A low softening point lead-free glass composition and low-temperature lead-free sealing material and low-temperature lead-free solder paste comprising the glass composition

A technology of glass composition and lead-free glass, which is applied in the field of low-temperature lead-free sealing materials and low-temperature lead-free solder paste, which can solve the problems of no material available, increase of linear expansion coefficient, difficulty in popularization, etc., and achieve improved network structure composition , use performance reduction, optimize the effect of network composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

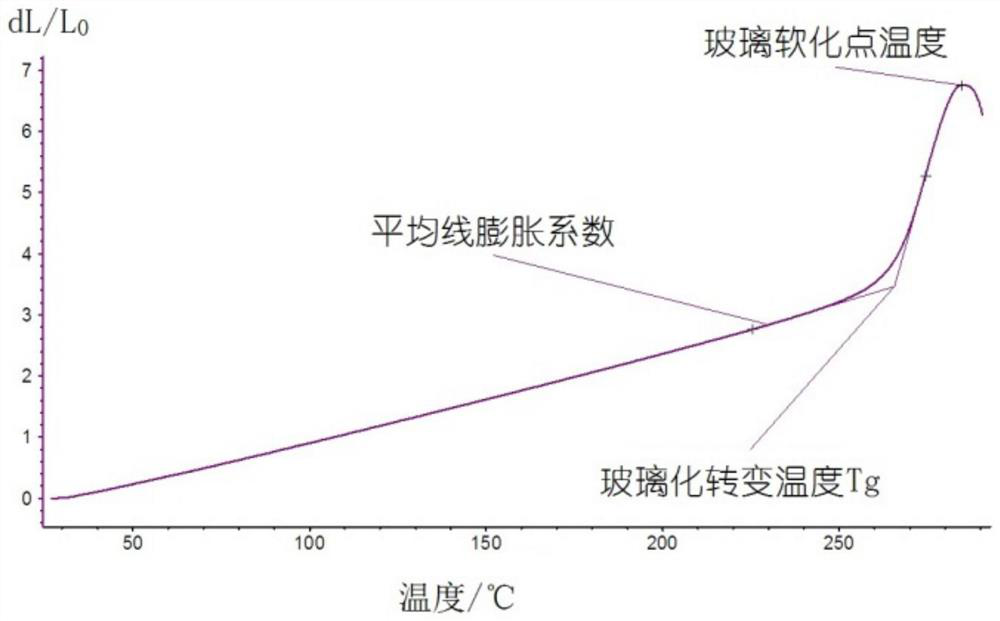

Image

Examples

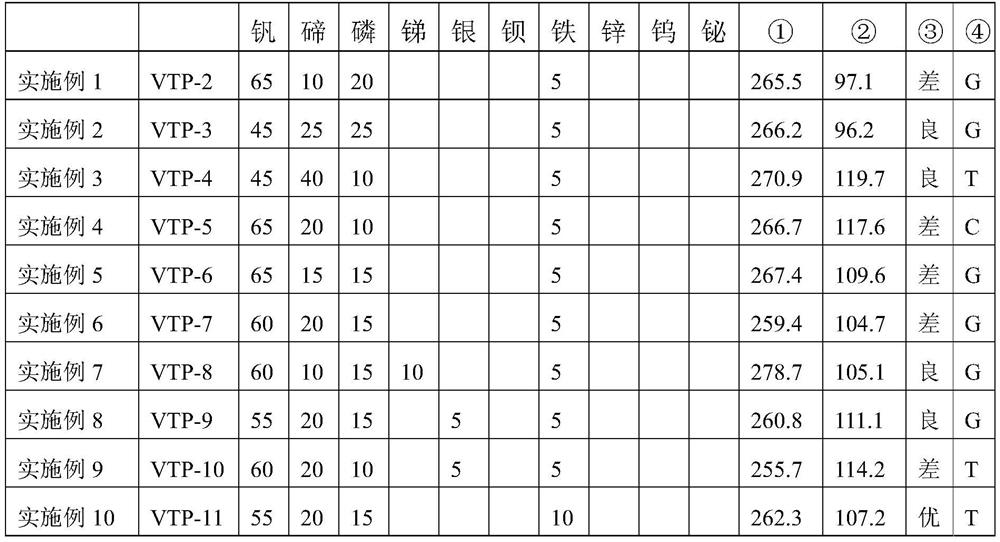

Embodiment 1-19

[0059] When the glass composition contains only vanadium and, the glass is easily crystallized, and the moisture resistance is poor, and the third and above elements must be contained.

