Preparation method of high-strength waterproof easy plaster

A kind of beneficial glue and high-strength technology, which is applied in the field of preparation of high-strength waterproof and beneficial glue, can solve the problems of poor waterproof ability, tolerance ability and bonding strength, and achieve the advantages of small ion diffusion rate, optimized pore structure, and increased content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

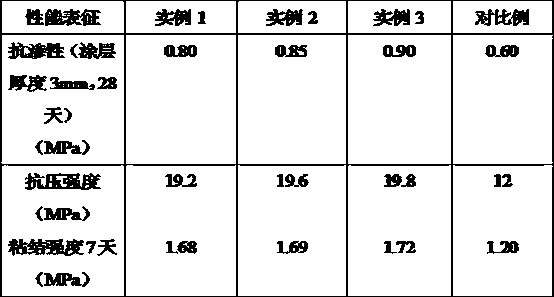

Examples

example 1

[0019] Put the waste concrete in a mechanical mixer and mechanically stir for 2 hours to obtain coarse aggregate, soak the coarse aggregate in a 5% polyvinyl alcohol solution for 8 hours, take it out, and dry it in an oven at a temperature of 50°C to constant weight and cooled to room temperature to obtain the modified coarse aggregate; in parts by weight, weigh 40 parts of modified coarse aggregate, 20 parts of cement, 1 part of acrylic rubber powder, 10 parts of silica sol, 5 parts Carbon fiber, 0.3 parts of hydroxyethyl methylcellulose, 70 parts of deionized water, and a mass fraction of 1% borax solution are mixed with silica sol and carbon fiber, and stirred at a stirring speed of 100r / min for 30min to obtain a composite sol. Mix the permanent coarse aggregate, cement and deionized water evenly to obtain a suspension. Add the borax solution with a mass fraction of 1% to the suspension at a stirring speed of 60r / min. Stir for 1 hour to obtain a base liquid. Mix the composi...

example 2

[0021] Put the waste concrete in a mechanical mixer and mechanically stir for 2.5 hours to obtain coarse aggregate, soak the coarse aggregate in a 5% polyvinyl alcohol solution for 9 hours, take it out, and place it in an oven at a temperature of 55°C Dry to constant weight and cool to room temperature to obtain modified coarse aggregate; in parts by weight, weigh 50 parts of modified coarse aggregate, 25 parts of cement, 3 parts of acrylic rubber powder, 14 parts of silica sol, 6 parts of 1 part of carbon fiber, 0.45 part of hydroxyethyl methylcellulose, 85 parts of deionized water, the mass fraction is 1% borax solution, the silica sol and carbon fiber are mixed, and the stirring speed is 200r / min and stirred for 35min to obtain a composite sol. The modified coarse aggregate, cement and deionized water were mixed evenly to obtain a suspension, and the mass fraction of 1% borax solution was added dropwise to the suspension at a stirring speed of 70r / min, and stirred for 2 hour...

example 3

[0023] Place waste concrete in a mechanical mixer for 3 hours to obtain coarse aggregate, soak the coarse aggregate in a 5% polyvinyl alcohol solution for 10 hours, take it out, and dry it in an oven at 60°C to constant weight and cooled to room temperature to obtain the modified coarse aggregate; in parts by weight, weigh 60 parts of modified coarse aggregate, 30 parts of cement, 5 parts of acrylic rubber powder, 18 parts of silica sol, 7 parts Carbon fiber, 0.6 parts of hydroxyethyl methylcellulose, 100 parts of deionized water, and a mass fraction of 1% borax solution were mixed with silica sol and carbon fiber, and stirred at a stirring speed of 300r / min for 40min to obtain a composite sol. Mix the permanent coarse aggregate, cement and deionized water evenly to obtain a suspension. Add the borax solution with a mass fraction of 1% to the suspension at a stirring speed of 80r / min. Stir for 3 hours to obtain a base liquid. Mix the composite sol and the base liquid, stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com