A kind of on-demand oil-water separation membrane based on two-dimensional material and its preparation method

An oil-water separation membrane and two-dimensional material technology, which is applied in the field of on-demand oil-water separation membrane based on two-dimensional material and its preparation, can solve the problems of complex control process of separation membrane, lack of universality, stimulation of external conditions, etc. Excellent superhydrophobicity and water adhesion resistance, increased roughness, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

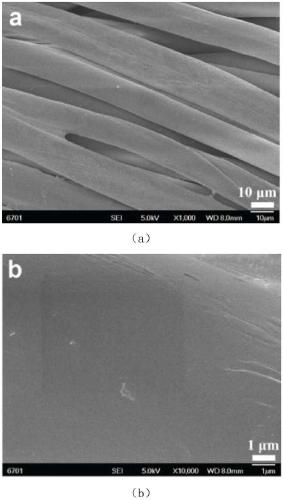

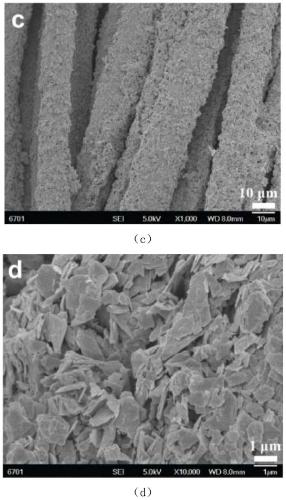

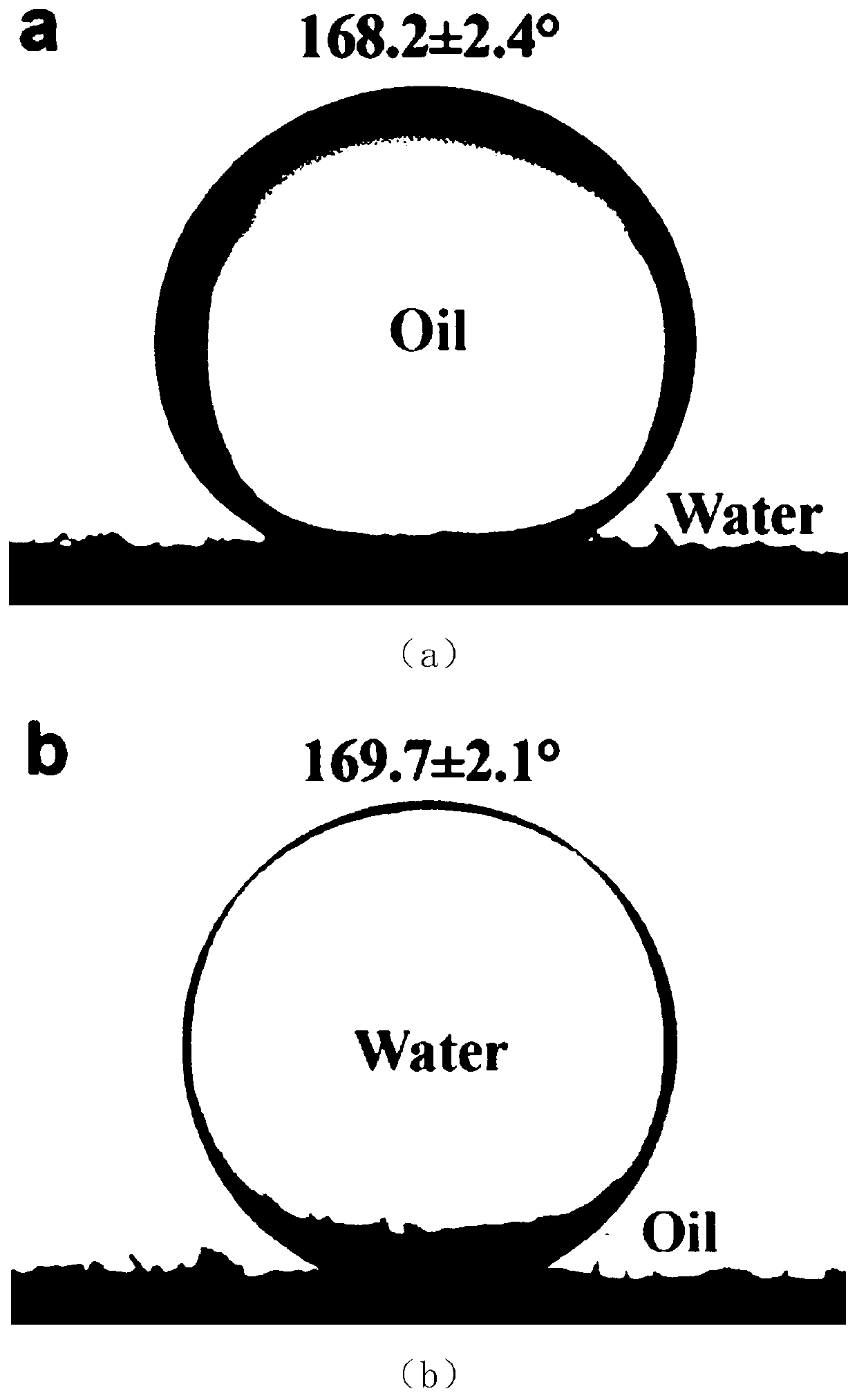

[0039] At room temperature, 4 g of molybdenum disulfide powder was placed in a 250 mL flask, and 200 mL of N-methylpyrrolidone was added into the flask, and ultrasonically treated for 8 hours. After allowing the resulting suspension to stand for 1 hour, the supernatant was carefully aspirated off. The suspension was vacuum filtered with PVDF membrane and washed with a large amount of ethanol. The exfoliated molybdenum disulfide nanosheets were vacuum-dried at room temperature, and then dispersed into a water-ethanol co-solvent with a volume ratio of 1:1 to prepare a suspension with a concentration of 5 mg / mL. Dip the cleaned cotton cloth into the suspension of molybdenum disulfide nanosheets, ultrasonicate for 5 minutes, take it out and dry it at 60°C, after drying, immerse the cotton cloth in the suspension of molybdenum disulfide nanosheets for 5 minutes, repeat the whole coating process 5 times, the separation membrane of the present invention can be obtained after drying....

Embodiment 2