[0060] When the third element phosphor is contained, the softening temperature of the glass is raised as the vanadium content is lowered, and when the vanadium content exceeds 65% by weight, the moisture resistance is deteriorated; when the phosphorus content is less than 5% by weight, it is easy to generate crystallization. It also affects the low temperature fluidity of the glass, and when the phosphorus content exceeds 25% by weight, the softening point of the glass will rise.

[0061] Further, in order to improve the moisture resistance of the glass, the wire expansion coefficient is lowered, and the present invention proposes to introduce a metal or an alkaline earth metal oxide in the glass, with barium, tungsten, ferroxide to improve the moisture resistance, but the content exceeds 15% by w...

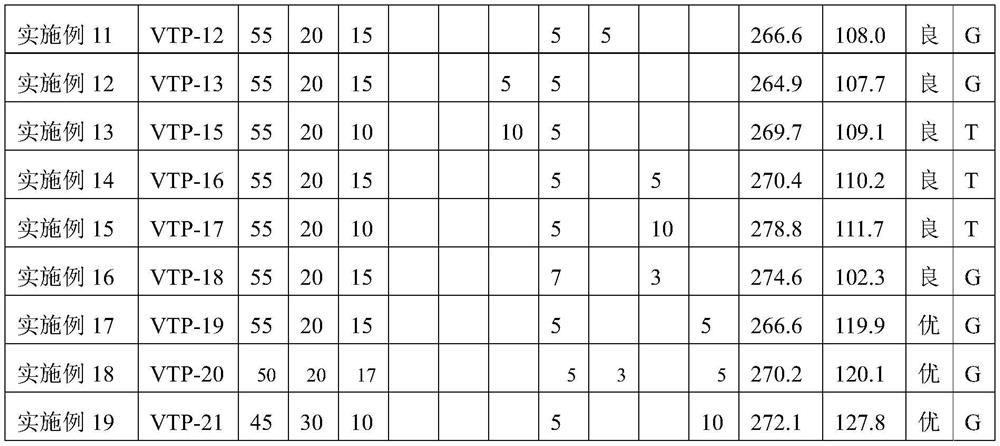

Embodiment 20-34

[0071] Further, based on the above-described Embodiments 1-19, the present invention is further reduced the wire expansion coefficient of the glass while improving the fluidity and infiltration of the surface of the low softened point glass, improve its chemical stability and water resistance, and preferred A low softened point glass composition is proposed, which mainly contains vanadium,,, aluminum, barium oxide, and the softening point of the glass composition is 300 ° C or lower, and 25 ° C of the glass composition. ~ 250 ° C linear wire expansion coefficient is 120 × 10 -7 / ° C or less.

[0072] The composition of the low softening point lead-free glass composition of the vanadium aluminum system is shown in Table 2. Among them, any component is represented according to the weight ratio shown in the oxide conversion, which contains vanadium,, aluminum, as a glass raw material, vanadium using V. 2 O 5 , Use TEO 2 Aluminum uses Al 2 O 3 At the same time, add modified component...

Embodiment 35

[0082] As a further embodiment, the study of hybrid filler is carried out for the low softening point lead-free glass composition, including the types and content of the filler. The VTP-7, 17, 21 of Table 1 in the above examples is typically representing a glass milling and over 300 mesh sieves, and a fine powder having a particle size of less than 50 microns is obtained. Further, the present embodiment is only 30 micromerates as a ceramic filler, and the low softening point glass composition powder and the ceramic filler are mixed in accordance with the weight ratio of 10: 1, 10: 2, 10: 3, and mixed the mixed powder. Study its softening temperature, change in flow flooding temperature and line expansion coefficient.

[0083] Filler, ratio and mixed material characteristics used in the examples

[0084]

[0085] As can be seen from the test results, as the added ratio of cordierite ceramic filler increases, the linear expansion coefficient of the glass mixture gradually decrease...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com