent dielectric material with single-pulse nanosecond laser

A technology of periodic structures and dielectric materials, applied in nanostructure manufacturing, specific nanostructure formation, nanotechnology, etc., can solve problems such as cracks and high surface roughness, achieve the effect of changing optical characteristics and realizing information sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

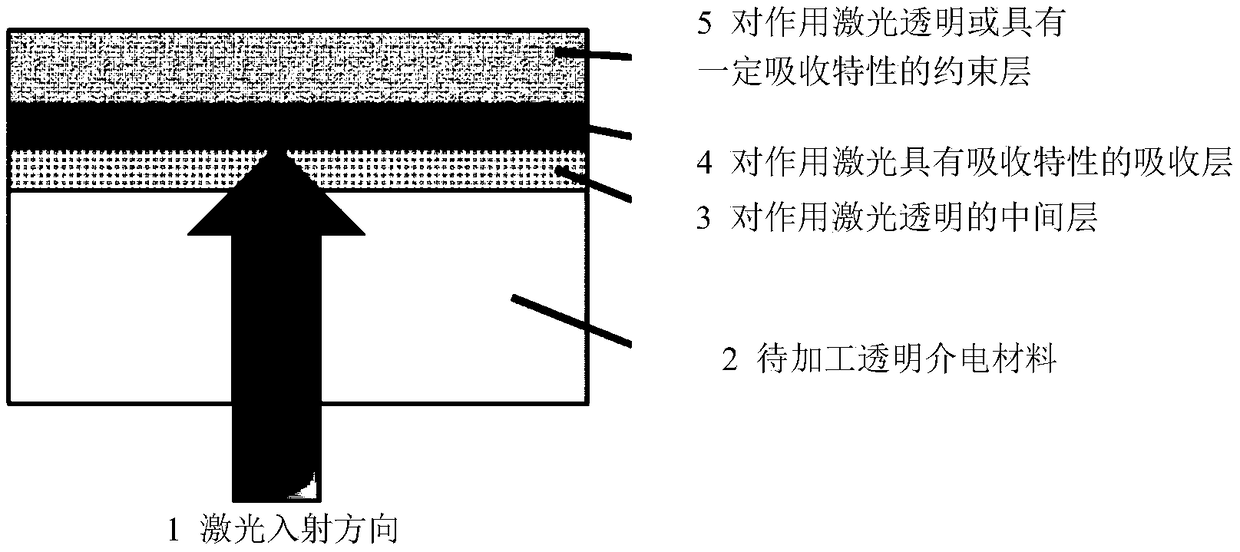

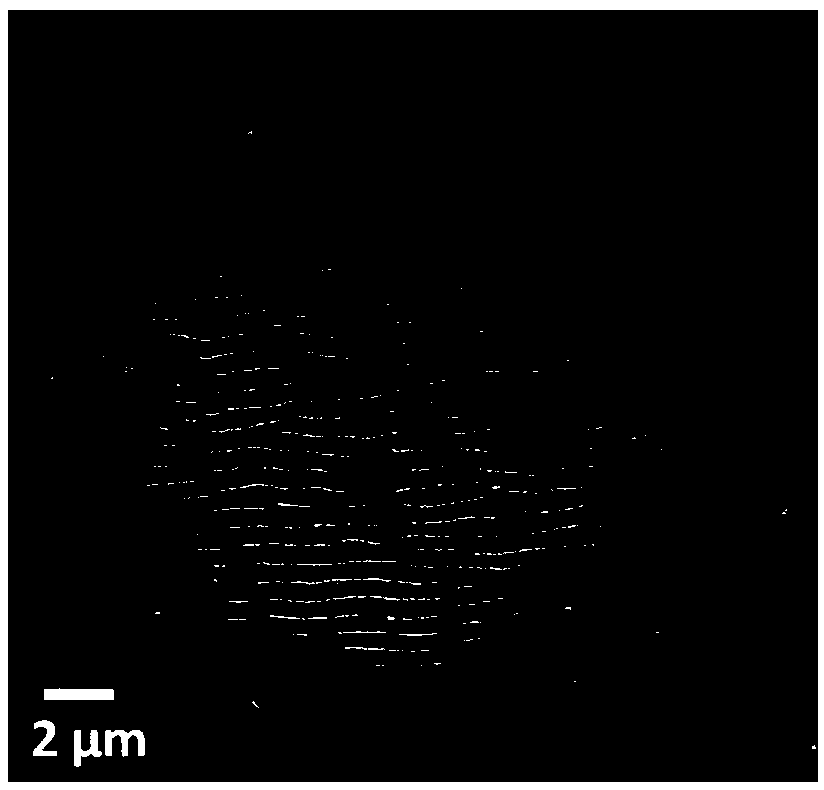

[0036] SiO 2 The etching process of LIPSS on the surface of the substrate is taken as an example to describe the technical solution of the present invention in detail.

[0037] (1) Using diameter 25cm, thickness 300μm, double-sided polished SiO 2 substrate.

[0038] (2) Spin-coating method on SiO 2 One side of the substrate was coated with a novolac resin (intermediate layer) in a thickness of 500 nm, followed by exposure to the novolak resin film and heating maintained at 150° C. for 1 minute to harden the novolak resin film. Finally, the novolac resin was etched to a thickness of 200 nm by Ar ion beam.

[0039] (3) A Cr film (absorbing layer) with a thickness of 100 nm was deposited on the surface of the novolac resin film by magnetron sputtering.

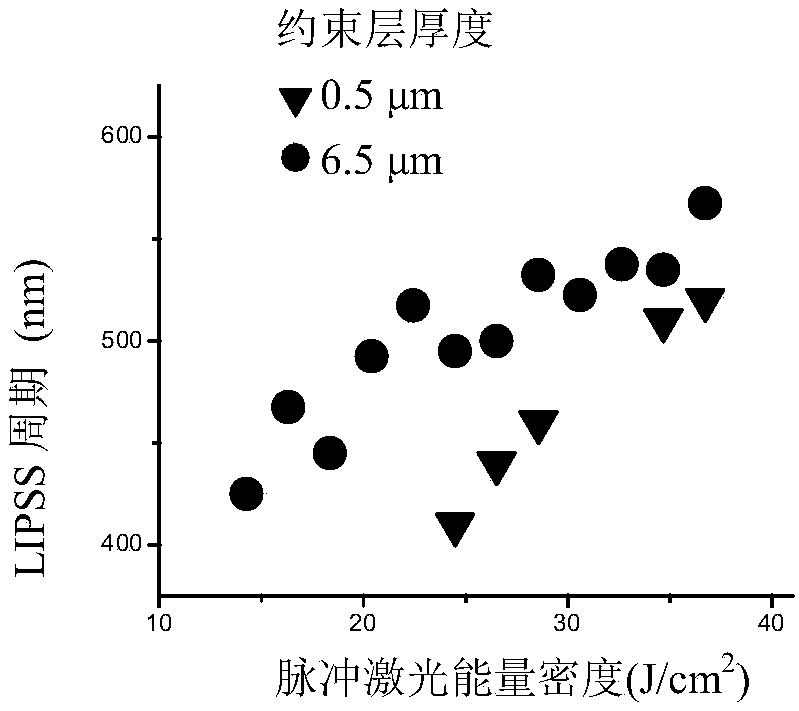

[0040] (4) Coating a 6.5 μm thick novolak resin film (constraint layer) on the surface of the Cr film by spin coating, then exposing the novolak resin film, and heating and maintaining it at 100° C. for 1 minute, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com