Preparation method for cobalt carbonate with aluminium adulteration

A cobalt carbonate and ammonium bicarbonate solution technology, applied in the direction of cobalt carbonate, etc., can solve the problems of poor dispersion and uneven particle size of cobalt carbonate, and achieve the effect of good dispersion, uniform particle size and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

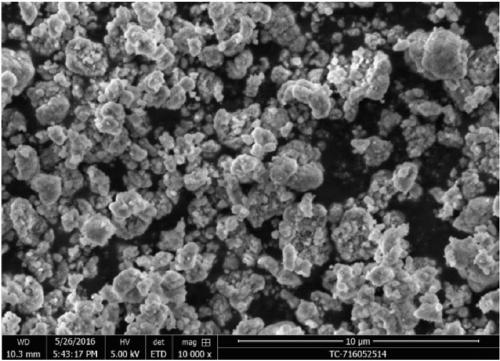

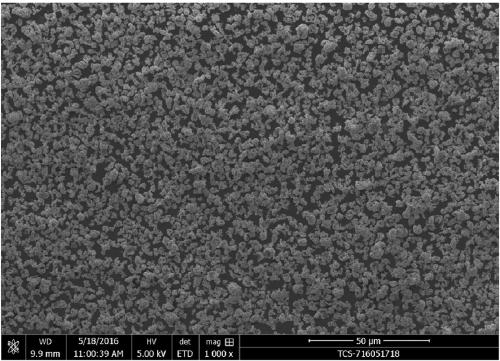

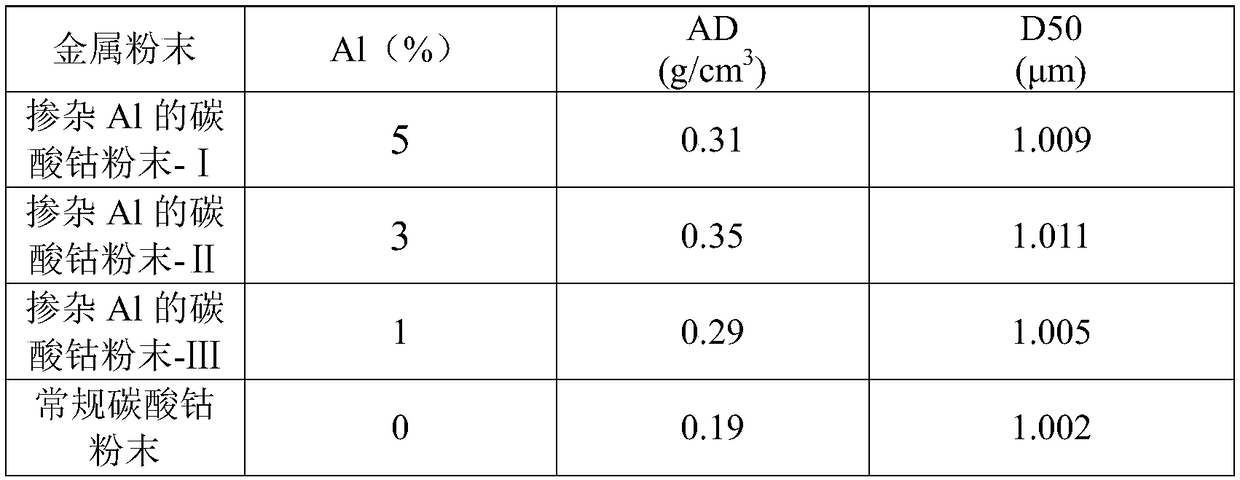

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing aluminum-doped cobalt carbonate, which is realized through the following steps:

[0033] Step 1, get a certain amount of cobalt chloride, add 50~70 ℃ of water to it, and stir to dissolve, be mixed with the cobalt concentration of cobalt and be the cobalt chloride solution of 108~112g / L; Get a certain amount of ammonium bicarbonate, Add water at 50-60°C, stir and dissolve, and prepare an ammonium bicarbonate solution with an ammonia concentration of 220-230g / L for later use; use water at a certain temperature to prepare cobalt chloride and ammonium bicarbonate solutions respectively, so that Cobalt chloride and ammonium bicarbonate have been fully dissolved, and the dispersibility of cobalt ions in the cobalt chloride solution and the dispersibility of carbonate ions in the ammonium bicarbonate solution have also been improved;

[0034] Step 2, adding aluminum chloride hexahydrate (AlCl 3 ·6H 2 O), stir evenly, obtain the d...

Embodiment 1

[0048] Step 1) Get a certain amount of cobalt chloride and put it into the solution tank, add water at 50°C therein, and stir and dissolve, and prepare a cobalt chloride solution whose concentration of cobalt (Co) is 108g / L; then take a certain amount Put the ammonium bicarbonate into another solution tank, add water at 50°C therein, and stir to dissolve, and prepare an ammonium bicarbonate solution with an ammonia concentration of 220g / L for subsequent use;

[0049] Step 2) Take 3L prepared cobalt chloride solution, and add 1340.78gAlCl 3 ·6H 2 O, stir evenly, obtain the doping cobalt chloride solution that the concentration of aluminum (Al) is 50g / L (5%);

[0050] Step 3) degreasing the prepared ammonium bicarbonate solution and the doped cobalt chloride solution respectively;

[0051] Step 4) Add 1.5L of pure water into the reactor as the bottom liquid, and heat the pure water so that the temperature of the bottom liquid reaches 50°C, and then add the doped cobalt chlorid...

Embodiment 2

[0056] Step 1) Get a certain amount of cobalt chloride and put it into the solution tank, add water at 60°C therein, and stir and dissolve to prepare a cobalt chloride solution whose concentration of cobalt (Co) is 110g / L; then take a certain amount Put the ammonium bicarbonate into another solution tank, add water at 55°C therein, and stir to dissolve, and prepare an ammonium bicarbonate solution with an ammonia concentration of 225g / L for subsequent use;

[0057] Step 2) Take 3L of prepared cobalt chloride solution, and add 804.74gAlCl 3 ·6H 2 O, stir evenly, obtain the doped cobalt chloride solution that the concentration of aluminum (Al) is 30g / L (3%);

[0058] Step 3) degreasing the prepared ammonium bicarbonate solution and the doped cobalt chloride solution respectively;

[0059] Step 4) Add 1.5L of pure water into the reactor as the bottom liquid, and heat the pure water to make the temperature of the bottom liquid reach 55°C, then add the doped cobalt chloride solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com