Method of multi-pulse picosecond laser-induced semiconductor material periodic surface structure

A periodic structure and picosecond laser technology, applied in the process of producing decorative surface effects, microstructure technology, microstructure devices, etc., can solve the problems of harsh environmental conditions, expensive equipment, and complicated steps of periodic structures , to achieve the effect of easy operation and maintenance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The technical scheme of the present invention is described in detail by taking the etching process of LIPSS on the surface of a Si substrate as an example.

[0027] (1) A Si substrate with a diameter of 2.5 cm and a thickness of 500 μm is used, which is polished on one side.

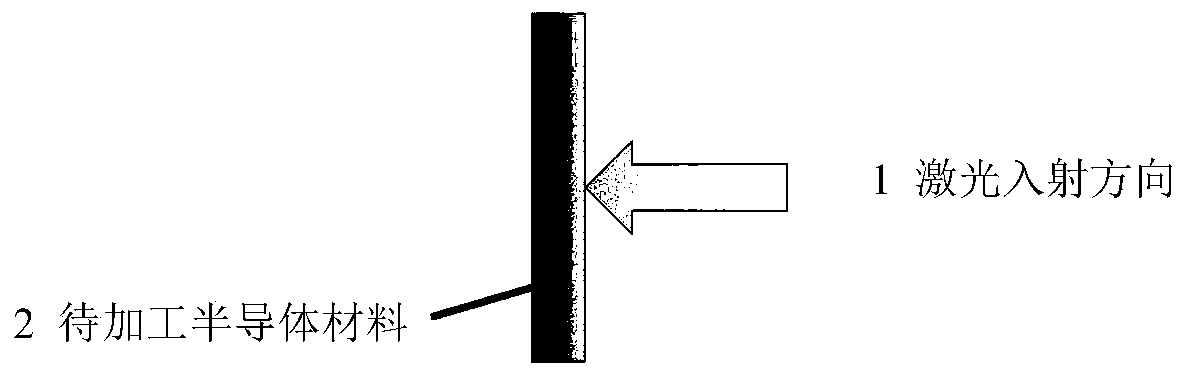

[0028] (2) A linearly polarized laser with a wavelength of 532 nm and a pulse width of 8 ps is selected as the active light source, and the laser is incident from the polished side (front side) of the Si substrate.

[0029] (3) Use a 150mm focal length lens to focus the laser beam so that the laser focus is located 10.5mm behind the polished surface.

[0030] (4) The laser energy density on the surface of the material is 0.17J / cm 2 .

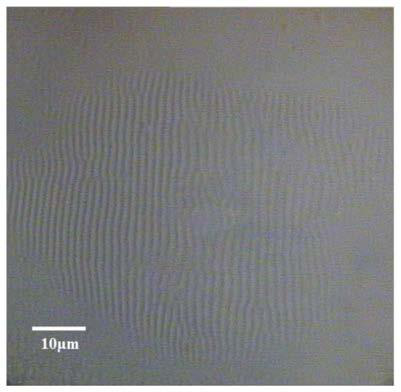

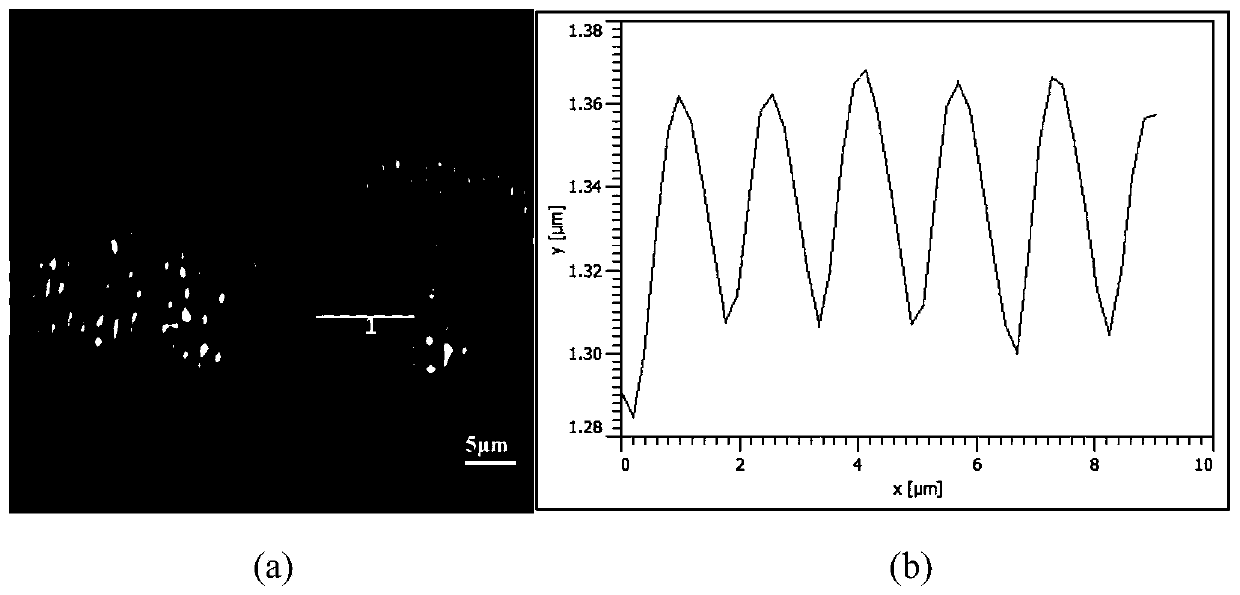

[0031] (5) Through 50 pulses of laser action, the intermediate layer, absorption layer and constrained layer medium in the laser irradiated area are removed at the same time, and the polished side surface on the Si substrate will produce LIPSS with a period betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com