[0047] At room temperature, 2 g of graphite powder was placed in a 250 mL flask, and then 200 mL of N,N-dimethylformamide was added into the flask, and ultrasonically treated for 4 hours. After allowing the resulting suspension to stand for 12 hours, the supernatant was carefully aspirated. The suspension was vacuum filtered through a PVDF membrane and washed with a large amount of ethanol. The obtained graphene nanosheets were vacuum-dried at room temperature, and then dispersed into a water-ethanol co-solvent with a volume ratio of 1:1 to prepare a suspension with a concentration of 8 mg / mL. The cleaned cotton cloth was immersed in the graphene nanosheet suspension, ultrasonicated for 8 minutes, taken out and dried at 50°C. After drying, the cotton cloth was dipped again into the graphene nanosheet suspension for 8 minutes. The whole coating process was repeated 3 times. Finally, the coated cotton cloth is dried to obtain the separation membrane of the present invention. ...

Embodiment 3

[0050] At room temperature, 1 g of boron nitride powder was placed in a 250 mL flask, then 200 mL of isopropanol was added into the flask, and ultrasonically treated for 6 hours. After allowing the resulting suspension to stand for 6 hours, the supernatant was carefully aspirated. The suspension was vacuum filtered through a PVDF membrane and washed with a large amount of ethanol. The exfoliated boron nitride nanosheets were vacuum-dried at room temperature, and then dispersed into a water-ethanol co-solvent with a volume ratio of 1:1 to make a suspension with a concentration of 10 mg / mL. The cleaned 500-mesh stainless steel mesh was immersed in the boron nitride nanosheet suspension, ultrasonicated for 3 minutes, taken out and dried at 40°C. After drying, the stainless steel mesh was dipped again into the boron nitride nanosheet suspension for 5 min. The whole coating process was repeated 4 times. Finally, drying can obtain the separation membrane of the present invention....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com